Thin film drying method, thin film drying device, and device including thin film

A drying method and drying device technology, which are applied in the manufacturing of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of affecting device performance and poor compactness of material film layers, and achieve the effect of improving related performance and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

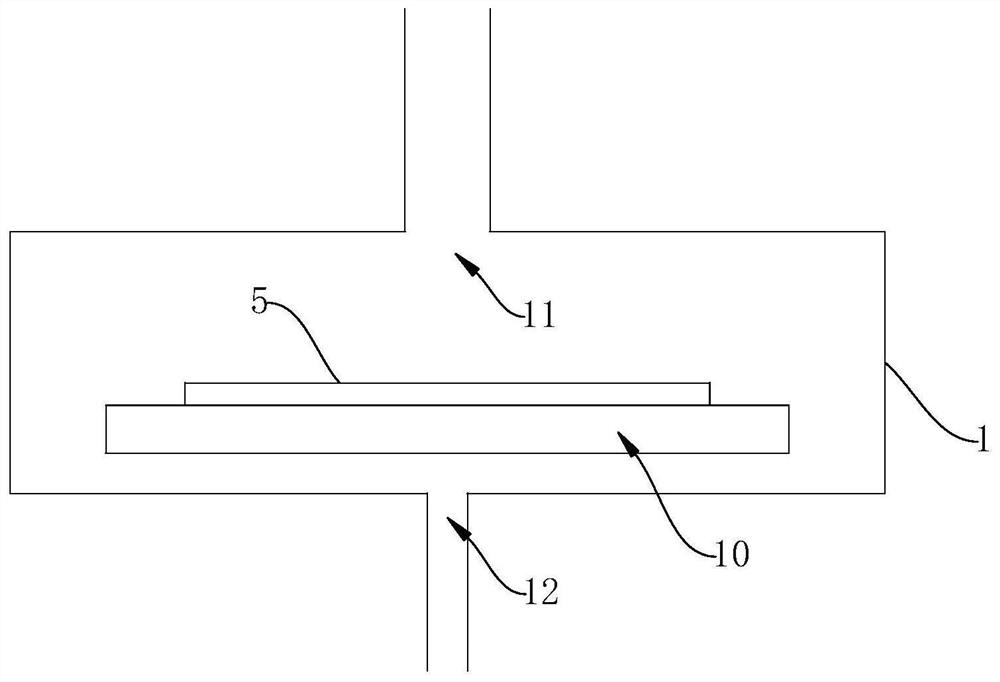

Image

Examples

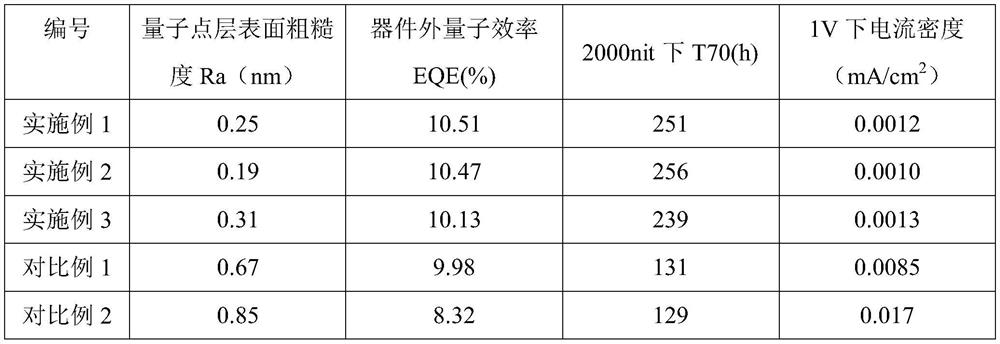

Embodiment 1

[0067] (1) Preparation of semi-finished products of QLED devices: On 30*30mm ITO glass, spin-coat PEDOT with a thickness of 40nm and poly(9-vinylcarbazole) (PVK) with a thickness of 30nm in sequence and dry them; print with DMP2831 desktop The equipment prints green quantum dot ink on the dried PVK surface under the condition of 30 μm drop interval, the concentration of quantum dots in the quantum dot ink is 1wt%, the solvent in the quantum dot ink includes nonane and octanol The volume ratio is nonane:octanol=7.5:2.5, and the thickness of the wet film after printing is about 50nm.

[0068] (2) Dry the semi-finished QLED device above: place the printed green quantum dot ink substrate at room temperature T 1 , Atmospheric pressure P 1 (P 1 = 1 bar, T 1 =25°C) in the cavity, after the cavity is sealed, nitrogen gas is introduced to increase the pressure in the cavity to P 2 , P 2 =100bar, then turn on the heating to raise the substrate temperature to T 2 ,T 2 =100°C; then...

Embodiment 2

[0071] (1) The method for preparing the QLED device semi-finished product is the same as the step (1) of Example 1.

[0072] (2) Dry the above-mentioned QLED device semi-finished products: place the substrate printed with green quantum dot ink at room temperature T 1 , Atmospheric pressure P 1 (P 1 = 1 bar, T 1 = 25°C), after the cavity is sealed, nitrogen and octanol saturated vapor at 25°C are introduced to increase the pressure in the cavity to P 2 , P 2 =100bar, then turn on the heating to raise the substrate temperature to T 2 ,T 2 =100°C; then gradually reduce the pressure in the cavity to normal pressure P at a rate of 0.1bar / s 1 after 10 -5 The decompression rate of bar / s reduces the chamber pressure to P 3 , P 3 =10 -4 bar, after maintaining the air pressure for 30 minutes, turn off the heating, inject nitrogen gas to restore the cavity pressure to normal pressure, and continue to inject nitrogen gas to lower the cavity temperature. After it returns to norma...

Embodiment 3

[0075] (1) The method for preparing the QLED device semi-finished product is the same as the step (1) of Example 1.

[0076] (2) Dry the above-mentioned QLED device semi-finished products: place the substrate printed with green quantum dot ink at room temperature T 1 , Atmospheric pressure P 1 (P 1 = 1 bar, T 1 =25°C) in the cavity, after the cavity is sealed, nitrogen gas is introduced to increase the pressure in the cavity to P 2 , P 2 =100bar, then turn on the heating to raise the substrate temperature to T 2 ,T 2 =100°C; then gradually reduce the pressure in the cavity to normal pressure P at a rate of 0.1bar / s 1 after 10 -5 The decompression rate of bar / s reduces the chamber pressure to P 3 , P 3 =10 -4 bar, then increase the substrate temperature to T 3 ,T 3 =150°C, after maintaining the air pressure for 30 minutes, turn off the heating, inject nitrogen gas to restore the cavity pressure to normal pressure, and continue to inject nitrogen gas to lower the cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com