Centrifugal filter unit for horizontal centrifuge

A horizontal centrifuge and centrifugal filtration technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problem of easy clogging of sieve holes, achieve easy clogging, ensure smooth flow, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

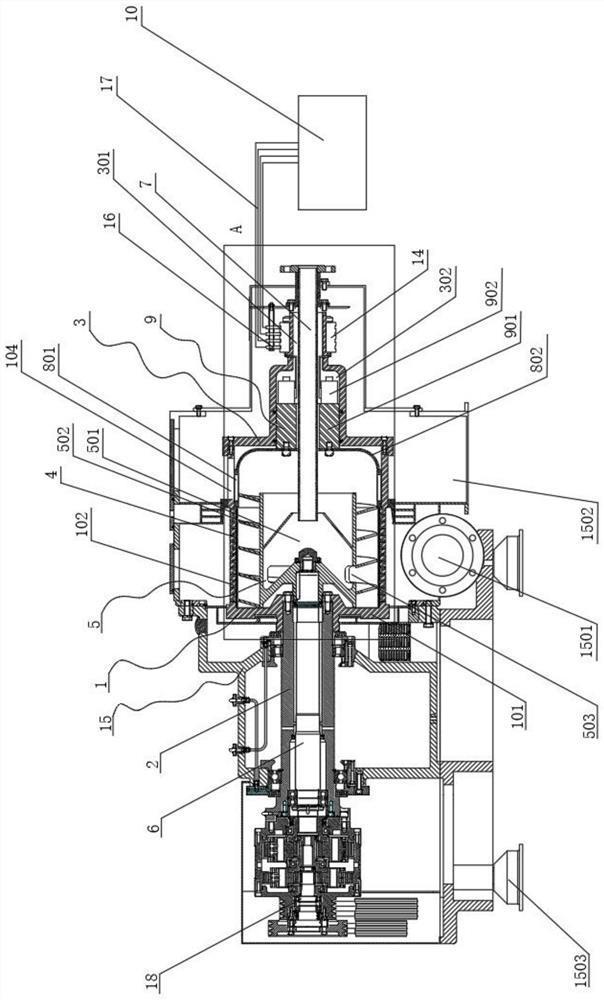

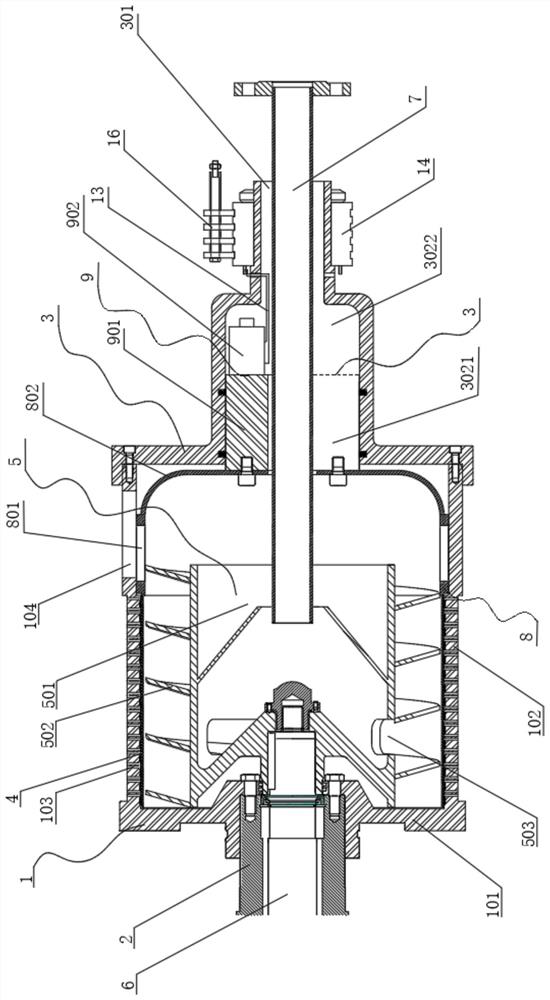

[0046] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0047] Figure 1 to Figure 4 , Figure 13 and Figure 14 As shown, the first embodiment of the centrifugal filter device of the horizontal centrifuge includes the drum 1 of the centrifuge. The drum 1 is enclosed by a circular drum bottom 101 and a barrel-shaped drum wall 102. The drum 1 is connected with one end of the hollow rotating shaft 2 through the drum bottom 101, and the other end of the hollow rotating shaft 2 is connected with the differential transmission device 18. The upper port of the rotating drum 1 is provided with a flange 3, and the outer edge of the flange 3 is connected to the rotating shaft. The upper ports of the drum wall 102 are matched and fixedly connected, and a flange center hole 301 is arranged along the central axis of the flange 3. A number of liquid outlet holes 103 are evenly opened on the drum wall 102, and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com