Method for degrading organic wastewater

A technology for organic wastewater and solutions, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high energy consumption and cost, sensory pollution, wastewater volume limitation, etc., and achieve good physical Effects of chemical stability, reduction of evaporation treatment volume, and reduction of treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

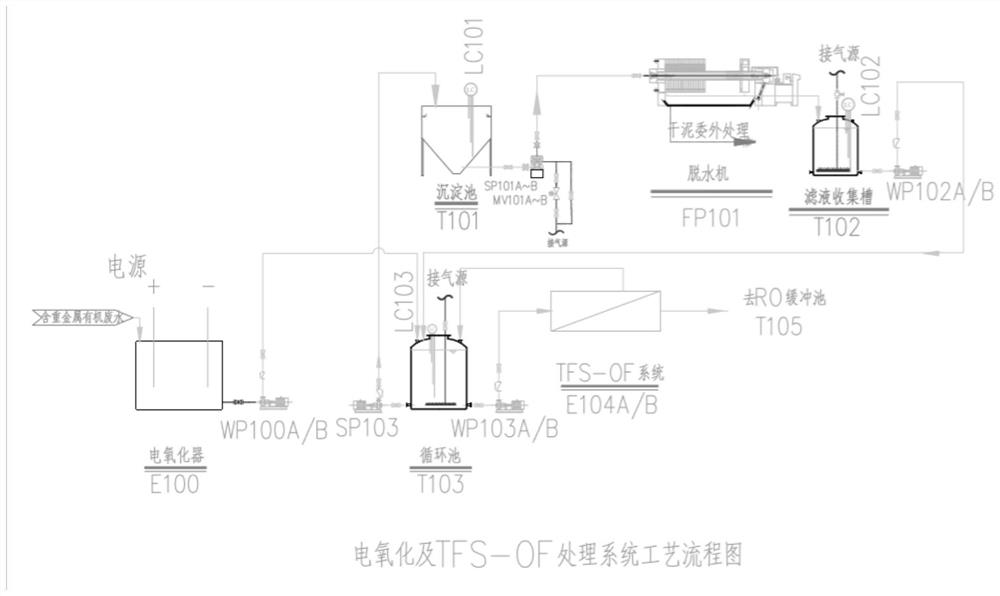

[0032] An embodiment of a method for degrading organic wastewater according to the present invention, the schematic flow chart of the method for degrading organic wastewater described in this embodiment is as follows figure 1 As shown, the specific steps are:

[0033] (1) The industrial heavy metal organic wastewater is sent into a high-performance electro-oxidizer using an inlet pump to perform electro-oxidation pretreatment for 3 hours at 30° C.; the high-performance electro-oxidizer uses a boron-doped diamond film composite cathode electrode and an anode electrode plate. The oxidized electrode area is 25cm 2 , the electrooxidation current is 0.75A, and the voltage is 2.6V;

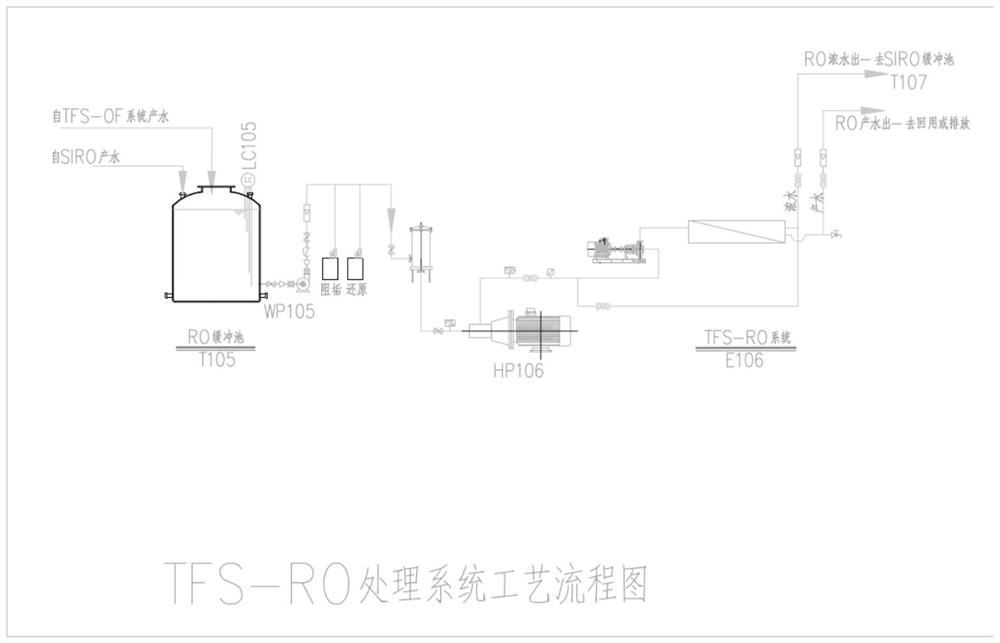

[0034] (2) Adjust the organic wastewater after electro-oxidation pretreatment in step (1) to pH=7 and then send it to the membrane concentration system for filtration and concentration. The high-performance electro-oxidizer and membrane concentration system process schematic diagram is as follows Fig...

Embodiment 2

[0037] A kind of embodiment of the method for degrading organic waste water of the present invention, the method for degrading organic waste water described in the present embodiment, concrete steps are:

[0038] (1) The industrial heavy metal organic wastewater is sent into a high-performance electro-oxidizer using an inlet pump to perform electro-oxidation pretreatment at 35° C. for 2.5 hours; the high-performance electro-oxidizer uses a boron-doped diamond film composite cathode electrode and an anode electrode plate, The electrode area of electro-oxidation is 25cm 2 , the electrooxidation current is 0.875A, and the voltage is 2.4V;

[0039] (2) The organic wastewater after the electro-oxidation pretreatment in step (1) is adjusted to pH=7 and then sent to the membrane concentration system for filtration and concentration; the filter membrane pore size used in the TFS-OF system in the membrane concentration system is 0.05 μm; the flow velocity of organic wastewater in th...

Embodiment 3

[0042] A kind of embodiment of the method for degrading organic waste water of the present invention, the method for degrading organic waste water described in the present embodiment, concrete steps are:

[0043] (1) The industrial heavy metal organic wastewater is sent into a high-performance electro-oxidizer using an inlet pump to perform electro-oxidation pretreatment for 3.5 hours at 25° C.; the high-performance electro-oxidizer uses a boron-doped diamond film composite cathode electrode and an anode electrode plate, The electrode area of electro-oxidation is 25cm 2 , the electrooxidation current is 0.75A, and the voltage is 2.8V;

[0044] (2) The organic wastewater after the electro-oxidation pretreatment in step (1) is adjusted to pH=7 and then sent to the membrane concentration system for filtration and concentration; the filter membrane pore size used in the TFS-OF system in the membrane concentration system is 0.05 μm; the flow velocity of organic wastewater in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com