Electromagnetic induction annular heating laser cladding nozzle device and laser cladding device

A technology of heating laser and electromagnetic induction, which is applied in the direction of metal material coating process, coating, etc., can solve the problems of low cladding efficiency, and achieve the effect of solving low efficiency, improving efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is described in detail below, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

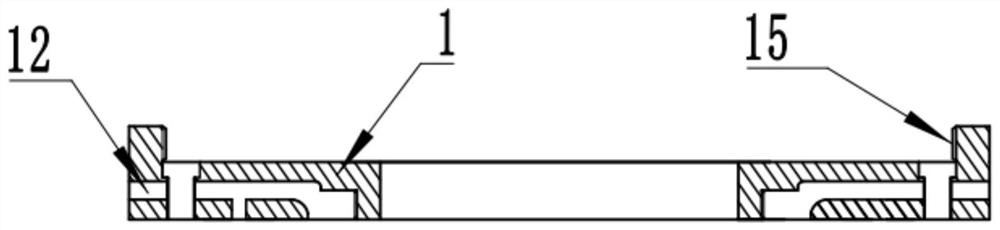

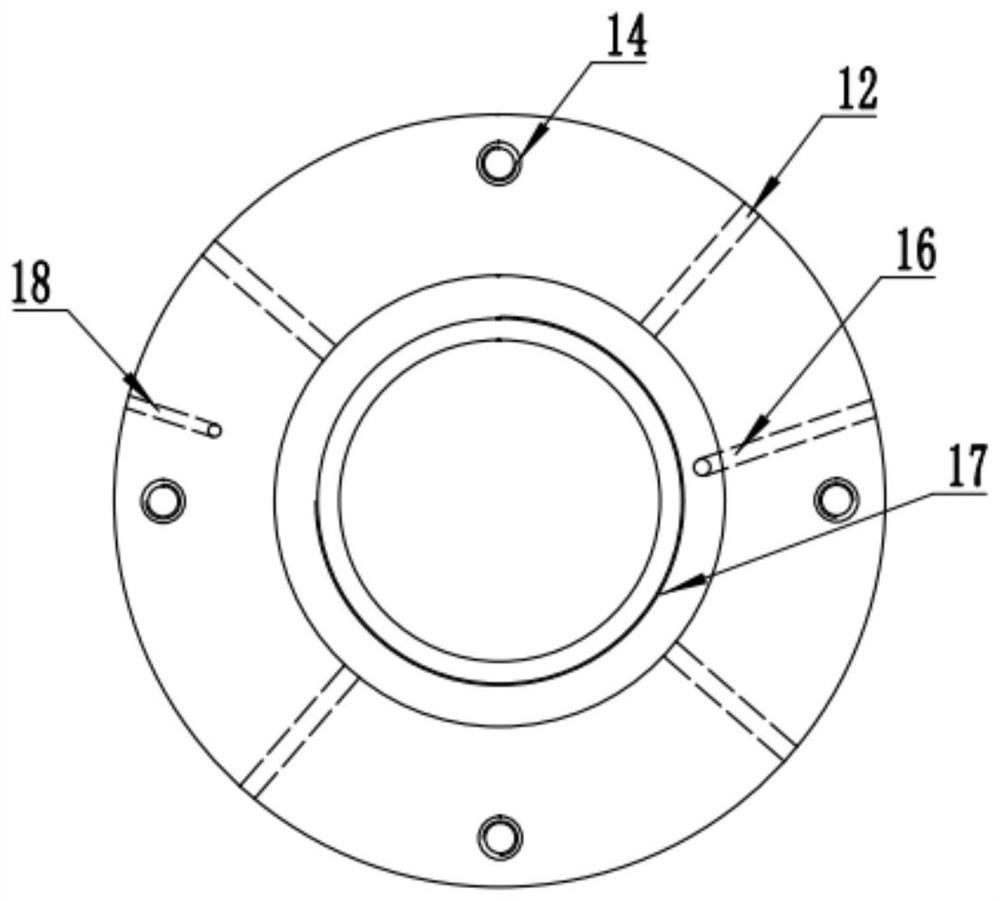

[0031] The invention is an electromagnetic induction annular heating laser cladding nozzle device, as attached figure 1 As shown, the nozzle device includes a connecting piece 1, an induction coil fixing piece 2, a ceramic inner ring 3, an induction heating coil 4, an induction heating power supply 5, a thermocouple 7, an induction heating power supply line 8, a thermocouple compensation wire 9, a thermoelectric Even power supply 10 and connecting bolt 11. The induction heating coil 4 is arranged in the induction coil fixing part 2, and is connected to the induction heating power supply 5 through an induction heating power line 8, and the ceramic inner ring 3 is arranged in the induction coil fixing part 2, And a powder flow channel 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com