Continuous beam pipeline force rib friction loss testing method based on karst cave underground river environment

A test method and cave technology, applied in force/torque/work measuring instruments, force sensors in the holes of stressed structures, tunnels, etc. Stability and reliability, the effect of improving backfill and stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

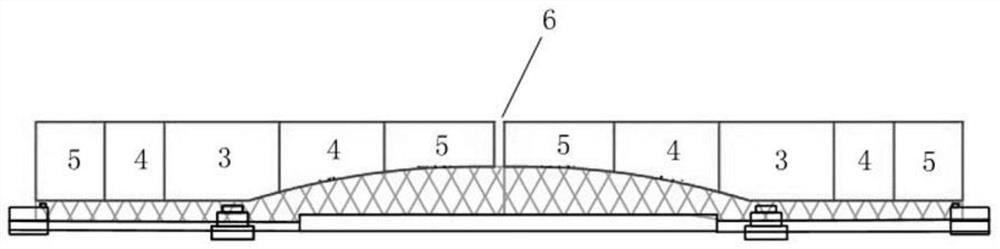

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

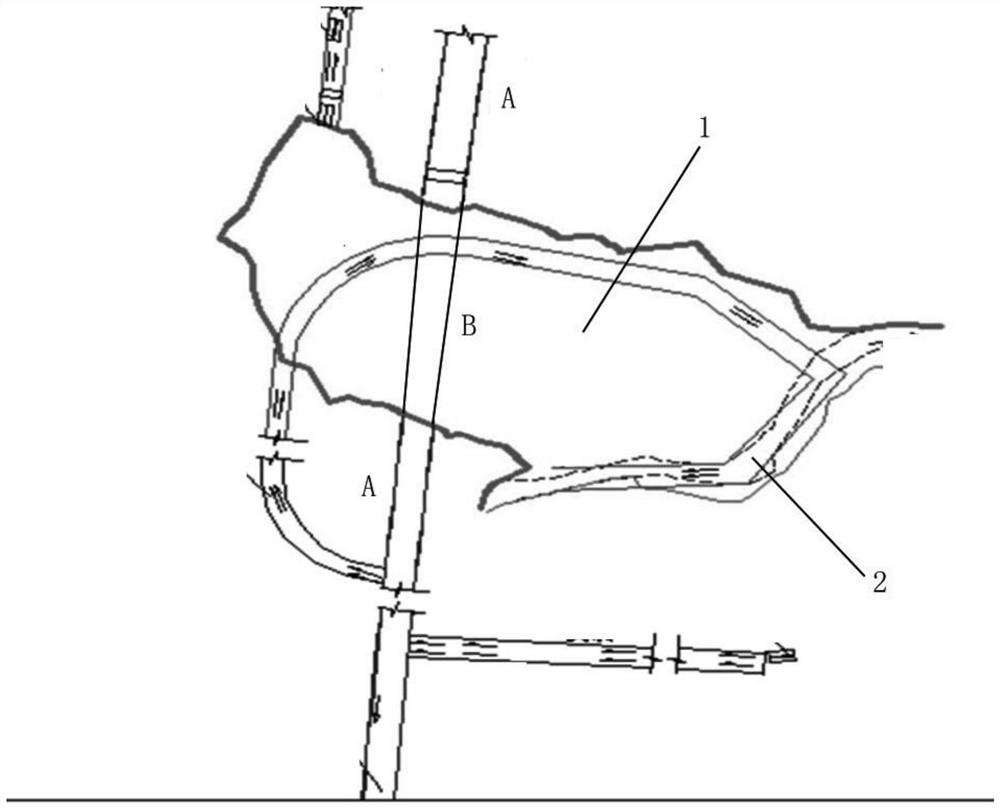

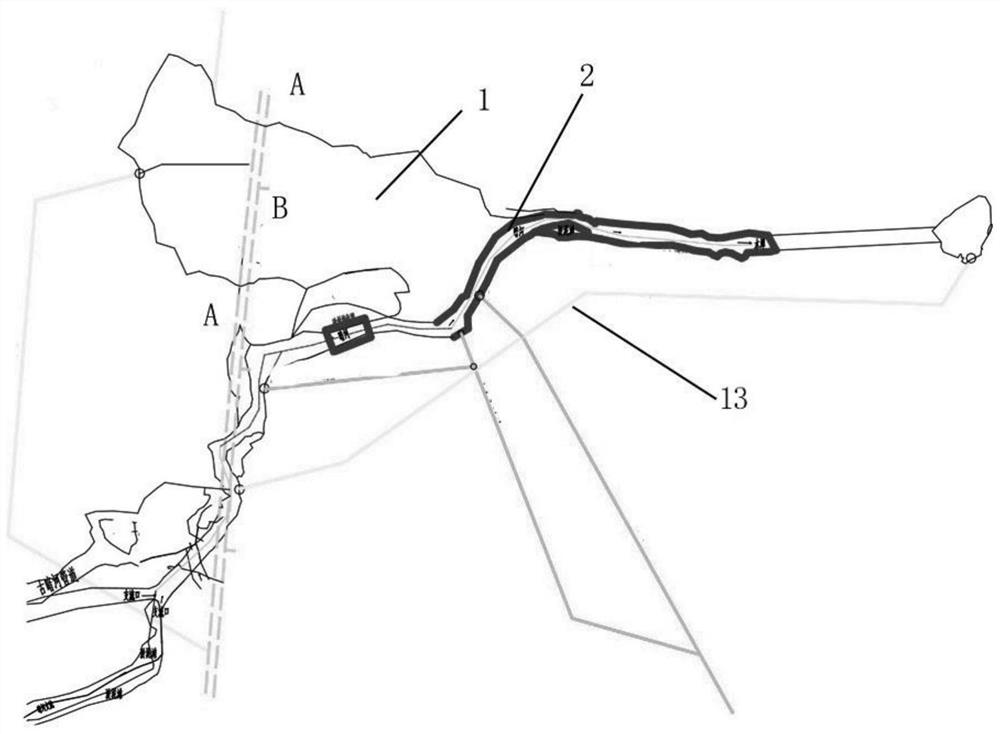

[0033] Such as Figure 1 to Figure 4 As shown, the present invention is based on a kind of embodiment of the method for testing the friction loss of continuous beam pipeline force tendons in the karst cave underground river environment. The environment includes a karst cave 1 and an underground river 2 at the bottom of the karst cave 1. The tunnel is section A of the tunnel, and the tunnel passing through the karst cave 1 is section B of the tunnel; the construction method includes the following steps:

[0034] S1: Excavate section A of the tunnel to penetrate the karst cave 1;

[0035] S2: Divert the underground river 2 so that the underground river 2 does not flow through the cave 1;

[0036] S3: backfill the karst cave 1 until it is backfilled to the foundation surface of the tunnel;

[0037] S4: Carry out protective treatment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com