Automobile air inlet and outlet pipeline structure and coating process thereof

A technology of air inlet and outlet and pipeline, which is applied in the field of mechanical processing, and can solve problems such as temperature rise of air inlet and outlet, noise generation, and poor sound reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

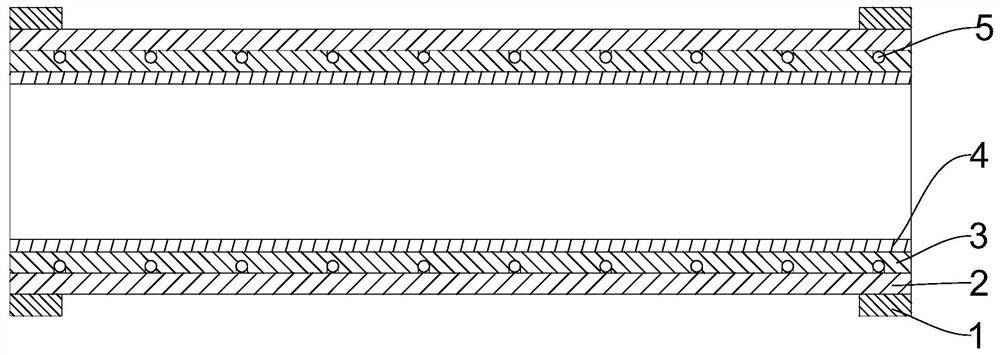

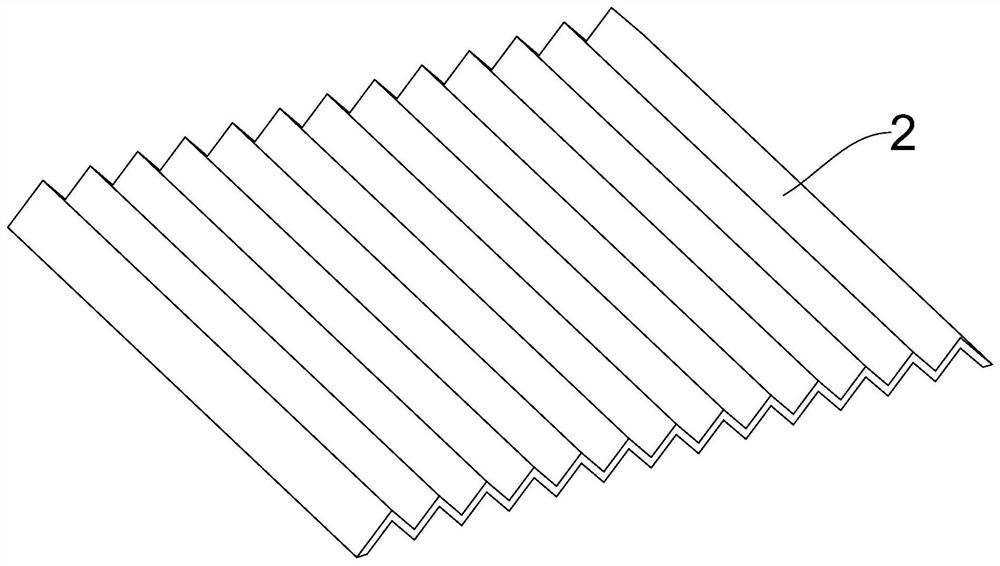

[0044] Please refer to figure 1 , figure 1Shown is a schematic structural diagram of the air inlet and outlet pipeline structure of an automobile in an embodiment of the present invention. This embodiment provides an air inlet and outlet pipeline structure for an automobile, including a pipe body 4 and a wrapping structure. The pipe body 4 is the channel of the air inlet and outlet pipes of the automobile, and the wrapping structure is mainly used for wrapping the air inlet pipe to achieve sound insulation effect. The wrapping structure includes a first wrapping layer 3 and a second wrapping layer 2, the first wrapping layer 3 is wrapped outside the pipe body 4, the second wrapping layer 2 is arranged close to the first wrapping layer 3, and the second wrapping layer The cladding layer 2 is clad on the first cladding layer 3 . The first cladding layer 3 can play the role of sound insulation and fire prevention, and the second cladding layer 2 can sandwich the first cladding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com