All-solid-state lithium battery positive electrode sheet and preparation method thereof, and all-solid-state lithium battery

A positive electrode, lithium battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor battery rate performance and capacity volatility, poor lithium ion conductivity, and large interface resistance of positive electrodes. The effect of low impedance, simple preparation process and high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

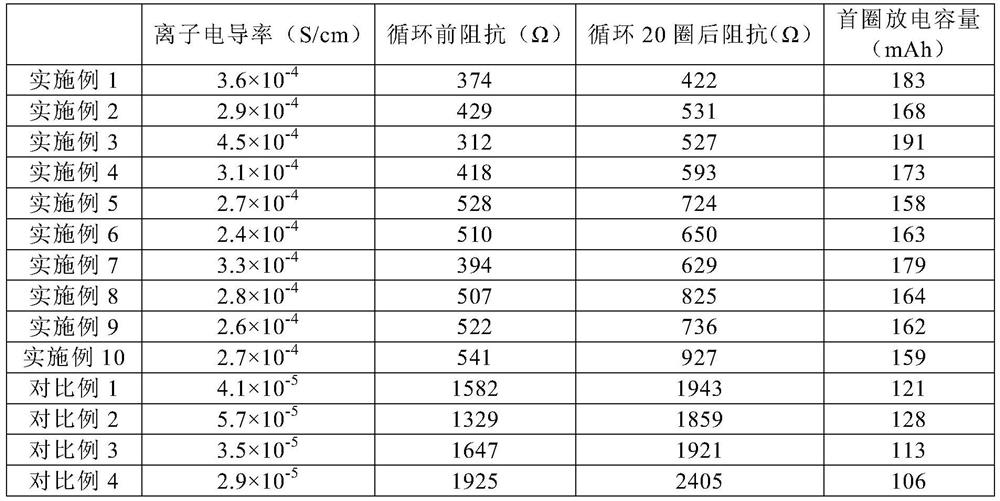

Examples

Embodiment 1

[0032] The positive electrode sheet of the all-solid-state lithium battery in this embodiment, its functional layer is formed from 80 parts of lithium cobalt oxide, 5 parts of carbon nanotubes, 5 parts of PVDF, and 10 parts of composite solid electrolyte, and is specifically prepared according to the following preparation process:

[0033] (1) LiCl and BCl with a molar ratio of 3:1 3 Dissolved in THF solvent and dried to obtain Li 3 BCl 6 (solid electrolyte); the Li 3 BCl 6 As a target, it was sputtered on Li 3 PO 4 particles, and then heated at 200°C for 8 hours in a dry environment to obtain a composite solid electrolyte with a core-shell structure;

[0034] (2) Add 80 parts of lithium cobaltate, 5 parts of carbon nanotubes and 5 parts of PVDF (dissolve PVDF in NMP first to form a 5wt% solution, take 100 parts of the 5wt% solution) and mix in 100 parts of NMP Uniformly form a slurry, add 10 parts of the above-mentioned composite solid electrolyte to the slurry, mix uni...

Embodiment 2

[0036] The positive electrode sheet of the all-solid-state lithium battery provided in this example, its functional layer is formed from 85 parts of lithium cobalt oxide, 4 parts of carbon nanotubes, 1 part of PVDF binder and 10 parts of composite solid electrolyte, specifically according to the following preparation process have to:

[0037] (1) LiCl and AlCl with a molar ratio of 3:1 3 Dissolved in water and dried to give Li 3 AlCl 6 ; Will Li 3 AlCl 6 As a target, it was sputtered on Li 3 PO 4 particles, and then heated at 300°C for 8 hours in a dry environment to obtain a composite solid electrolyte with a core-shell structure;

[0038] (2) Referring to the method of step (2) in Example 1, according to the mass parts of the raw materials of each functional layer in the present example above, an all-solid-state lithium battery positive electrode sheet was prepared.

Embodiment 3

[0040] The positive electrode sheet of the all-solid-state lithium battery provided in this example, its functional layer is formed from 82 parts of lithium iron phosphate, 6 parts of acetylene black, 2 parts of PVDF, and 10 parts of composite solid electrolyte, and is specifically prepared according to the following preparation process:

[0041] (1) LiCl and GaCl with a molar ratio of 3:1 3 Dissolved in water and dried to give Li 3 GaCl 6 solid electrolyte; the Li 3 GaCl 6 As a target, it was sputtered on Li 0.3 B 0.9 PO 4 particles, and then heated at 300°C for 8 hours in a dry environment to obtain a composite solid electrolyte with a core-shell structure;

[0042] (2) Referring to the method of step (2) in Example 1, according to the mass parts of the raw materials of each functional layer in the present example above, an all-solid-state lithium battery positive electrode sheet was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com