Strong noise environment machine operation fault detection method and detection system

A technology for machine operation and fault detection. It is used in the testing of machines/structural components, instruments, measuring devices, etc. It can solve problems such as large noise impact, poor real-time detection, and information loss, and achieve strong noise suppression capability and noise suppression capability. Strong and stable output signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (1) MUSIC algorithm

[0078] It is well known that for a noise-contaminated signal, all practical signal detection methods are limited by the noise power or signal-to-noise ratio. Equation (1) shows that sampling is composed of multiple harmonics, but the actual signal harmonics are only a small part. If the actual signal does not represent a signal-significant feature of the sequence, it cannot be distinguished. All detection methods are limited by this characteristic, and they differ from other methods by improving the salient features in the frequency domain.

[0079] Suppose the sampling data is Y=X+W, and its autocorrelation matrix is R yy , whose eigenvalues can be decomposed into

[0080]

[0081] Among them, U 1 is the signal eigenvector, U 2 is the noise feature vector, ∑ 1 , ∑ 2 is a diagonal matrix. For Gaussian white noise, if its length is sufficient, its noise characteristic value is in (1)

[0082] and

[0083] Clearly, noise modula...

Embodiment 2

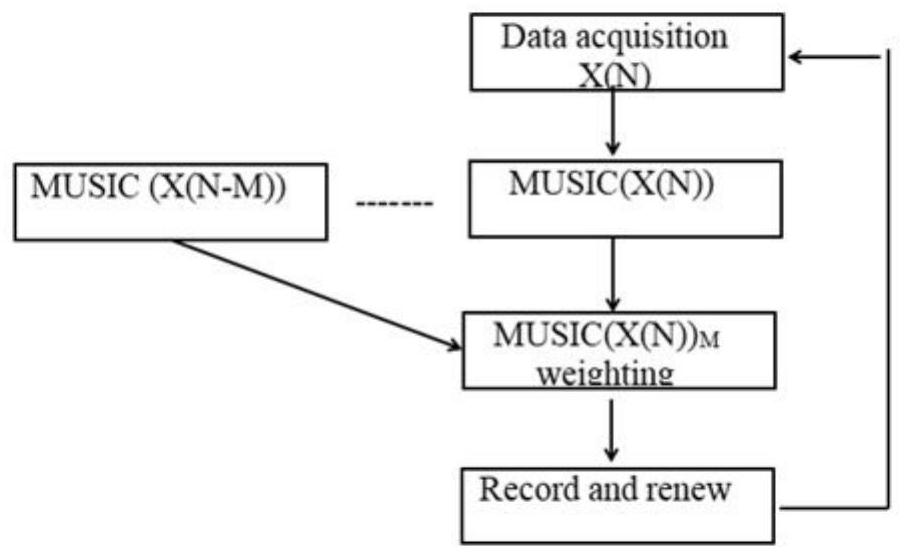

[0096] For mechanical vibration signals with noise interference, there are many fault detection methods, but most of them are not suitable for online real-time detection. The FFT algorithm has fast calculation speed and strong adaptability, and is the preferred algorithm for industrial online detection. However, when industrial machinery operates in a strong random interference environment, the stability of its FFT spectrum is poor. In order to solve the problem of fault detection in strong interference environment, a fault detection method based on MUSIC algorithm is designed.

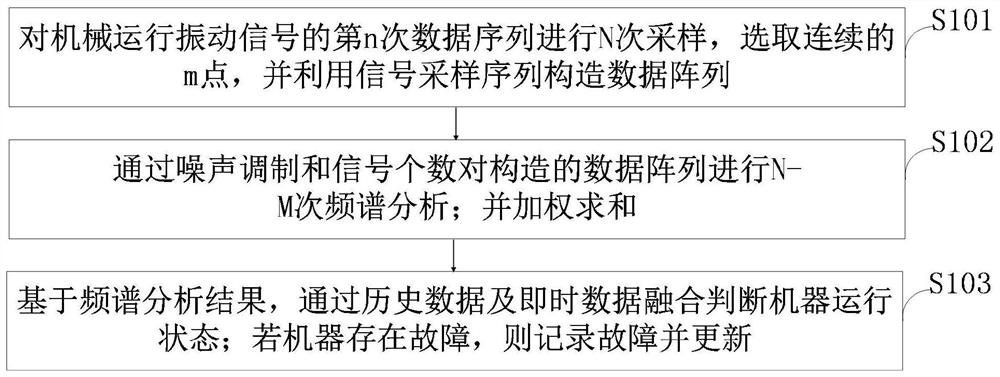

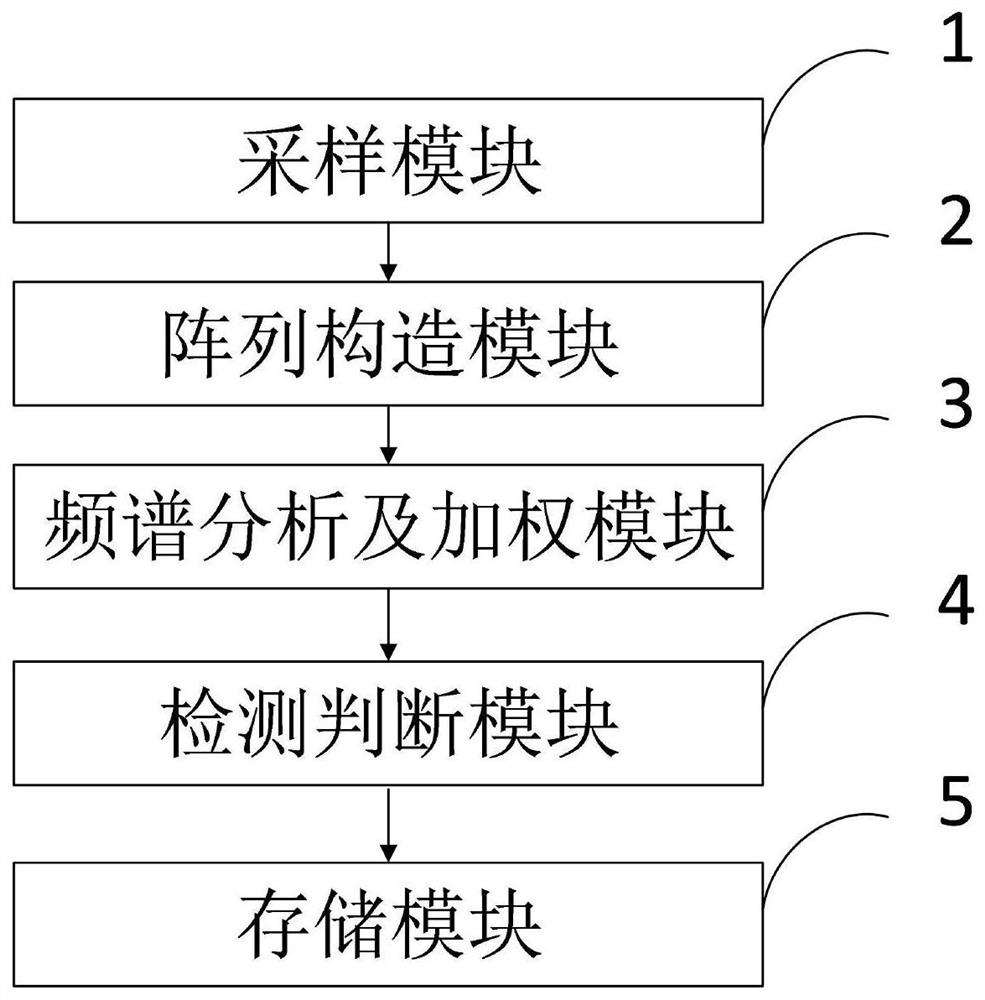

[0097] Step 1: Sampling the nth data sequence, selecting consecutive m points, and constructing a data array;

[0098] Step 2: Perform spectral analysis on the data array;

[0099] Step 3: Weighted summation;

[0100] Step 4: Log failure and update.

[0101] In this algorithm, the weight of MUSIC analysis coefficients not only plays the role of learning new frequency components, but also weakens t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com