Optical fiber preform rod tail wire drawing control system and method

An optical fiber preform and rod tail drawing technology, which is applied in photovoltaic modules, photovoltaic power generation, manufacturing tools, etc., can solve problems such as affecting the qualified rate of products, unqualified production parameters, and large diameter of optical fiber preforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

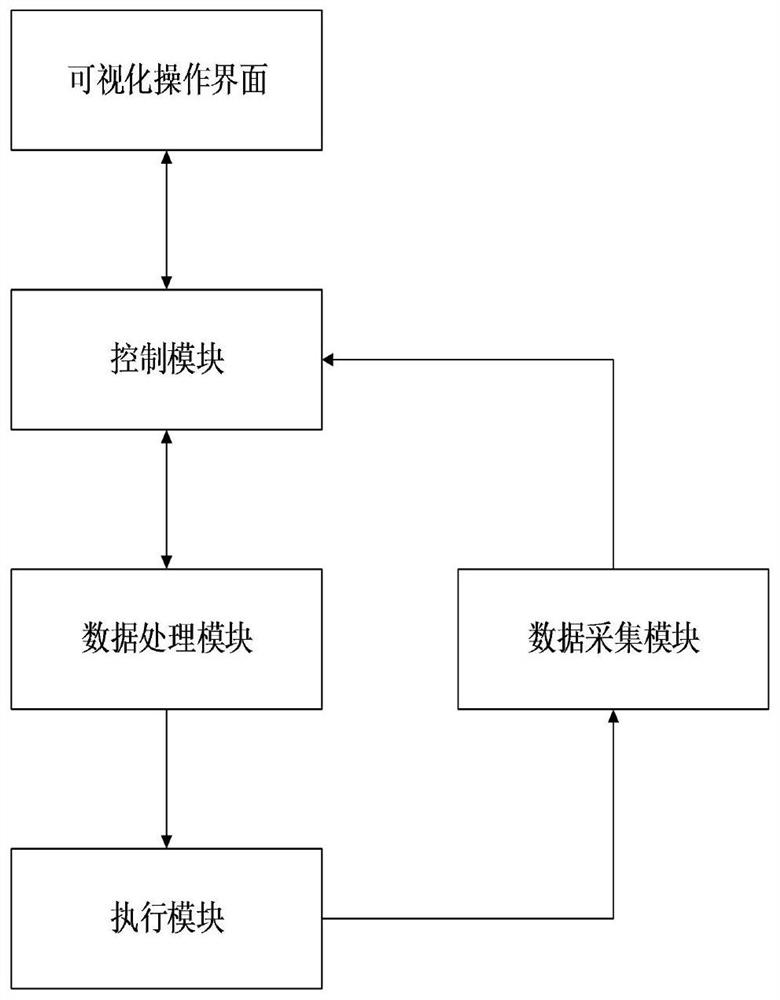

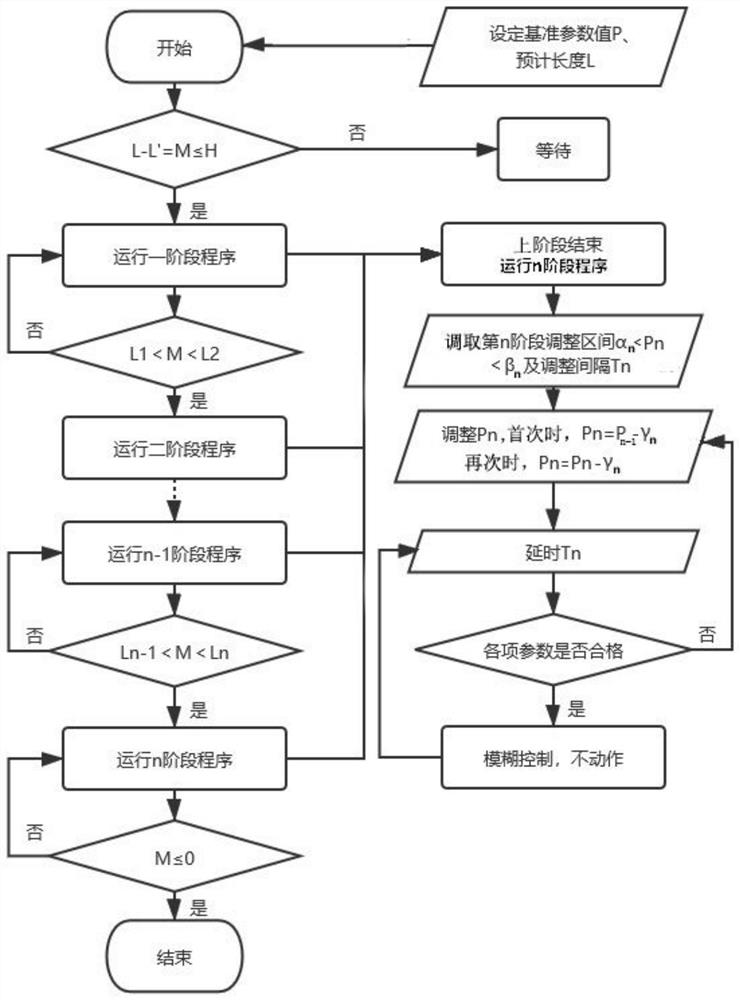

[0075] The invention discloses an optical fiber prefabricated rod tail drawing control system, which includes a visual operation interface for setting and viewing parameters connected in sequence, a control module for controlling the execution module to draw according to the control parameters, and a control module for controlling the parameters. A data processing module for adjustment and an execution module capable of wire drawing, and a data acquisition module capable of collecting optical fiber specification parameters and production line status in real time and transmitting them to the control module is connected in communication between the execution module and the control module. With the above optimized design, during the wire drawing process, all parameters are visualized, which is convenient for personnel to check; the degree of automation is high, which reduces manual participation and improves product consistency.

[0076] Specifically, the parameters to be set and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com