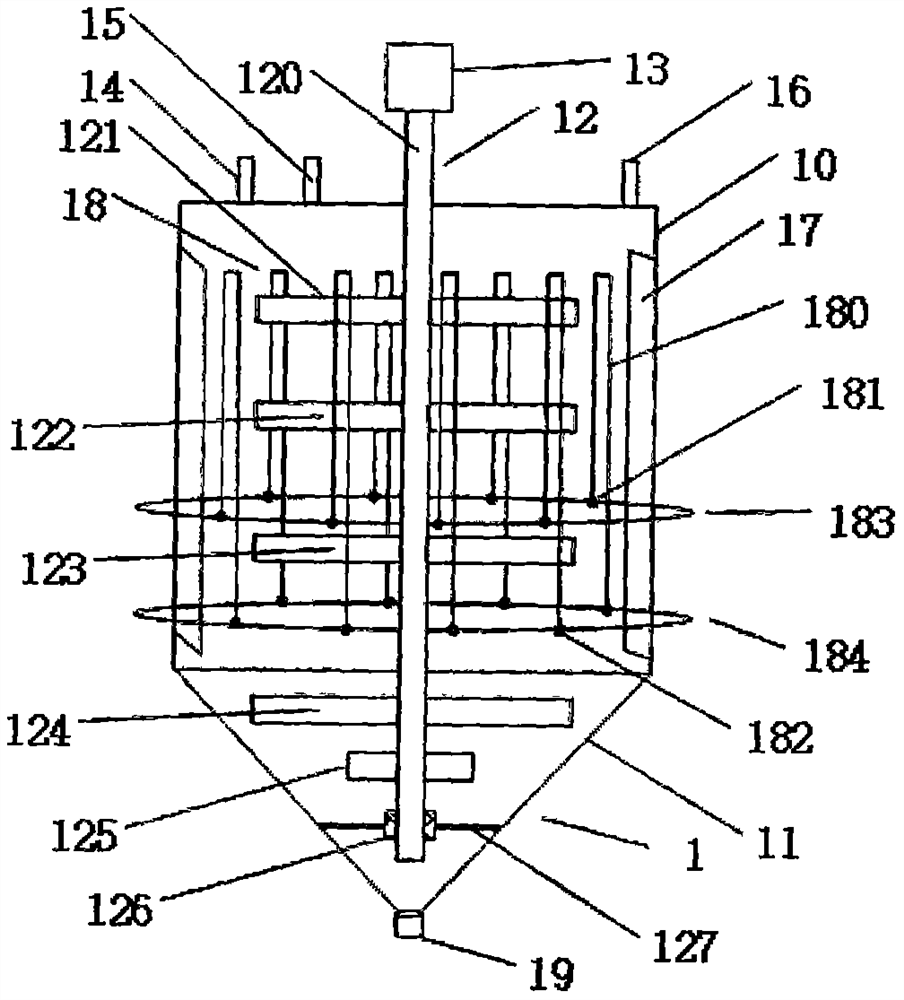

Device for saponifying and extracting ergosterol

An ergosterol and saponification technology, which is applied in organic chemistry, steroids, solid solvent extraction, etc., can solve the problems of long extraction process, high energy consumption, complex operation of saponification and extraction of ergosterol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

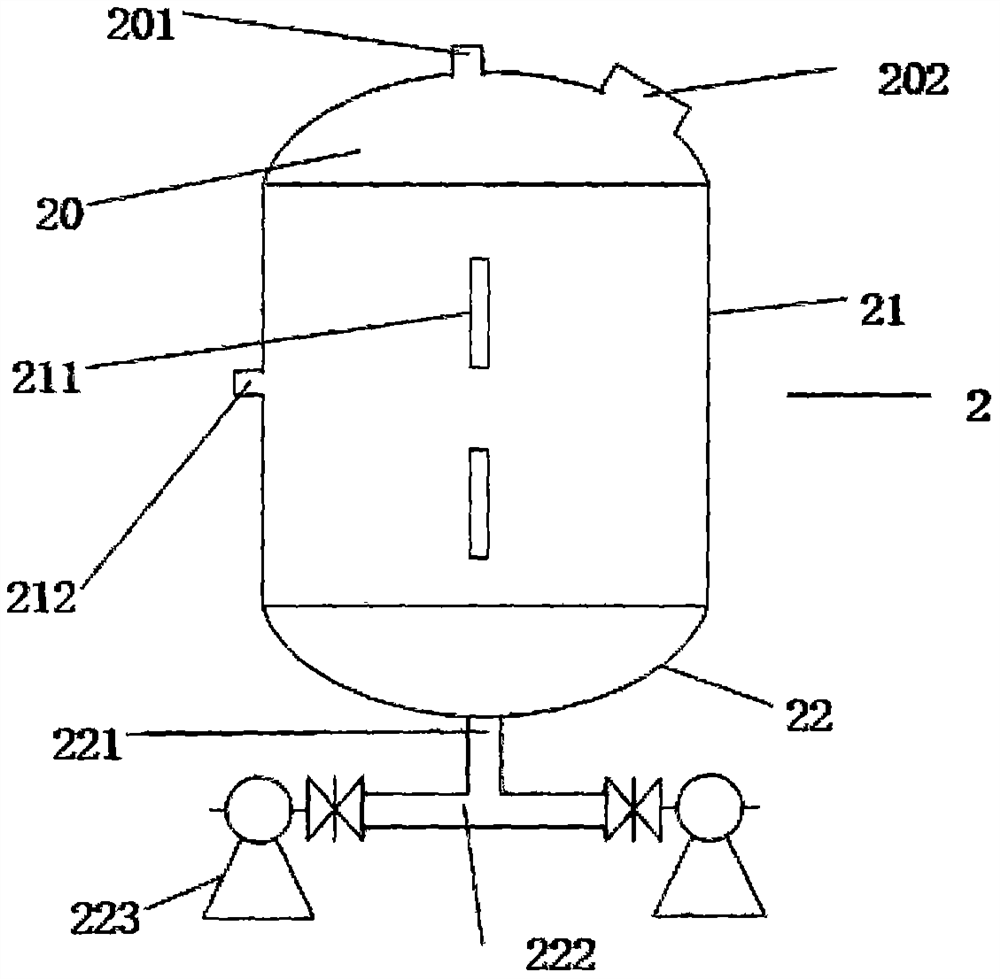

[0085] (1) Extraction: weigh 1kg of penicillin fermentation bacteria residue, add it to the extraction tank, add 1.2kg of methanol, maintain the temperature at 55°C by heating, add 70g of solid sodium hydroxide, stir for 6 hours, then add 1.2kg of petroleum ether, heat The temperature was maintained at 50°C and stirred for 3 hours.

[0086] (2) Filtration and phase separation: the material after the extraction reaction in step (1) is subjected to vacuum filtration, the filtrate is collected, the filtrate is pumped into the phase separation tank and left to stand for stratification, the upper layer light phase liquid is collected, and the lower layer solvent is recovered. At the same time, 0.5kg of filter cake was collected.

[0087] (3) decolorization and crystallization: add the upper layer liquid collected in step (2) filtration and phase separation into the decolorization tank with stirring device, maintain the temperature at 50 ° C, add 1 g of activated carbon, stir for 2 ...

Embodiment 2

[0090] (1) Extraction: weigh 1kg of penicillin fermentation bacteria residue, add it to the extraction tank, add 1.2kg of methanol, maintain the temperature at 55°C by heating, add 70g of solid sodium hydroxide, stir for 6 hours, then add 1.2kg of petroleum ether, heat The temperature was maintained at 50°C and stirred for 3 hours.

[0091] (2) Filtration and phase separation: the material after the extraction reaction in step (1) is subjected to vacuum filtration, the filtrate is collected, the filtrate is pumped into a phase separation tank and left to stand for stratification, the upper layer light phase liquid is collected, and the lower layer solvent is recovered. At the same time, 0.5kg of filter cake was collected.

[0092] (3) 2 extractions of filter cake: add the petroleum ether of 0.6kg in the extraction tank, then add the filter cake 0.5kg generated after step (2) filtration and phase separation; be warming up to 50 ° C, stir, maintain temperature and extract for 2 ...

Embodiment 3

[0097] (1) Extraction: Weigh 1 kg of penicillin fermentation bacteria residue, add it to the extraction tank, add 1.2 kg of chloroform, heat to maintain the temperature at 57° C., add 50 g of sodium hydroxide, and stir for 4 hours. 1.2 kg of n-heptane was added, the temperature was maintained at 50° C. by heating, and the mixture was stirred for 3 hours.

[0098] (2) Filtration and phase separation: the material after the extraction reaction in step (1) is subjected to vacuum filtration, the filtrate is collected, the filtrate is pumped into the phase separation tank and left to stand for stratification, the upper layer light phase liquid is collected, and the lower layer solvent is recovered.

[0099] (3) decolorization and crystallization: add the upper layer light phase liquid collected in step (2) filtration and phase separation into a decolorization tank with a stirring device, be warming up to 60 ° C, add 1 g of activated carbon, stir for 2 hours, and use vacuum extractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com