A support chassis for a multifunctional numerical control machine tool

A CNC machine tool, multi-functional technology, applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., can solve the problems of reduced production efficiency, low flexibility of supporting chassis clamping, unfavorable fixing of CNC machine tools, etc., to achieve easy control, Ensure long-term effective operation and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

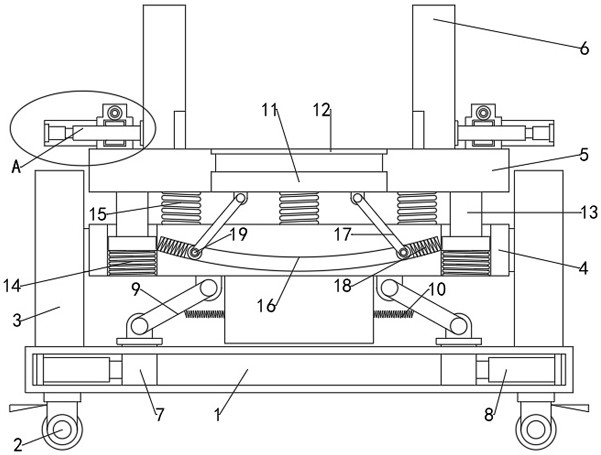

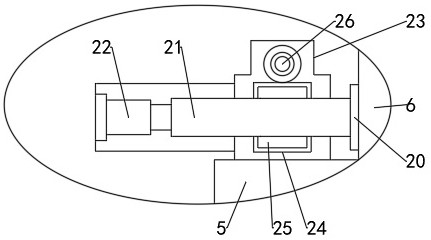

[0020] see Figure 1-4 , a support chassis for a multifunctional numerically controlled machine tool, comprising a base 1, a lift platform 4 is movably installed on the upper end of the base 1, a support seat 5 is mounted on the lift platform 4, and a limit mechanism is arranged on the support seat 5; The limit mechanism includes a limit plate 6, two vertical limit plates 6 are arranged at intervals on the support seat 5, the limit plate 6 and the support seat 5 are slidably installed, and a pressure sensor is installed on one side of the limit plate 6, One side of the limiting plate 6 facing away from the pressure sensor is equidistantly arranged with several drive mechanisms; the drive mechanism includes a drive chamber 23, which is fixed on the support seat 5, and a horizontal screw mandrel 21 is assembled in the drive chamber 23. One end of the screw rod 21 extends to the outside of the driving chamber 23 and is fixedly connected with the limit plate 6 through the connecti...

Embodiment 2

[0029] In order to improve the stability of the support chassis when it is placed and avoid sliding during use, this embodiment is improved on the basis of Embodiment 1. The improvement is: the bottom surface of the positioning block 30 is provided with uniform anti-skid lines , which is used to increase the frictional force between the positioning block 30 and the placement surface, so as to prevent the support chassis from slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com