Surface machining treatment device for motor shaft of soybean milk machine and shaft machining technology

A surface processing and processing device technology, applied in electromechanical devices, positioning devices, metal processing, etc., can solve problems such as low processing efficiency, and achieve the effect of improving stability and saving installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

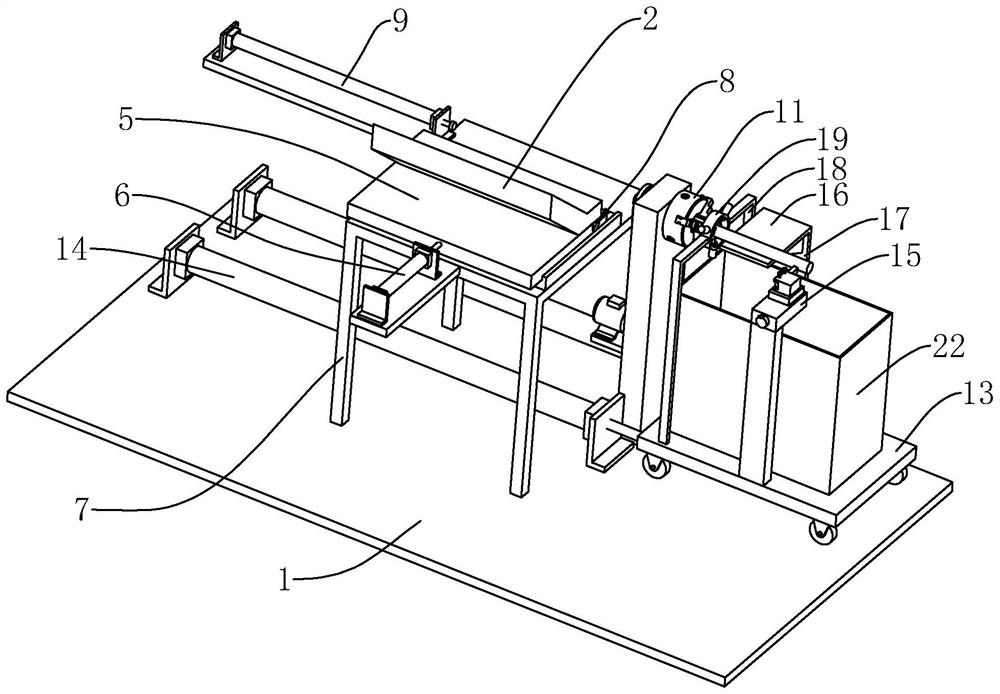

[0066] The following is attached Figure 1-8 The application is described in further detail.

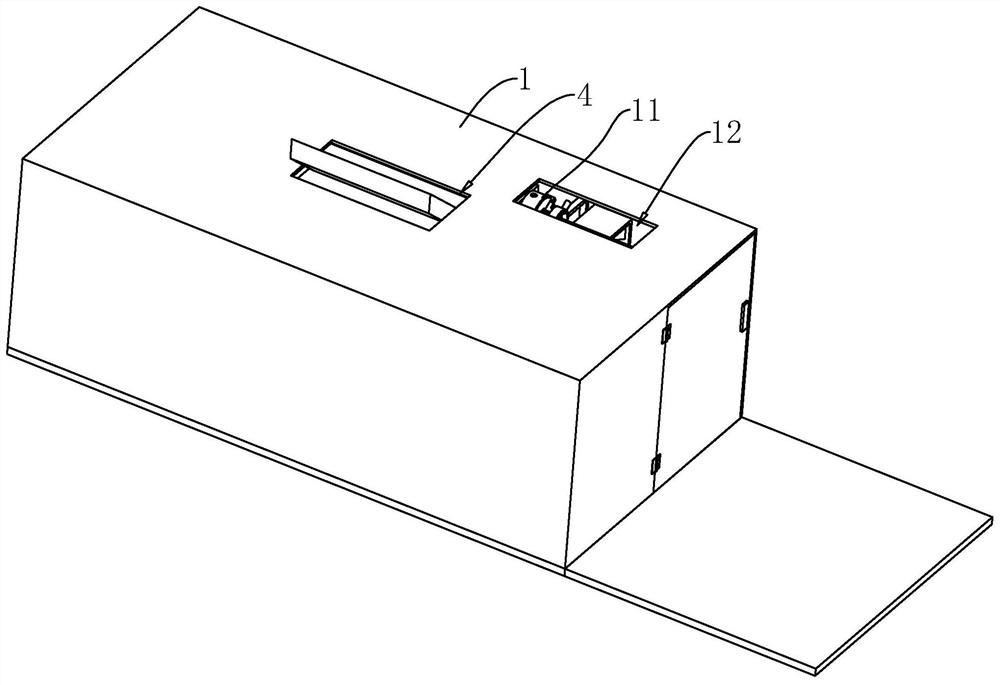

[0067] The embodiment of the present application discloses a surface processing device for a motor shaft of a soybean milk maker. refer to figure 1 , The surface processing device includes a bar transportation mechanism, a clamping mechanism, a cutting mechanism and a temporary storage mechanism for temporarily storing the cut bars arranged on the chassis 1.

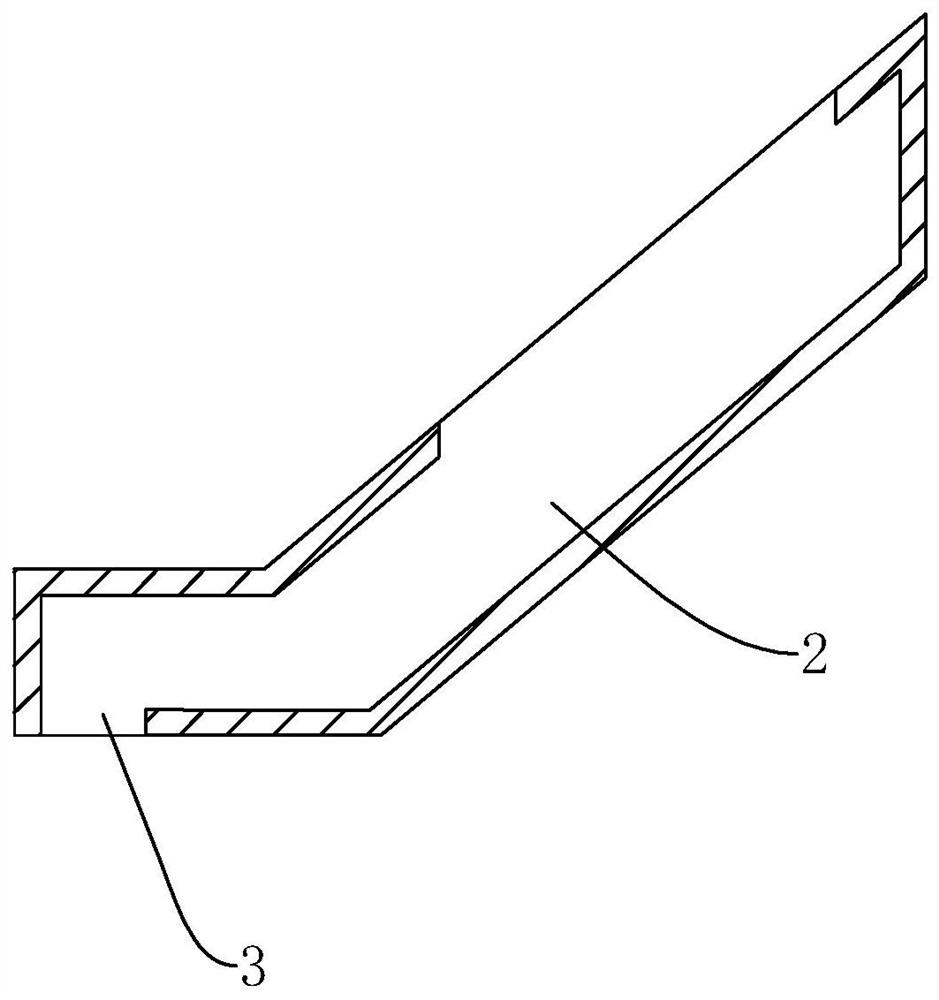

[0068] refer to figure 1 , figure 2 , the bar transport mechanism includes a feeding box 2 fixedly connected to the upper surface of the cabinet 1, the bottom of the feeding box 2 is set to be formed by a horizontal plane and an inclined surface, and the box opening of the feeding box 2 is arranged on the inclined surface side, and the arrangement height of the inclined surface is higher than that of the horizontal plane, wherein the position of the horizontal plane is the horizontal part, and the position of the inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com