Waterproof coating for Aga soil and preparation method of waterproof coating

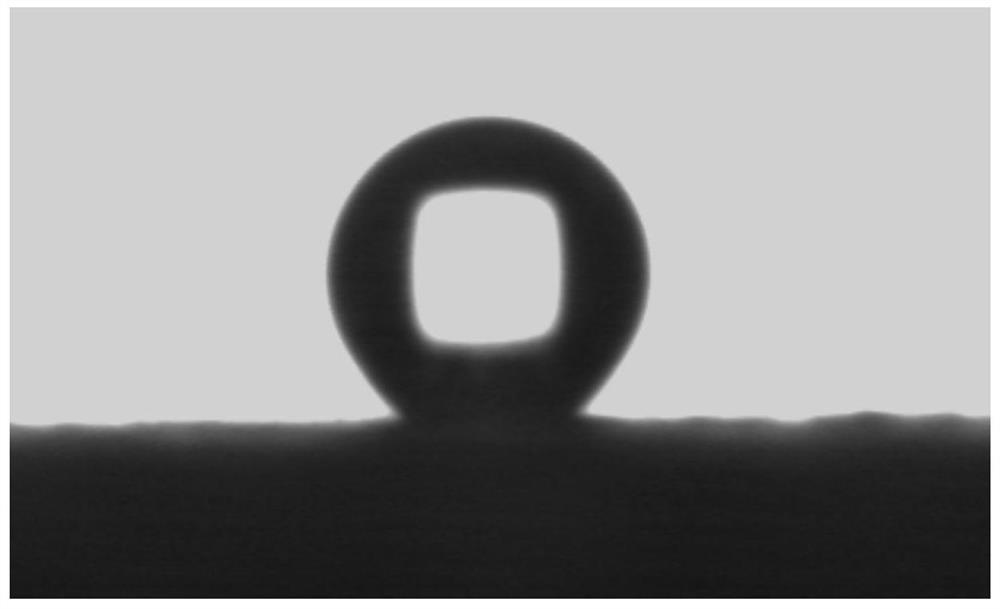

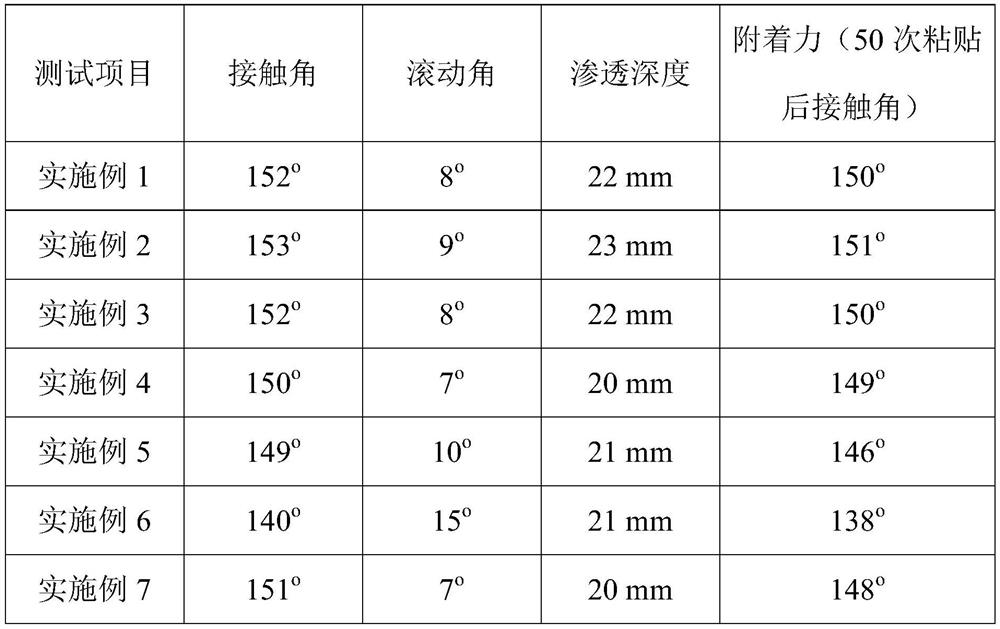

A technology of waterproof coating and Arga soil, applied in the direction of coating, etc., can solve the problems of limited waterproof effect and difficulty in forming a firm coating film, and achieve the effects of good adhesion, good long-term effect and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

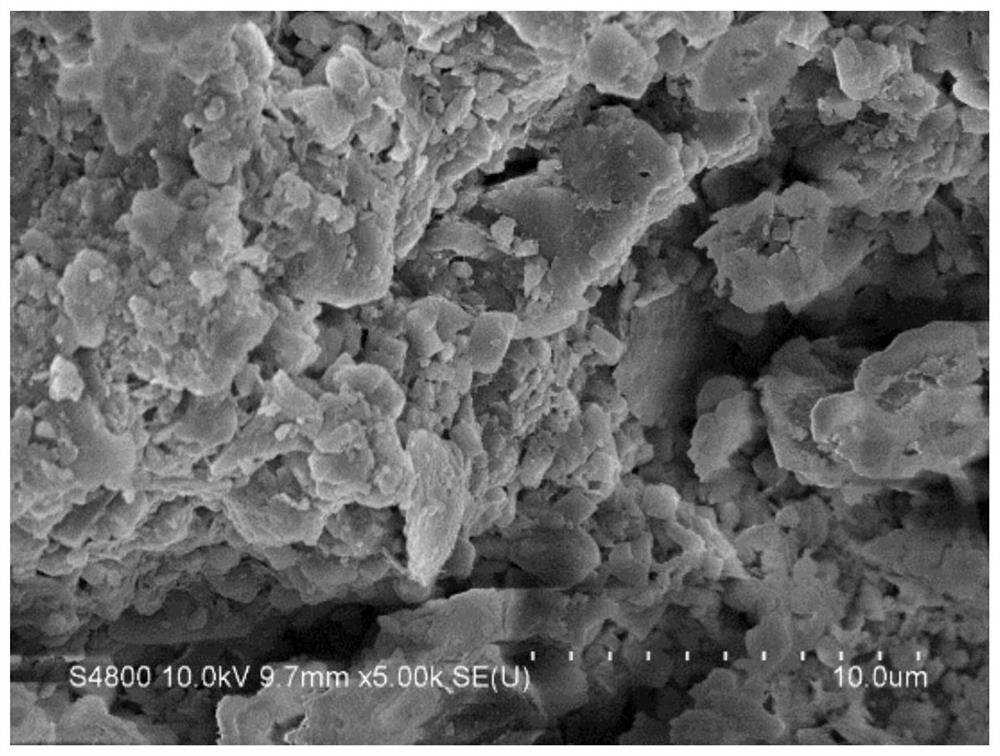

[0050] This preparation example provides a silane coupling agent modified nanoparticle I, which is prepared by the following preparation method:

[0051] (a) After uniformly mixing 200 mg of isopropanol and 20 mg of deionized water, add 20 mg of silane coupling agent KH570, and fully stir at 25°C for 2 hours to obtain a silane coupling agent dispersion;

[0052] (b) in the silane coupling agent dispersion that step (a) obtains, add the nanometer TiO of 200mg 2 , fully stirred at 25°C for 2h, filtered, and dried in an oven at 100°C for 6h to obtain silane coupling agent-modified nanoparticles I.

preparation example 2

[0054] This preparation example provides a silane coupling agent modified nanoparticle II, which is prepared by the following preparation method:

[0055] (a) After uniformly mixing 200 mg of isopropanol and 20 mg of deionized water, add 20 mg of silane coupling agent KH550, and fully stir at 25°C for 2 hours to obtain a silane coupling agent dispersion;

[0056] (b) in the silane coupling agent dispersion that step (a) obtains, add the nanometer TiO of 200mg 2 , fully stirred at 25° C. for 2 hours, filtered, and dried in an oven at 100° C. for 6 hours to obtain silane coupling agent-modified nanoparticles II.

preparation example 3

[0058] This preparation example provides a silane coupling agent modified nanoparticle III, which is prepared by the following preparation method:

[0059] (a) After uniformly mixing 200 mg of isopropanol and 20 mg of deionized water, add 20 mg of silane coupling agent KH560, and fully stir at 25°C for 2 hours to obtain a silane coupling agent dispersion;

[0060] (b) in the silane coupling agent dispersion that step (a) obtains, add the nanometer TiO of 200mg 2 , fully stirred at 25° C. for 2 hours, filtered, and dried in an oven at 100° C. for 6 hours to obtain silane coupling agent-modified nanoparticles III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com