Device and method of milling head with feeding type multi-shaft output drilling bodies

A multi-axis output and milling head technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high precision requirements, low processing efficiency, small processing space, etc., to meet special requirements, improve processing efficiency, reduce The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

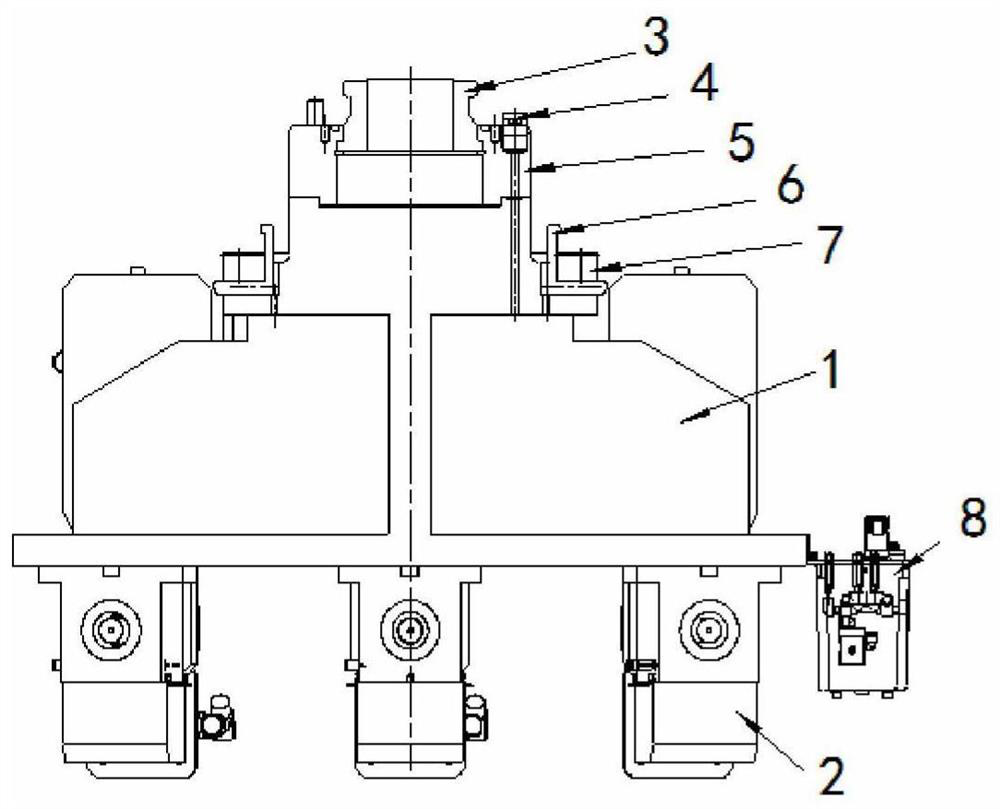

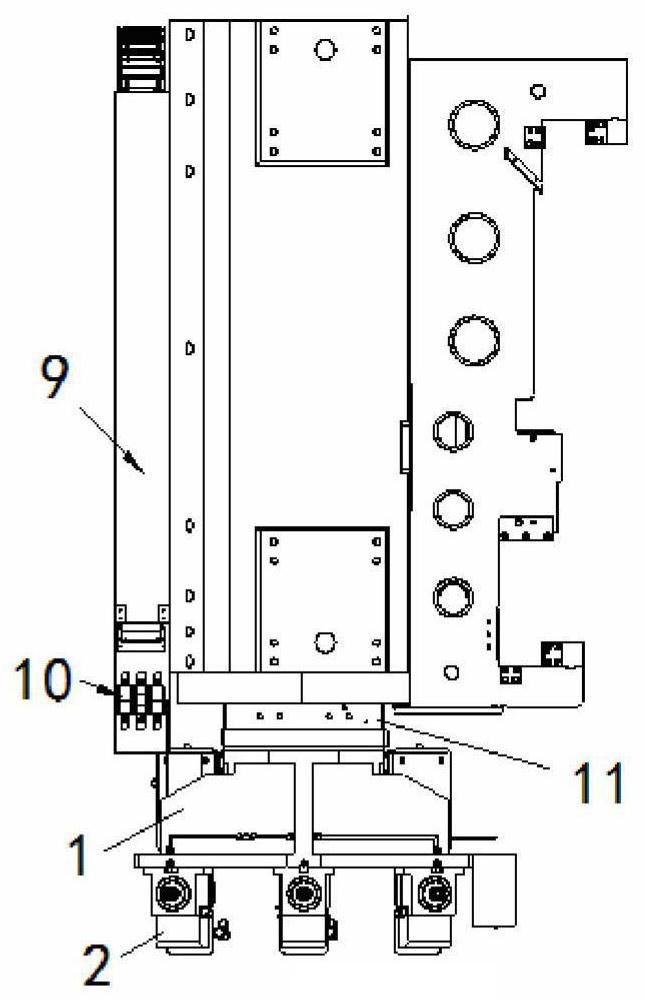

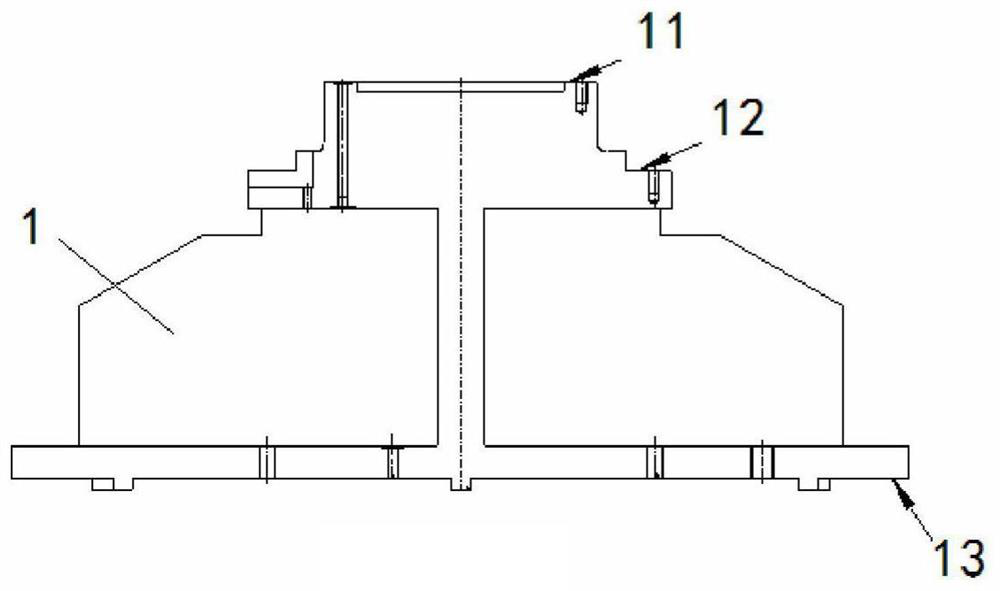

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a drilling and milling head device with multi-axis output with feed, the connecting piece 1 is connected with the sleeve 5 through the screw, the connecting piece 1 is mechanically connected with the pull stud 3 through the sleeve 5, the pull stud 3 is connected with the ram 11, and the end The tooth plate 7 is connected with the connecting body 1, the safety pin 6 is connected with the end tooth plate 7, the upper surface of the sleeve 5 is connected with the quick-change joint 4, the mechanical quantitative lubrication device 8 is connected with the connecting piece 1, and the connecting piece 1 is connected with the sleeve 5 through screws Connected with the ram 11, the upper end surface 12 of the connector 1 is installed with the end sprocket 7, the end sprocket 7 meshes with the lower end surface of the ram, and the pipeline is installed in the drag chain 9, and the pipeline is connected with the modular e...

Embodiment 2

[0023] Embodiment 2: as figure 1 , figure 2 , image 3 As shown, a drilling and milling head device with multi-axis output with feed, the drilling and tapping power head 2 is connected with the connecting piece 1, and combined and installed together to form a special accessory head.

[0024] The connecting piece 1 is connected with the sleeve 5 through the screw, the connecting piece 1 is mechanically connected with the pull rivet 3 through the set 5 , and the pull rivet 3 is connected with the ram 11 .

[0025] The end sprocket 7 is connected with the connecting piece 1 to realize multi-angle indexing of the attachment head.

[0026] The safety pin 6 is connected with the end sprocket 7, and the safety pin 6 can play a mechanical locking effect when the special accessory head is connected with the ram 11 through the thrust action of the internal spring, so as to prevent the special accessory head from falling off accidentally.

[0027] The upper end surface of the sleeve ...

Embodiment 3

[0047] Embodiment 3: as figure 1 , figure 2 , image 3 As shown, a device and method for a multi-axis output drilling and milling head with feed, including the following steps:

[0048] Three power heads with feed drilling and tapping are used to assemble with the connecting body along the set angle of 6°, which are used as special accessory heads for machine tools.

[0049] Compress the bottom dimensional space of the drilling and tapping power head to avoid the interference between the ram and the inner arc surface of the part. At the place where the main shaft can be close to the bevel at the lower end of the part, drilling and tapping can be carried out at the same time, and the spindle motor shaft is assembled The 1:1 synchronous pulley drives the main shaft to rotate through spline cooperation.

[0050] The feed servo motor drives the ball screw to push the sleeve. The internal bearing of the main shaft is lubricated with long-term grease. The telescopic sleeve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com