A method of crossing river and laying cables by using horizontal directional drilling technology

A technology for horizontal directional drilling and cable laying, which is applied to cable installation, cable installation in underground pipelines, and cable laying equipment. It can solve the problems of large manpower and material resources, long construction process, etc., and achieve low project cost and short construction period. , Effects that are difficult to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for crossing a river and laying a cable using horizontal directional drilling technology, the steps include:

[0042] S11: According to the location of the substation on both sides of the river and the geographical location on both sides of the river, determine the entry point and exit point of the horizontal directional drilling, the location of the well and the minimum navigable water level;

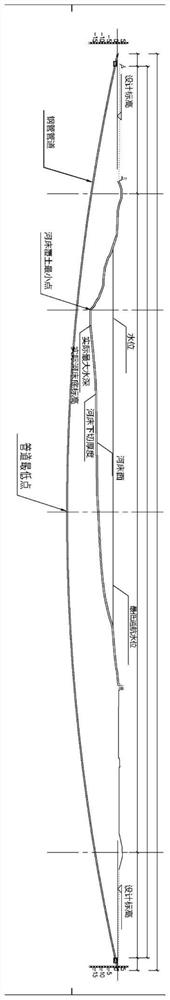

[0043] S12: according to figure 1 The lowest navigable water level shown, the water depth of the planned channel, figure 1 Calculate the top elevation of the first steel pipe based on the thickness of the riverbed undercut shown and the preset embedding depth;

[0044] S13: If figure 1 shown, according to figure 1 The actual riverbed bottom elevation shown, figure 1 Calculate the top elevation of the second steel pipe based on the indicated thickness of the undercut of the riverbed and the preset safe coverage thickness required for laying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com