A blown film equipment suitable for biodegradable materials

A biodegradable material and equipment technology, applied in the field of film blowing equipment, can solve the problems of low heating degree, uneven heating of the blown film die head, and affecting the quality of blown film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

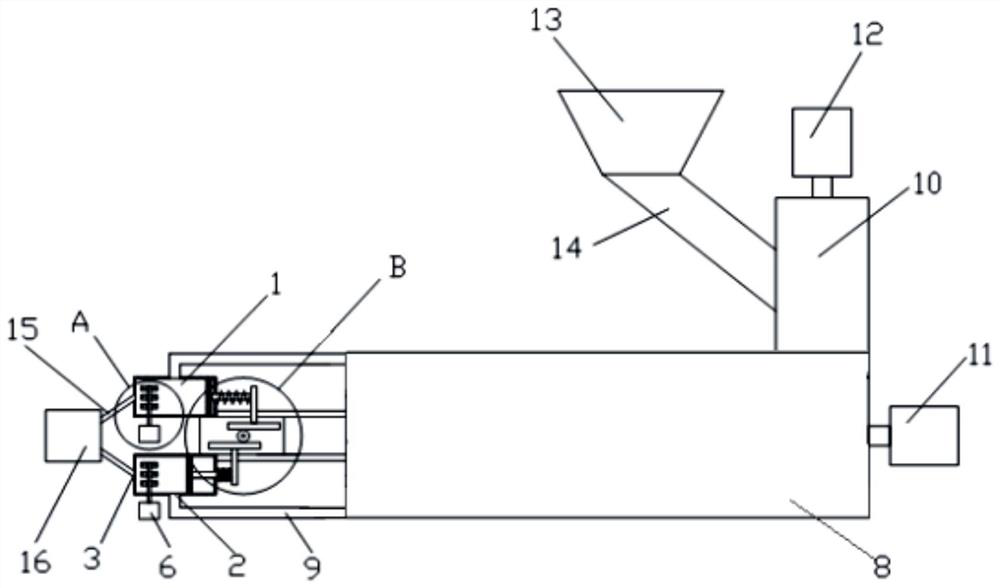

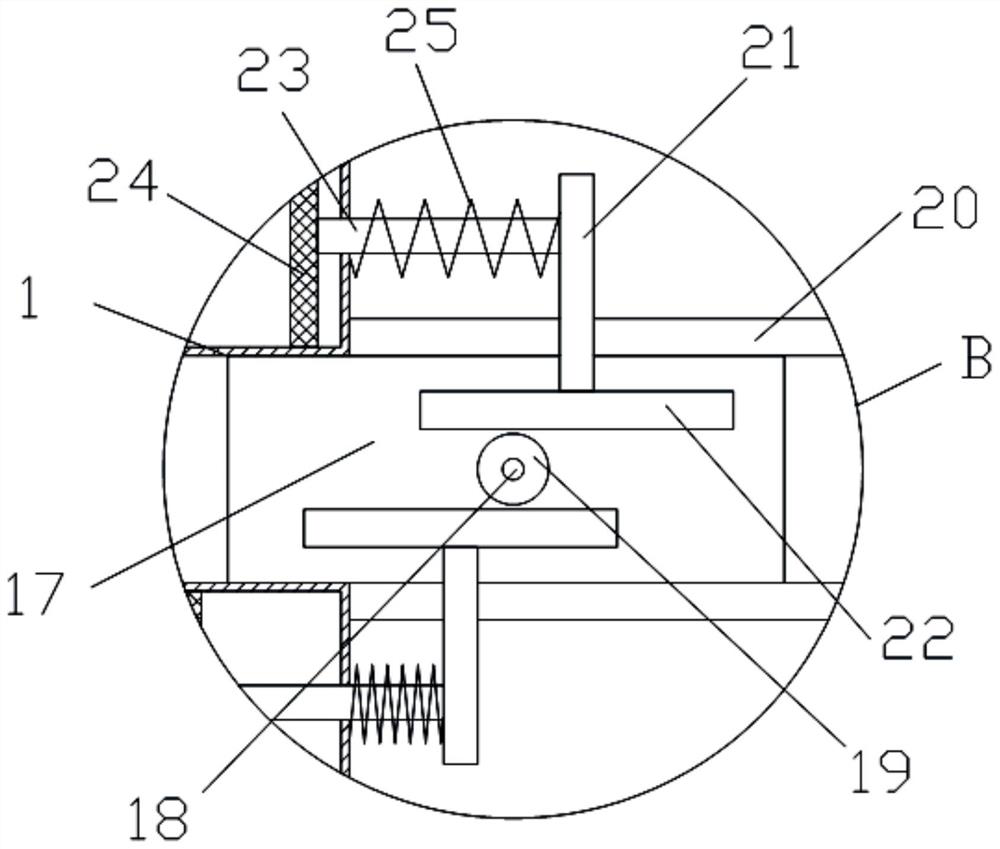

[0074] Embodiments of the present invention provide a film blowing equipment suitable for biodegradable materials, such as Figure 1-Figure 3 shown, including:

[0075] A heating box 1, the inner wall of the heating box 1 is provided with several heating rods, the heating box 1 is provided with a feed port 2 and a discharge port 3, and the inside of the heating box 1 is also provided with a stirring shaft 4, and the stirring shaft 4 is provided with a stirring blade 5, the outside of the heating box 1 is provided with a first motor 6, the output shaft of the first motor 6 extends through the outer wall of the heating box 1 to the inside of the heating box 1 and is connected with the stirring One end of the shaft 4 is fixedly connected.

[0076] The invention is suitable for blown film manufacture of biodegradable materials, and the biodegradable materials can be existing polylactic acid (PLA) and polyterephthalic acid-adipate-butylene glycol ester (PBAT).

[0077] The workin...

Embodiment 2

[0079] On the basis of embodiment 1

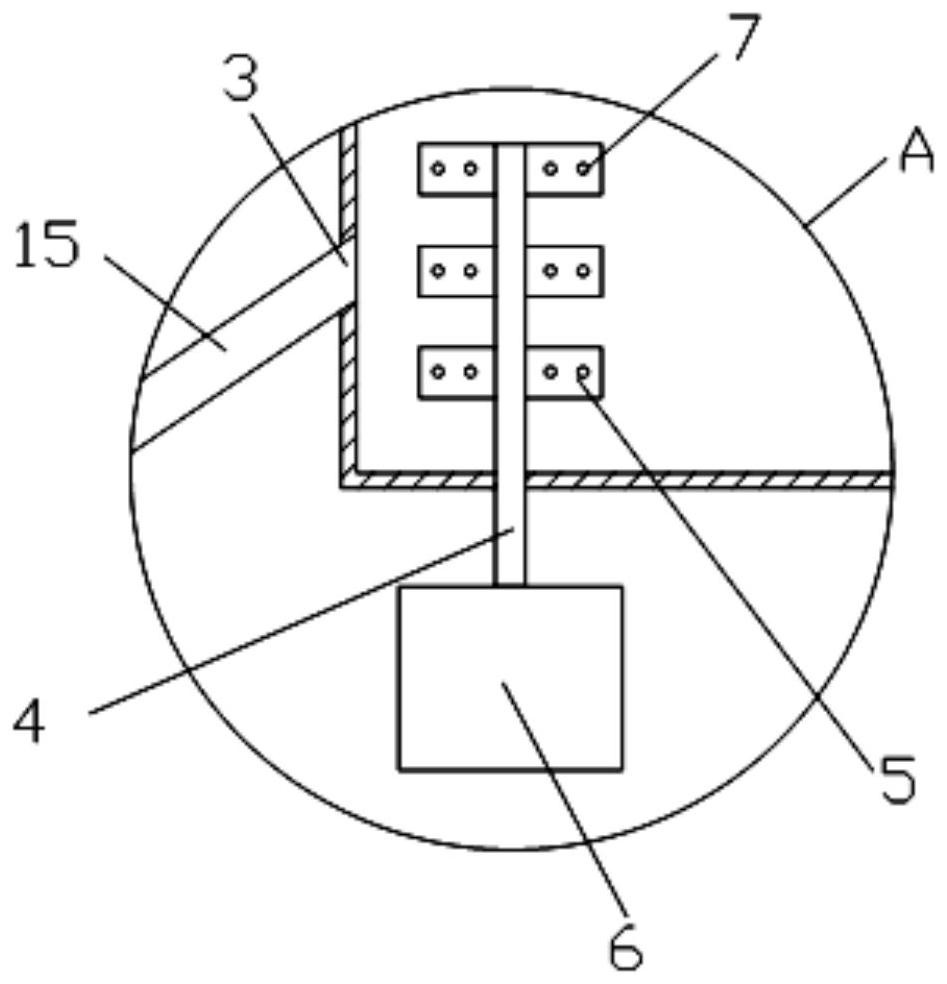

[0080] Such as figure 2 As shown, the stirring blades 5 are installed on the periphery of the stirring shaft 4, and there are several stirring blades 5, and the surfaces of several stirring blades 5 are all provided with first through holes 7.

[0081] The working principle and beneficial effects of the above-mentioned technical solution are as follows: a number of stirring blades 5 are evenly distributed on the periphery of the stirring shaft 4, and a number of blades are arranged so that the stirring shaft 4 in the heating box 1 can stir more biodegradable materials. The first through hole 7 is arranged on the top, which can reduce the resistance when the stirring shaft 4 rotates, speed up the stirring speed, shorten the time for uniform mixing, and save the power of the first motor 6 .

[0082] Preferably, a first one-way valve is set in the inlet 2, and a second one-way valve is set in the outlet 3.

[0083] The working principle an...

Embodiment 3

[0085] On the basis of embodiment 1 or 2

[0086] Such as figure 1As shown, an extrusion box 8 is also included, and the extrusion box 8 is communicated with the feed port 2 through a first connecting pipe 9, and a feed box 10 is arranged on the upper end of the extrusion box 8, and the feed box 8 The lower end of 10 communicates with the upper end of the extrusion box 8; an extrusion screw is arranged inside the extrusion box 8, and the right end of the extrusion screw extends to the outside of the extrusion box 8 and is fixedly connected with the output end of the second motor 11. Others, the principle of film blowing can refer to 201420463675.5, and will not be repeated here.

[0087] The working principle and beneficial effects of the above technical solution are: the biodegradable material enters the extrusion box 8 from the feed box 10, and then is extruded into the heating box 1 from the extrusion box 8, so that the filtration and screening of the biodegradable materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com