Electrophoresis display liquid, electrophoresis color display device and manufacturing method of device

An electrophoretic display and color display technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of long screen refresh time, poor color saturation, and poor display effect, so as to achieve better display effect and improve color quality. Saturation, the effect of reducing light penetration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

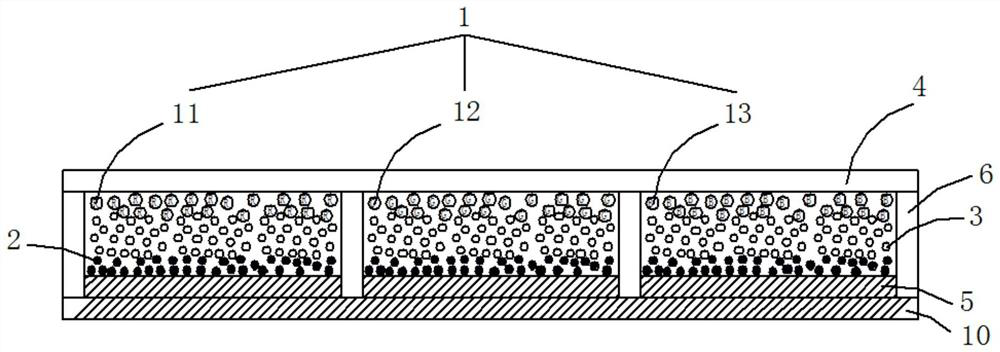

[0030] like figure 1 As shown, an electrophoretic display liquid provided by the present invention includes colored particles 1 and black particles 2 with opposite polarities, and neutral white particles 3 uniformly distributed in a solvent or a solvent mixture.

[0031] Wherein, the colored particles 1 are prepared by including but not limited to acetate, or organic resin, or siderite, or pigment dyed polymer. It should be noted that various pigments can be used for the colored particles 1 .

[0032] Wherein, the black particles 2 are made of manganese ferrite black spinel, or copper chromite black spinel, or carbon black, or zinc sulfide, or dyed black polymer materials. It should be noted that suitable materials for the black particles 2 include inorganic, organic or polymer particles.

[0033] Wherein, the white particles 3 are made of materials including but not limited to TiO2, or BaSO4, or ZnO, or Al2O3, or PbSO4. It should be noted that the neutral white particles 3...

Embodiment 2

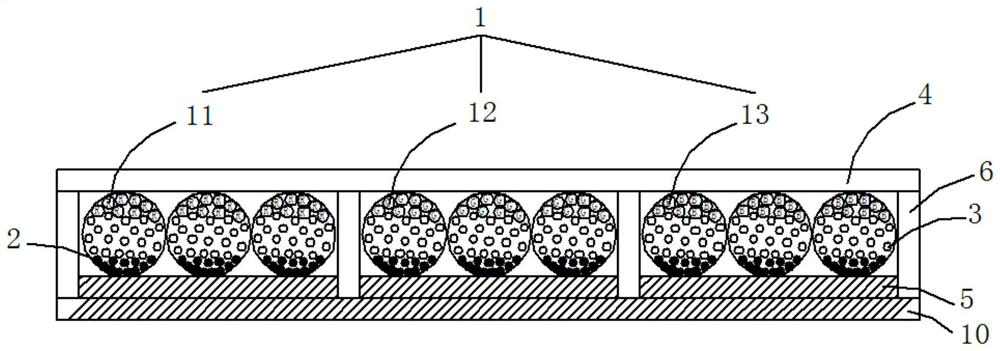

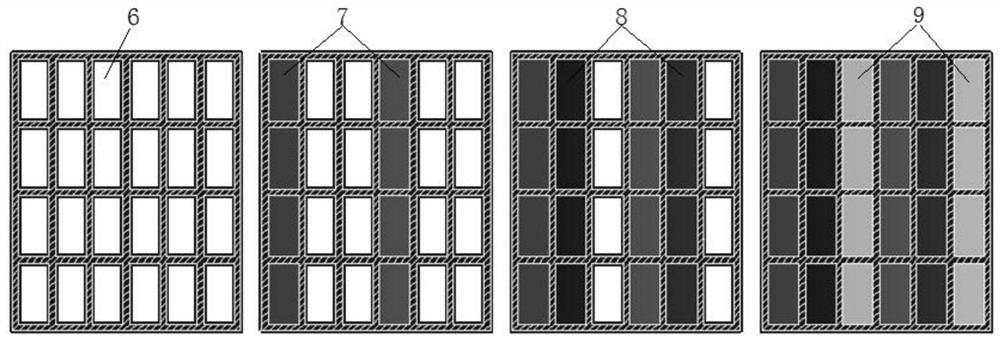

[0036] like figure 1 , figure 2 As shown, an electrophoretic color display device provided by the present invention also includes a plurality of arrays of microcup structures 6, and the electrophoretic liquid filled in the corresponding microcup structures 6 or the capsule suspension formed by the capsules filled with the electrophoretic liquid , the three microcup structures 6 form a pixel, and the three microcup structures 6 are respectively filled with corresponding electrophoretic fluid or capsule suspensions formed by capsules filled with electrophoretic fluid to form basic red display unit 7 and green display unit 9 and blue display unit 8. Specifically, the red display unit 7 includes charged red particles 11, charged black particles 2 and neutral white particles 3; the green display unit 9 includes charged green particles 12, charged black particles 2 and neutral white particles. The blue display unit 8 includes charged blue particles 13 , charged black particles 2 ...

Embodiment 3

[0039] like figure 1 , figure 2 and image 3 As shown, a method for manufacturing an electrophoretic color display device, comprising the following steps:

[0040] Coating a negative photoresist material on the common electrode layer 4 and fabricating a microcup structure 6 by mask photolithography or fabricating a microcup structure 6 on the pixel electrode layer 5;

[0041] Inject the electrophoretic liquid containing charged colored particles 1, charged black particles 2, and neutral white particles 3 or a capsule suspension formed by capsules filled with electrophoretic liquid into the microcup structure 6 of the corresponding color to form a red display Unit 7, green display unit 9 and blue display unit 8 form an RGB display unit;

[0042] The common electrode layer 4 and the pixel electrode layer 5 are pressed against each other and cured.

[0043] Specifically, the red display unit 7 includes charged red particles 11, charged black particles 2 and neutral white par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com