Defect detection method based on polarization structured light imaging and improved Mask R-CNN

A structured light imaging and defect detection technology, applied in the field of image processing, can solve problems such as imperfect information, low precision and efficiency, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

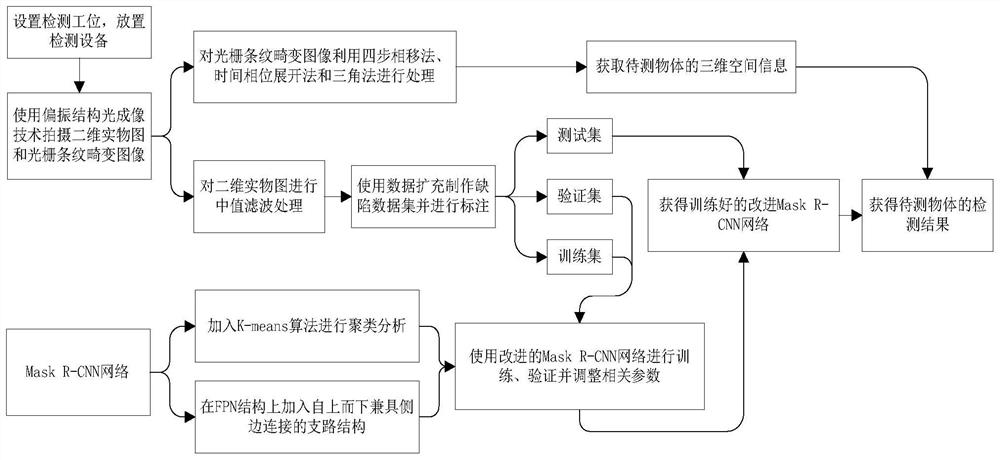

[0048] The defect detection method based on polarized structured light imaging and improved Mask R-CNN in this embodiment includes the following steps:

[0049] Step 1: Set up the detection station on the stage, and place a structured light optical projector and a laser light source at a predetermined angle above the detection station; place an industrial camera at the angle of reflected light, and place a polarizer in front of the industrial camera lens ; The predetermined angle is subject to suitability for industrial camera shooting.

[0050] Step 2: Place the object to be tested on the detection station, first turn on the laser light source to irradiate the surface of the object, and the reflected light enters the industrial camera after polarization proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com