High-efficiency ceramic slurry preparation process

A preparation process and high-efficiency technology, used in clay products, applications, household appliances, etc., can solve the problems of high performance requirements of slurry, save ball milling time, avoid slurry scrap, and have good plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

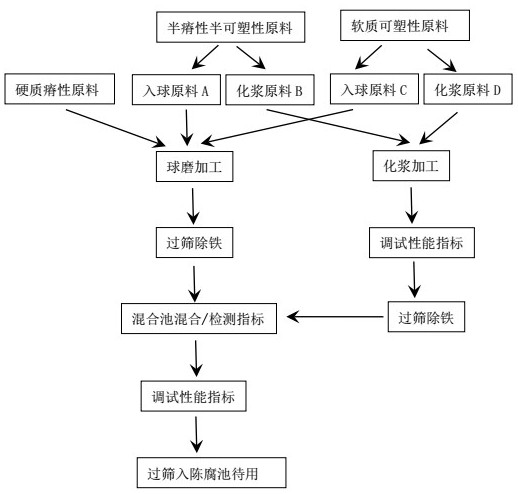

[0026] Attached below figure 1 And specific embodiments further illustrate the technical solution of the present invention.

[0027] A high-efficiency ceramic slurry preparation process, comprising the following steps:

[0028] (1) Ceramic mud raw materials are classified into: hard barren raw materials, semi-barren semi-plastic raw materials and soft plastic raw materials;

[0029] Semi-infertile and semi-plastic raw materials include balling raw material A and pulping raw material B; soft plastic raw materials include balling raw material C and pulping raw material D;

[0030] Putting the hard barren raw material, the ball-in raw material A and the ball-in raw material C together into a ball mill for ball milling to obtain ball mill mud;

[0031] (2) Put the pulping raw material B and the pulping raw material D into the pulping tank and add water to stir to obtain the pulping slurry;

[0032] (3) Transfer the ball mill slurry and chemical slurry to the mixing tank, and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com