A method of producing an additive manufactured object

An additive manufacturing and object technology, applied in the field of additively manufactured objects, can solve the problems of difficulty, time-consuming, and difficulty in ensuring the dimensional tolerance and accuracy repeatability of additively manufactured objects, and achieves easy disposal and low labor requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

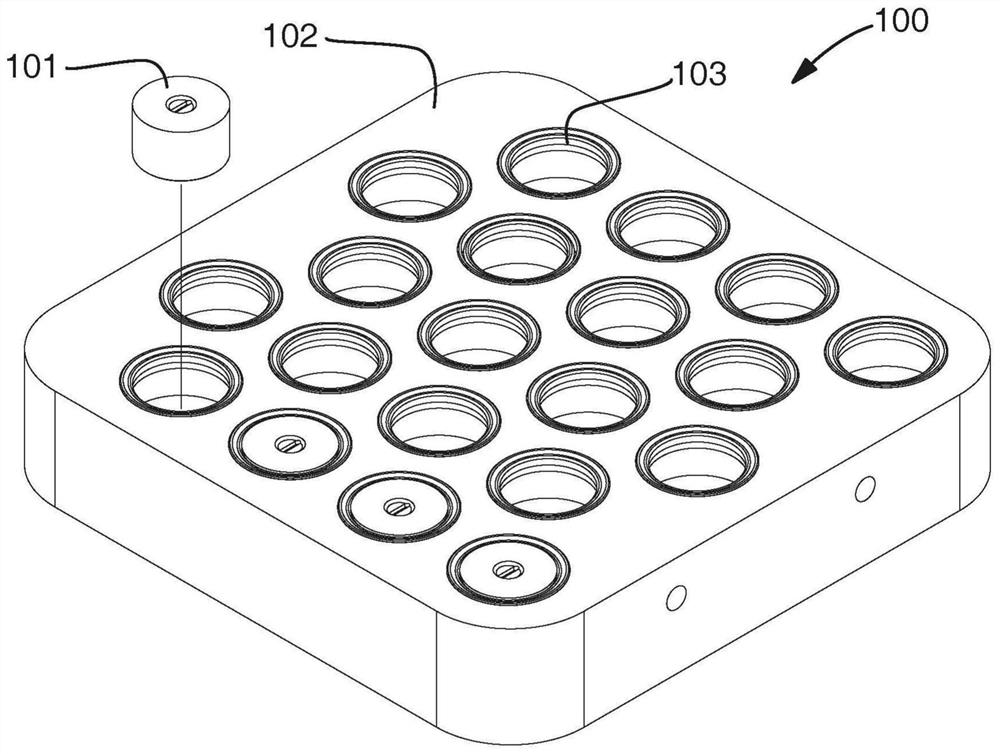

[0055] figure 1 An embodiment of a substrate device system 100 comprising a substrate device 101 and a support member 102 is schematically illustrated. In this embodiment, the support member 102 is in the form of a solid plate provided with apertures 103 .

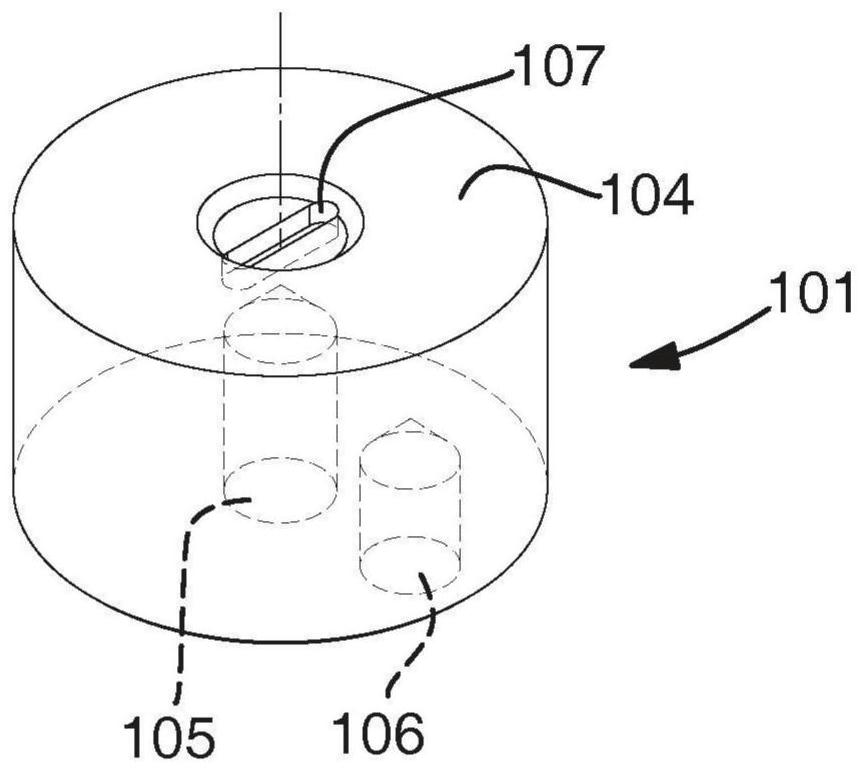

[0056] figure 2 An embodiment of a substrate device 101 is shown having a build surface 104 and being generally cylindrical in shape. The substrate device also has alignment members 105, 106 in the form of holes for holding the substrate device 101 with the additively manufactured object in the correct centered and rotated position in the support member. A slot 107 is present on the upper side of the base device 101 .

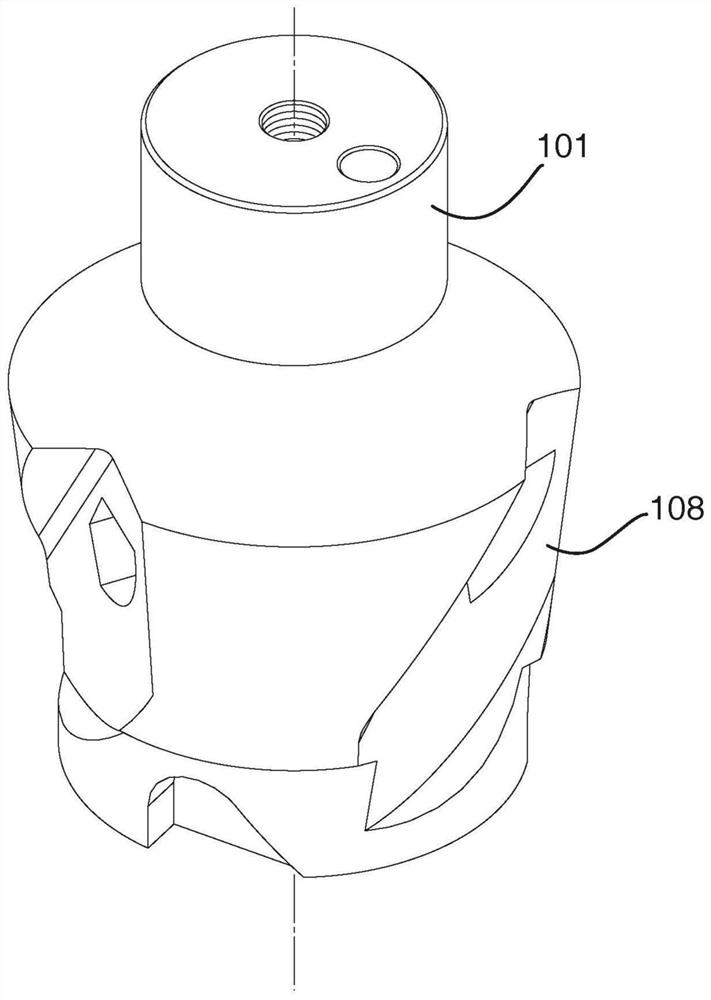

[0057] image 3 An embodiment of a substrate device 101 is shown with an additively manufactured object 108 built thereon, the additively manufactured object 108 being a milling tool body prior to post-processing machining.

[0058] Figure 4 A diagram of a substrate arrangement 101 is shown mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com