Silver sheet processing device for manufacturing porcelain-coated silver wine glass

A processing device and wine glass technology, which is applied in manufacturing tools, other manufacturing equipment/tools, glass production, etc., can solve the problems of manpower consumption, low work efficiency, cumbersome operation process, etc., to improve work efficiency, simple operation, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

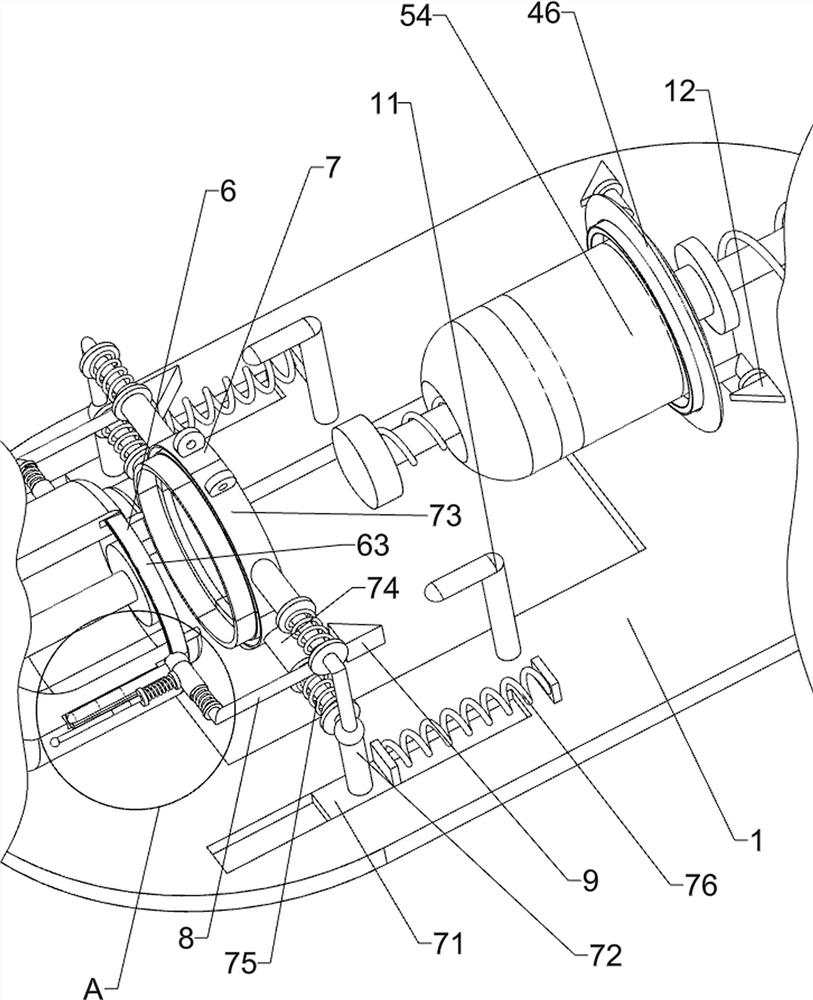

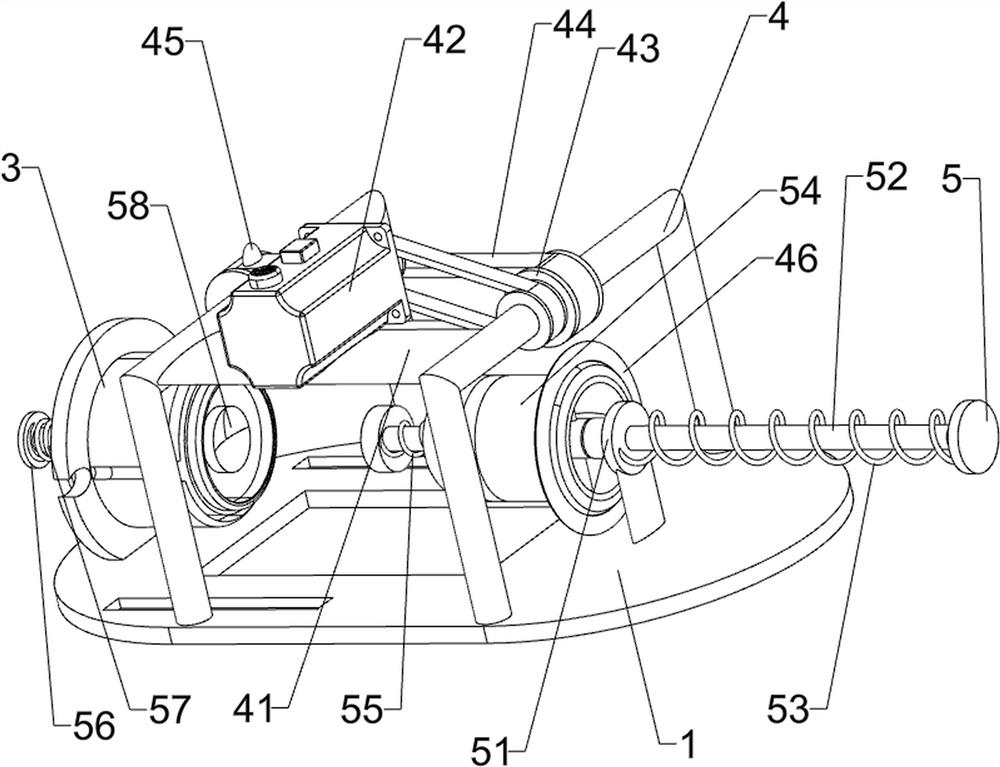

[0025] A silver sheet processing device for making porcelain-clad silver wine glasses, such as Figure 1-2 As shown, it includes a bottom plate 1, a support plate 2 and an inner concave barrel 3. The bottom of the bottom plate 1 is connected with the support plate 2, and the front side of the top of the bottom plate 1 is connected with the inner concave barrel 3. It also includes a driving mechanism 4 and a forming mechanism 5. The bottom plate 1 is provided with a driving mechanism 4, and a forming mechanism 5 is provided between the bottom plate 1 and the inner concave barrel 3, and the driving mechanism 4 is connected to the forming mechanism 5 through transmission.

[0026] Forming mechanism 5 comprises slide tube 51, slide bar 52, tension spring 53, pressure roller 54, return spring 55, cross bar 56, compression spring 57 and push plate 58, bottom plate 1 top rear side is connected with slide tube 51, slide tube Slide bar 52 is connected with slide bar 51 in 51, is connec...

Embodiment 2

[0030] On the basis of Example 1, such as image 3 As shown, it also includes a crimping mechanism 7, and the crimping mechanism 7 includes a slider 71, a connecting frame 72, an arc snap ring 73, a connecting sleeve 74, a first spring 75 and a second spring 76, and the left and right sides of the top of the base plate 1 The sides are evenly slidably connected with a slider 71, the top of the slider 71 is connected with a connecting frame 72, the connecting frame 72 is slidably connected with a connecting sleeve 74, and the connecting sleeve 74 is connected with an arc-shaped snap ring 73, and the arc-shaped snap ring 73 and The pressure roller 54 cooperates, a first spring 75 is connected between the connecting sleeve 74 and the connecting frame 72 , and a second spring 76 is connected between the slider 71 and the bottom plate 1 .

[0031] When placing the preliminarily processed silver sheet, the silver sheet can be stuck between the arc-shaped snap rings 73 on both sides. ...

Embodiment 3

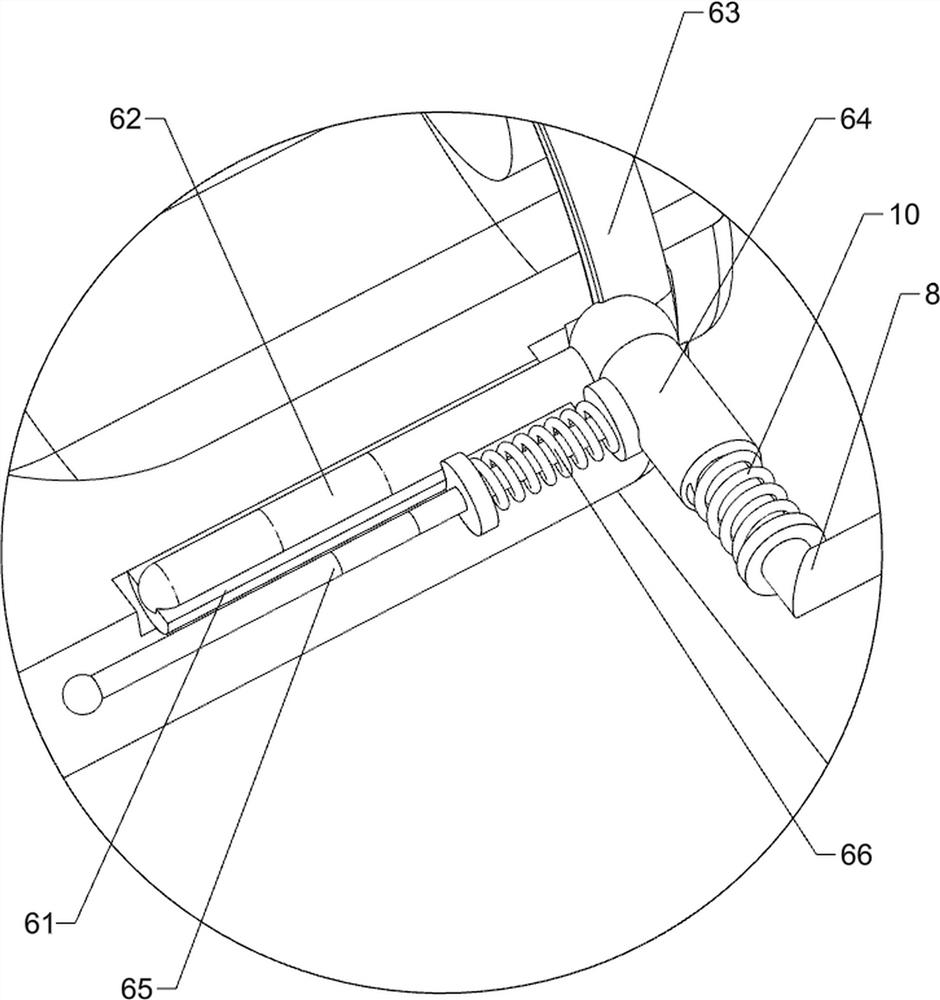

[0033] On the basis of Example 2, such as Figure 3-4As shown, a cutting mechanism 6 is also included, and the cutting mechanism 6 includes a slide tube 61, a guide rod 62, an annular cutter 63, a sleeve pipe 64, a connecting rod 65 and an elastic member 66, and the left and right sides of the inner concave barrel 3 are connected. There is a slide tube 61, a guide rod 62 is slidingly connected in the slide tube 61, an annular cutter 63 is connected between the guide rods 62 on both sides, a sleeve 64 is connected to the guide rod 62, and a connecting rod 65 is connected to the sleeve 64 , An elastic member 66 is connected between the sliding tube 61 and the casing 64 .

[0034] After the cup edge portion of the silver sheet is processed, there will be some corners. At this time, the push plate 58 will release the silver sheet, and the released silver sheet will be stuck between the arc snap rings 73 on both sides. Pull the ring cutter 63 to move backward, and the elastic memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com