Cantilever type active and passive integrated orthogonal vibration isolation device with six degrees of freedom

A degree of freedom, active and passive technology, used in motor vehicles, transportation and packaging, non-rotational vibration suppression, etc., can solve the problems of difficult to achieve decoupling, large size, and heavy weight of voice coil motor actuators, and achieve improved directivity. Accuracy and stability, to achieve stiffness decoupling, to achieve the effect of double backup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

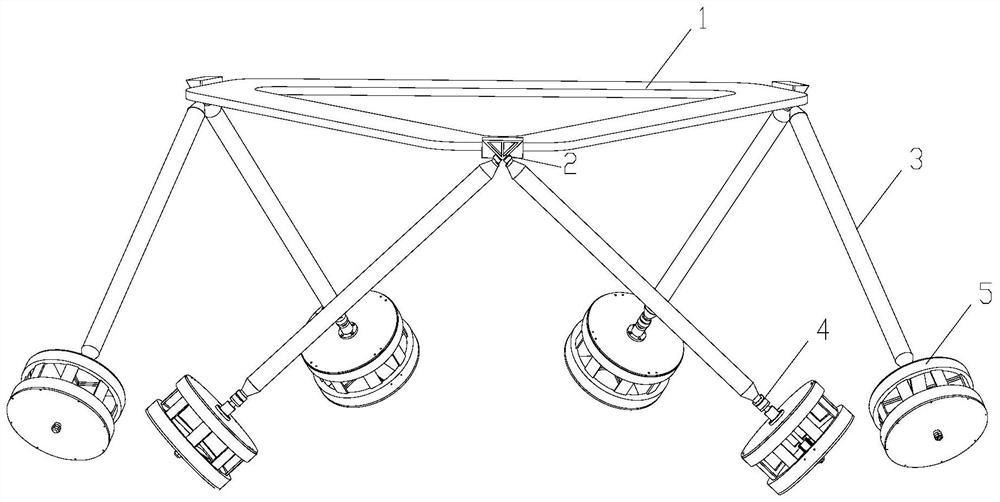

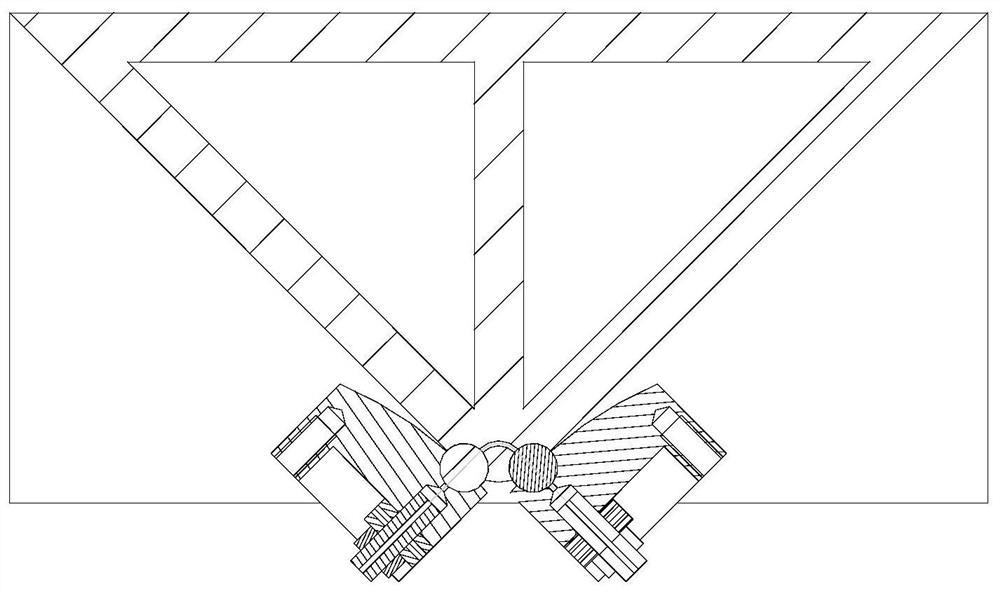

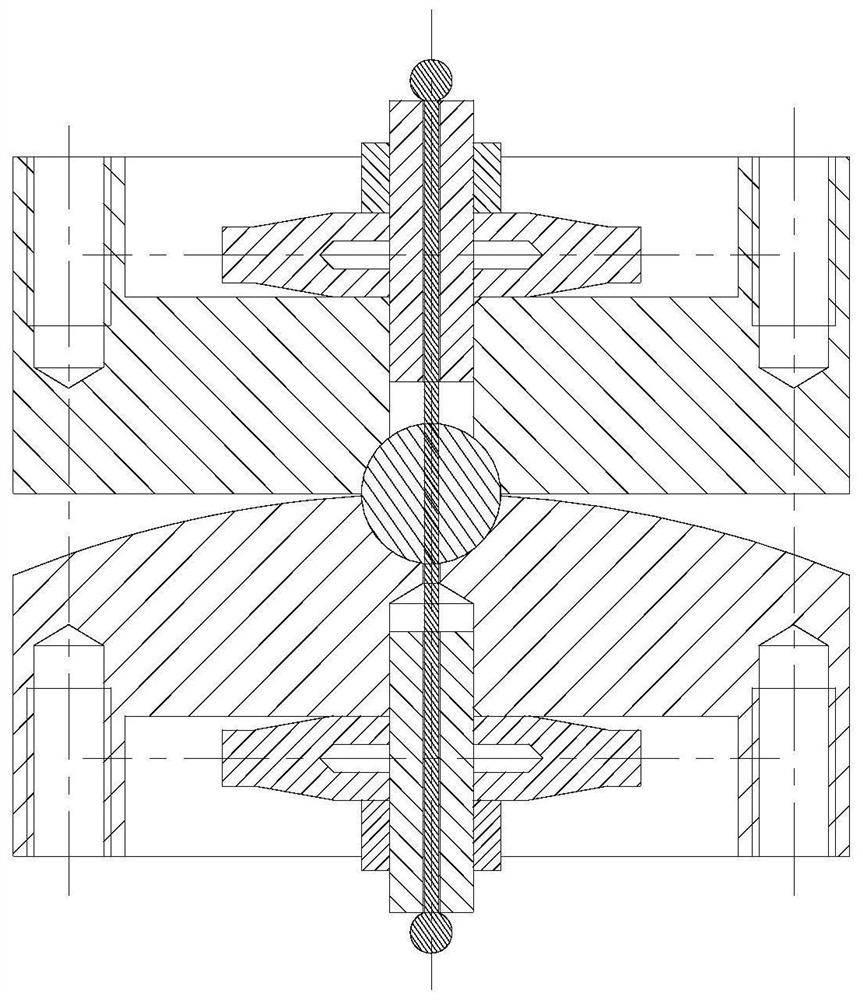

[0058] A cantilever beam type active and passive integrated orthogonal six-degree-of-freedom vibration isolation device of the present invention comprises: an upper platform (1), three three-joint quasi-zero rotational stiffness hinges (2), six carbon fiber rods (3), six two Joint quasi-zero rotational stiffness hinges (4), 6 active and passive integrated linear vibration isolation mechanisms (5); the upper platform (1) is connected to 6 carbon fiber rods ( 3) is connected at one end, and each three-joint quasi-zero-rotational stiffness hinge (2) is hinged with one end of two carbon fiber rods (3); the other end of each carbon fiber rod (3) is connected through two-joint quasi-zero-rotational stiffness hinge ( 4) Hinged with the active and passive linear vibration isolation mechanism (5), each active and passive linear vibration isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com