Novel substitute material of seamless steel tubes for oil cylinders

A technology of seamless steel pipes and new materials, applied in the field of seamless steel pipes, can solve the problems of reducing fatigue life, shortening service life, reducing the strength of seamless steel pipes, etc., so as to reduce the tendency of weldable heat-sensitive cracks and improve safe service life. , The effect of prolonging the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

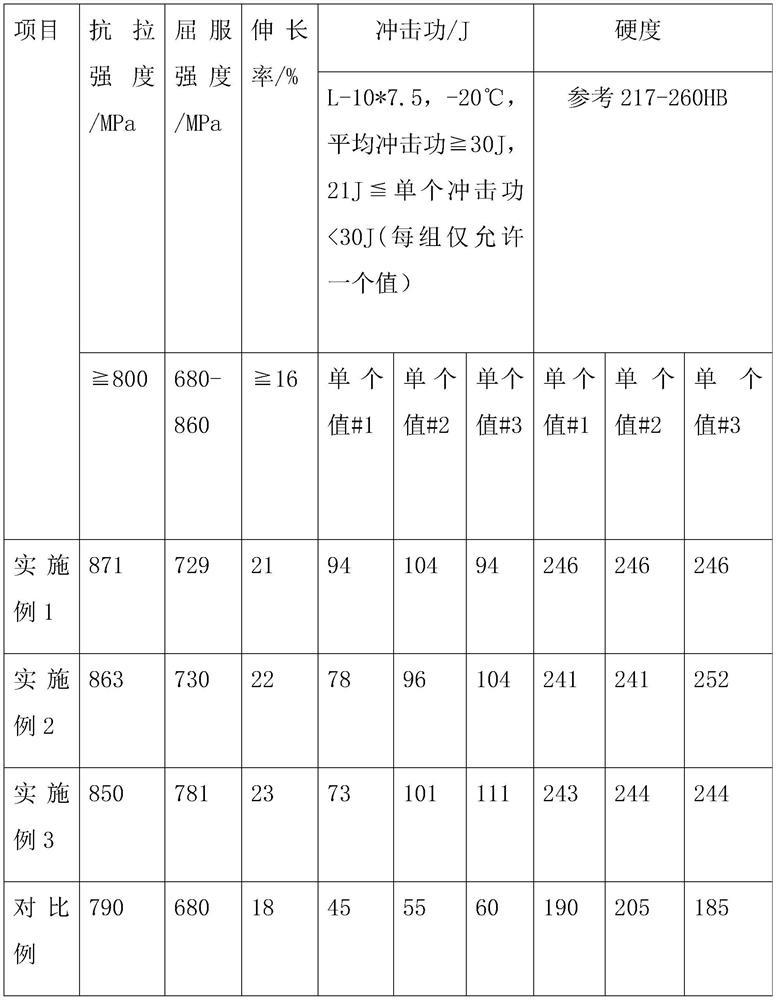

[0024] A new alternative material for seamless steel pipes for oil cylinders, the formula includes: C, Si, Mn, P, S, Al, Cr, Ni, Mo, Ti, V, Cu, Nb and Fe; the mass percentages of each component are respectively Yes: 0.15-0.19% C, 0.3-0.45% Si, 1.35-1.6% Mn, P≦0.025%, S≦0.015%, Cr≦0.25%, Ni≦0.25%, Mo≦0.1%, Ti≦0.1%, V≦0.1%, Cu≦0.2%, TAl≦0.025% and Nb≦0.1%, the rest is Fe, of which Si, Mn, Al, Cr, Ni, Mo, Ti, V, Cu and Nb all contain such metals Elements exist in the form of pig iron, and Fe is a high-quality scrap iron with less rust on the surface, no impurities, and a suitable size.

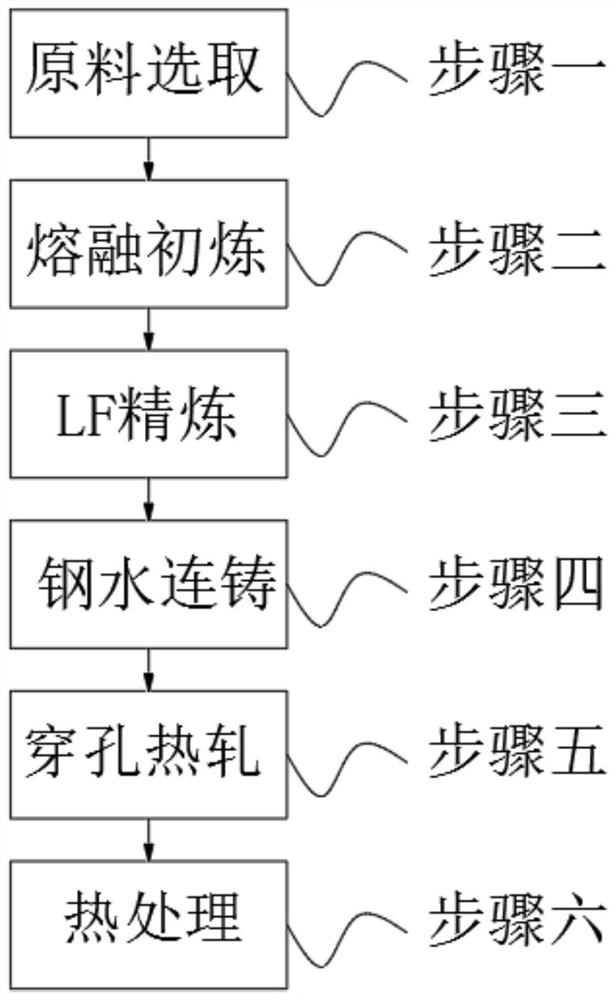

[0025] According to the above-mentioned technical scheme, a method for preparing a new substitute material for a seamless steel pipe for an oil tank comprises step 1, raw material selection; step 2, melting primary refining; step 3, LF refining; step 4, continuous casting of molten steel; step 5, Piercing hot rolling; Step 6, heat treatment;

[0026] Wherein in the above-mentioned step 1, high-...

Embodiment 2

[0033] A new alternative material for seamless steel pipes for oil cylinders, the formula includes: C, Si, Mn, P, S, Al, Cr, Ni, Mo, Ti, V, Cu, Nb and Fe; the mass percentages of each component are respectively Yes: 0.15-0.19% C, 0.3-0.45% Si, 1.35-1.6% Mn, P≦0.025%, S≦0.015%, Cr≦0.25%, Ni≦0.25%, Mo≦0.1%, Ti≦0.1%, V≦0.1%, Cu≦0.2%, TAl≦0.025% and Nb≦0.1%, the rest is Fe, of which Si, Mn, Al, Cr, Ni, Mo, Ti, V, Cu and Nb all contain such metals Elements exist in the form of pig iron, and Fe is a high-quality scrap iron with less rust on the surface, no impurities, and a suitable size.

[0034] According to the above-mentioned technical scheme, a method for preparing a new substitute material for a seamless steel pipe for an oil tank comprises step 1, raw material selection; step 2, melting primary refining; step 3, LF refining; step 4, continuous casting of molten steel; step 5, Piercing hot rolling; Step 6, heat treatment;

[0035] Wherein in the above-mentioned step 1, high-...

Embodiment 3

[0042] A new alternative material for seamless steel pipes for oil cylinders, the formula includes: C, Si, Mn, P, S, Al, Cr, Ni, Mo, Ti, V, Cu, Nb and Fe; the mass percentages of each component are respectively Yes: 0.15-0.19% C, 0.3-0.45% Si, 1.35-1.6% Mn, P≦0.025%, S≦0.015%, Cr≦0.25%, Ni≦0.25%, Mo≦0.1%, Ti≦0.1%, V≦0.1%, Cu≦0.2%, TAl≦0.025% and Nb≦0.1%, the rest is Fe, of which Si, Mn, Al, Cr, Ni, Mo, Ti, V, Cu and Nb all contain such metals Elements exist in the form of pig iron, and Fe is a high-quality scrap iron with less rust on the surface, no impurities, and a suitable size.

[0043] According to the above-mentioned technical scheme, a method for preparing a new substitute material for a seamless steel pipe for an oil tank comprises step 1, raw material selection; step 2, melting primary refining; step 3, LF refining; step 4, continuous casting of molten steel; step 5, Piercing hot rolling; Step 6, heat treatment;

[0044] Wherein in the above-mentioned step 1, high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com