A non-uniform superhydrophobic coating with enhanced droplet condensation effect and preparation method thereof

A super-hydrophobic coating and drop-like condensation technology, which is applied in coating, metal material coating process, liquid chemical plating, etc., can solve the problem of difficult processing, high cost of non-uniform wet surface preparation, and difficulty in large-scale Surface preparation and other issues, to achieve the effect of easy operation and realization, good condensation and desorption efficiency, good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

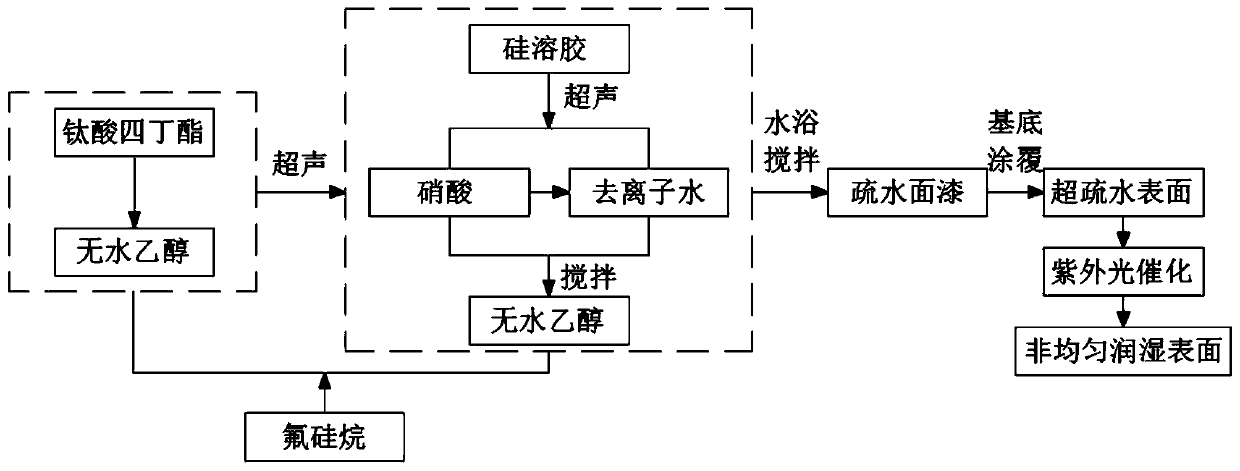

[0036] Such as Figure 1-5 As shown, a non-uniform superhydrophobic coating with enhanced droplet condensation effect, the surface of the superhydrophobic coating is made of TiO 2 and SiO 2 Nanoparticles are mixed and self-assembled, and have a nanoporous structure.

[0037] A kind of above-mentioned preparation method of the inhomogeneous superhydrophobic coating that has strengthened dropwise condensation effect, described preparation method comprises the steps:

[0038] (1) First, fill a beaker with 10mL of deionized water, add 1-2 drops of concentrated nitric acid with a concentration of 65wt.% to the beaker through a 2mL standard capacity dropper, and use pH test paper or a pH meter to measure and adjust the beaker. The pH value of the aqueous solution in the solution is 2.0, and the beaker is placed in an ultrasonic cleaner for ultrasonic dispersion, so that the nitric acid is uniformly dispersed and mixed in deionized water;

[0039] (2) Add 0.5 g of silica sol dropw...

Embodiment 2

[0051] A non-uniform superhydrophobic coating with enhanced droplet condensation effect, the surface of the superhydrophobic coating is made of TiO 2 and SiO 2 Nanoparticles are mixed and self-assembled, and have a nanoporous structure.

[0052] A kind of above-mentioned preparation method of the inhomogeneous superhydrophobic coating that has strengthened dropwise condensation effect, described preparation method comprises the steps:

[0053] (1) First, fill a beaker with 10mL of deionized water, add 1-2 drops of concentrated nitric acid with a concentration of 68wt.% to the beaker through a 2mL standard capacity dropper, and use pH test paper or a pH meter to measure and adjust the beaker. The pH value of the aqueous solution in the solution is 2.5, and the beaker is placed in an ultrasonic cleaner for ultrasonic dispersion, so that the nitric acid is uniformly dispersed and mixed in deionized water;

[0054] (2) Add 1.0 g of silica sol dropwise into the beaker of step (1)...

Embodiment 3

[0065] A non-uniform superhydrophobic coating with enhanced droplet condensation effect, the surface of the superhydrophobic coating is made of TiO 2 and SiO 2 Nanoparticles are mixed and self-assembled and stacked, and have a nanoporous structure. The preparation method of the non-uniform superhydrophobic coating includes the following steps:

[0066] (1) First, fill a beaker with 10mL of deionized water, add 1-2 drops of concentrated nitric acid with a concentration of 65wt.% to the beaker through a 2mL standard capacity dropper, and use pH test paper or a pH meter to measure and adjust the beaker. The pH value of the aqueous solution in the solution is 4.0, and the beaker is placed in an ultrasonic cleaner for ultrasonic dispersion, so that the nitric acid is uniformly dispersed and mixed in deionized water;

[0067] (2) Add 1.5 g of silica sol dropwise to the beaker of step (1) using a dropper, and continue ultrasonic dispersion for 10 min;

[0068] (3) Measure 70 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com