Atmosphere box type sintering furnace for producing mobile phone back plate

A sintering furnace and atmosphere technology, applied in the field of ceramic sintering furnaces, can solve the problems of flue gas being harmful to human body, reducing production efficiency, affecting air quality, etc., and achieving the effects of preventing oxidation, reducing labor, and avoiding excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

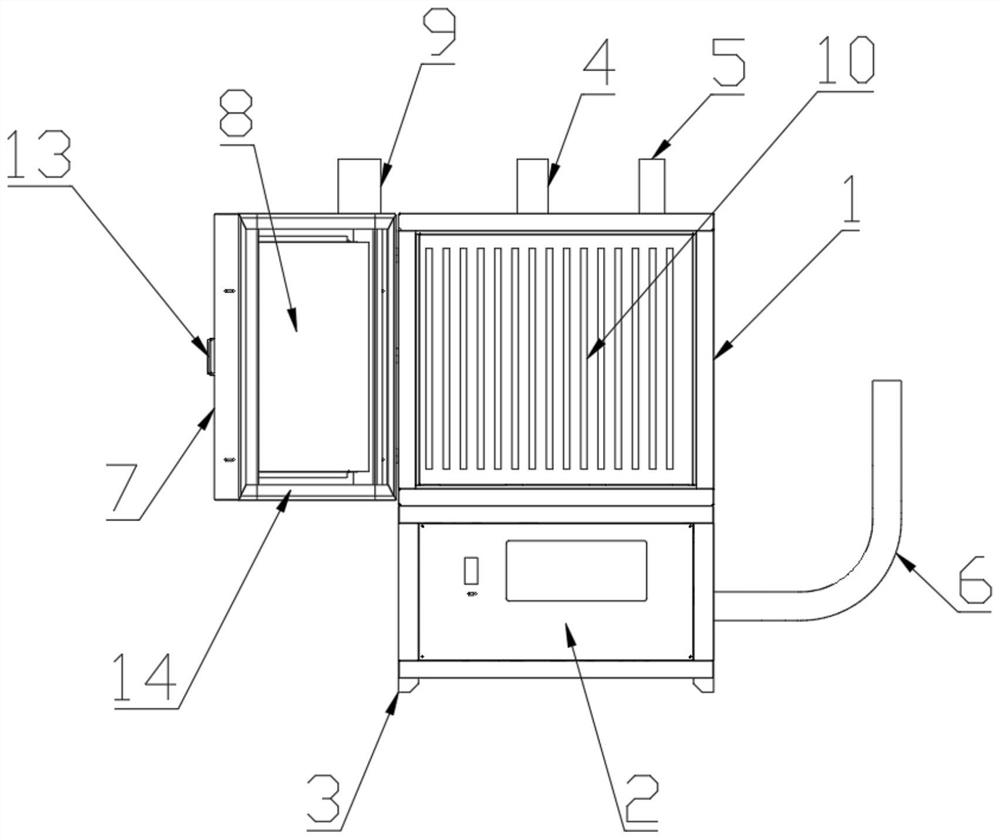

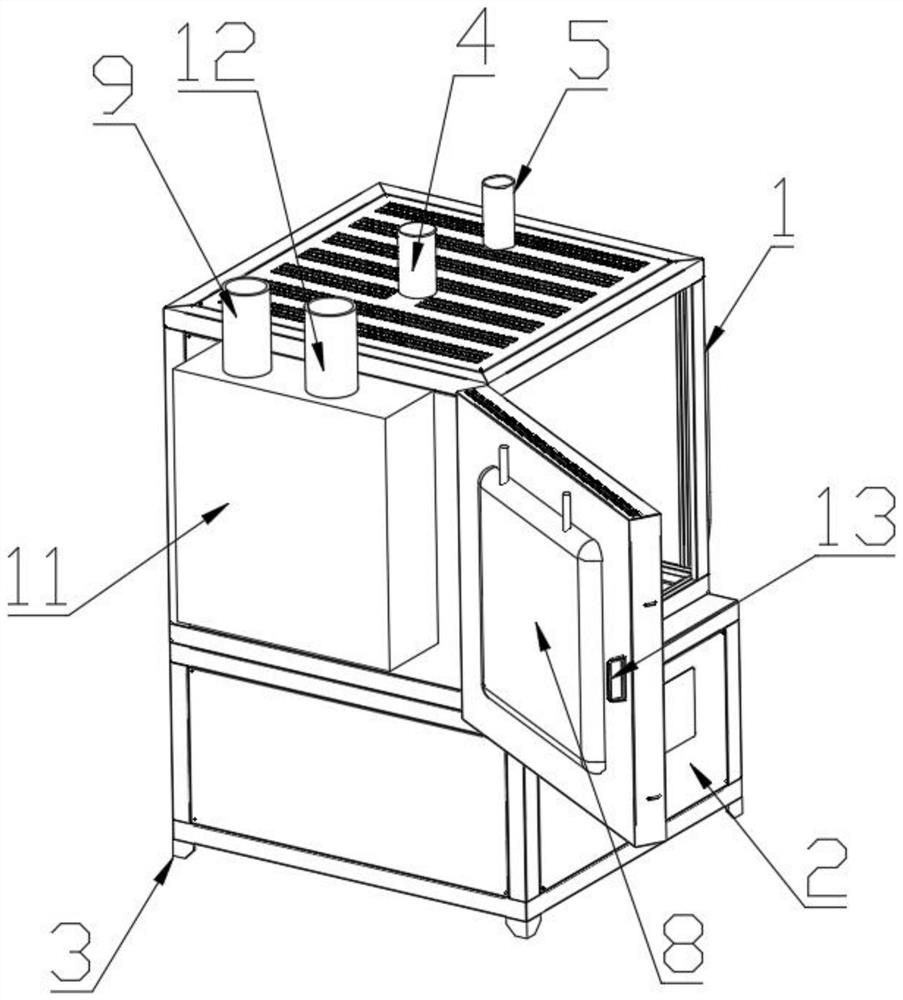

[0030] Such as figure 1 As shown, an atmosphere box-type sintering furnace for mobile phone backplane production, including

[0031] Furnace body 1, heating devices are arranged on the upper, left, right, lower, and rear sides of the inner side of the furnace body 1, the exterior of the furnace body 1 is metal, and the interior is provided with insulating materials, and a foot 3 is installed below the furnace body 1,

[0032] The filter box 2 is installed under the furnace body 1 and communicates with the interior of the furnace body 1 through a plurality of uniformly arranged holes. A degreasing pipe 6 is installed on the side of the filter box 2, and the degreasing pipe 6 is connected to the fan.

[0033] Air extraction port 4, said air extraction port 4 communicates with furnace body 1, can vacuumize furnace body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com