An inverted flat roof composite waterproof and thermal insulation structure and its construction method

A flat roof, inverted technology, applied in the direction of roof, roof covering, building roof, etc., can solve the problems of warping or separation at the edge, unstable connection at the edge, affecting the structural stability and thermal insulation effect, etc. It is not easy to achieve. The effect of separation, connection stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

[0040] The embodiment of the present application discloses an inverted flat roof composite waterproof and thermal insulation structure.

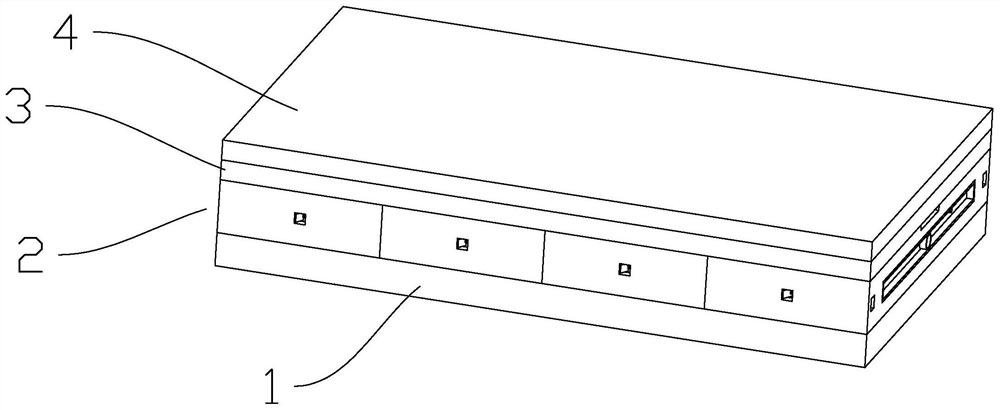

[0041] like figure 1 As shown, it includes a roof layer 1, an insulation layer 2, a waterproof layer 3 and a protective layer laid sequentially from bottom to top. Arranged in the length direction, one side of the insulation board 5 in the width direction is offset against the adjacent insulation board 5 .

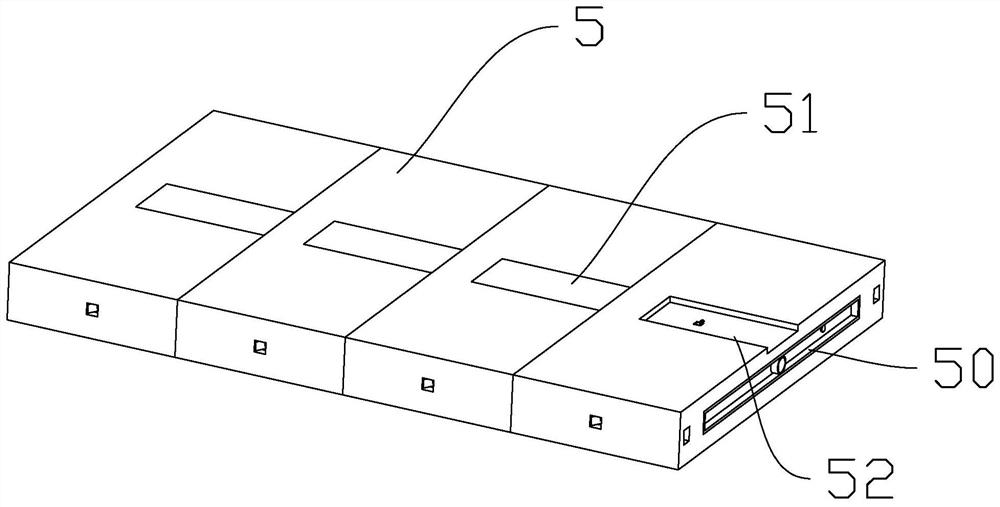

[0042] refer to figure 2 , image 3 One side in the width direction of the insulation board 5 is provided with an installation groove 50, and two horizontal plug-in boards are fixed on the other side in the width direction of the insulation board 5, and the plug-in boards are located at two edges of the insulation board 5 in the length direction. The plug board is arranged toward the side wall of the installation groove 50 of the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com