Plastic foaming and fluidized drying integrated system

A fluidized drying, integrated technology, applied in the field of plastic product production, can solve problems such as steam entry, reduce waste, reduce costs, and facilitate promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

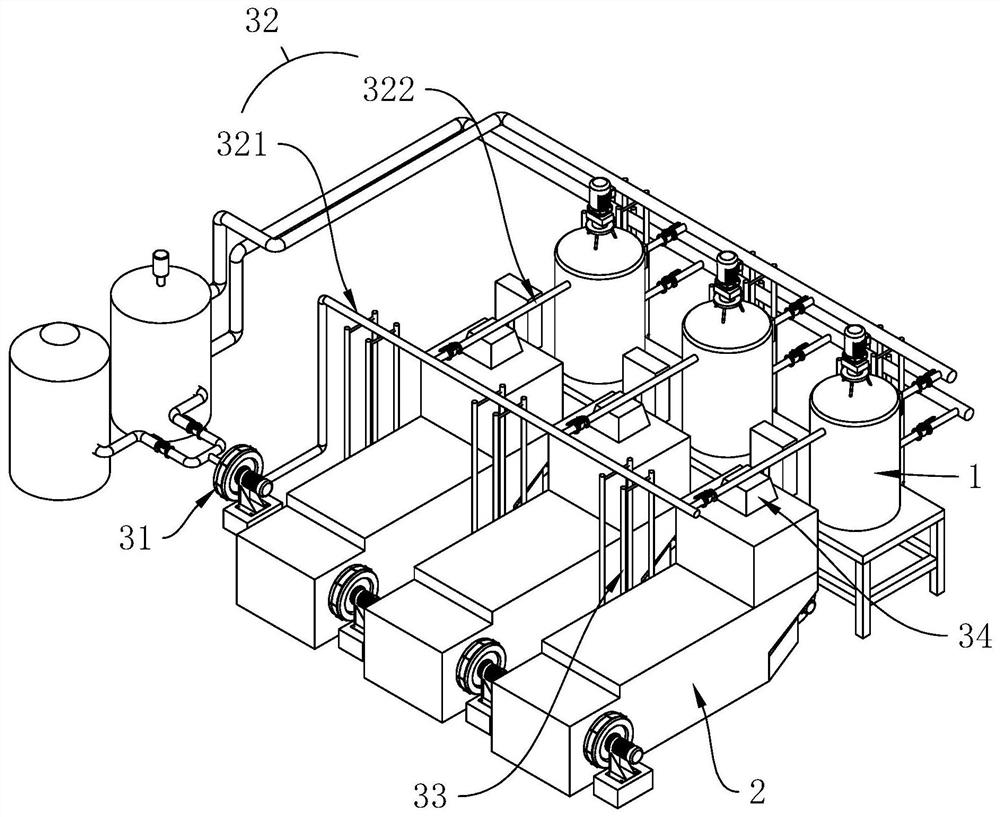

[0035] The following is attached Figure 1-5 The application is described in further detail.

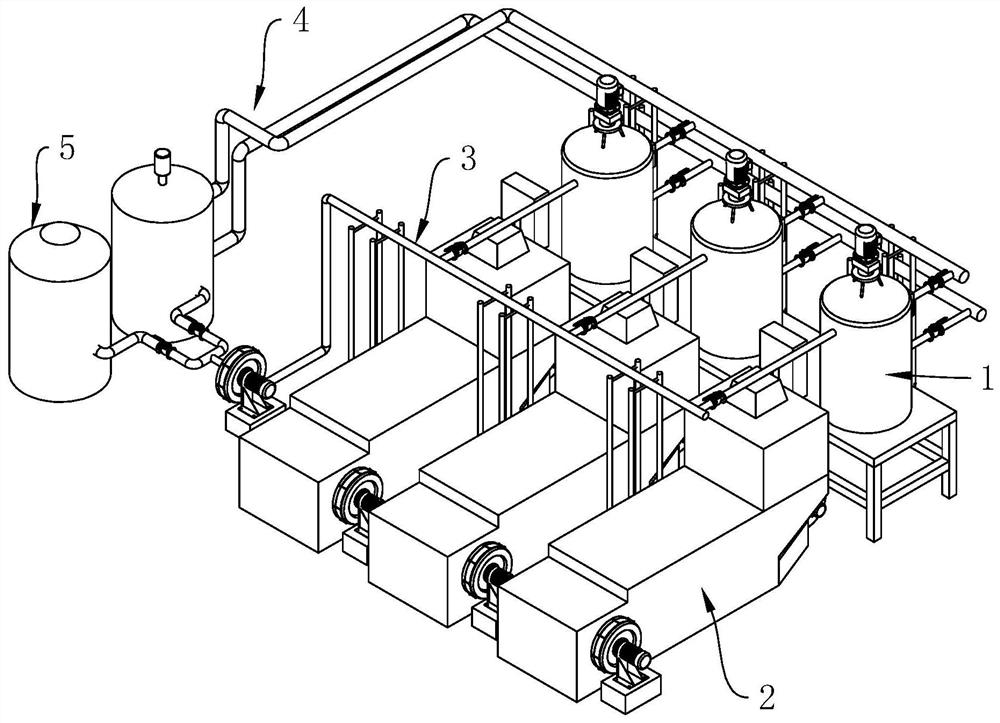

[0036] The embodiment of the present application discloses an integrated plastic foaming fluidized drying system. refer to figure 1 , the system includes a foaming machine 1, a fluidized drying bed 2, a gas-material separation component 3, a gas-liquid separation component 4 and an exhaust gas treatment device 5, the foaming machine 1 is used for pre-foaming raw materials, and the fluidized drying bed 2 It is used to fluidize and dry the foamed plastic particles after foaming. The steam separation component 3 is used to separate the foamed plastic particles from the steam. The gas-liquid separation component 4 is used to separate the water vapor and air in the steam. The tail gas treatment equipment 5 It is used to treat the waste gas generated when the fluidized drying bed 2 works.

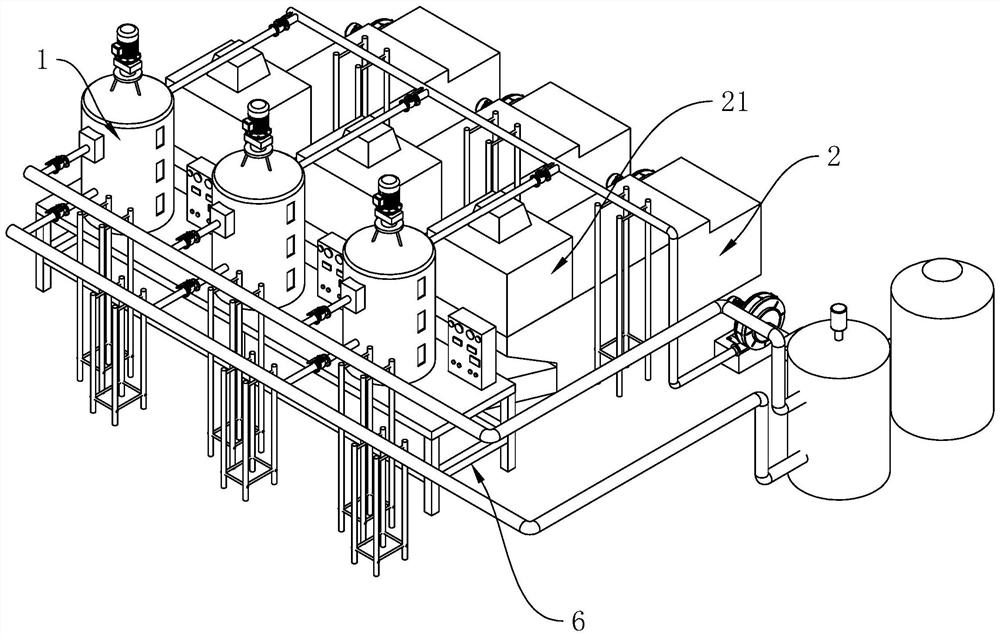

[0037] refer to figure 2 , the foaming machine 1 and the fluidized drying bed 2 are all provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com