Energy-saving and environment-friendly chemical water pollution treatment equipment

A technology of energy saving, environmental protection and treatment equipment, applied in the field of water pollution treatment, can solve the problems of reducing the diameter of the concave pipe, affecting the flow speed of sewage and the discharge volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

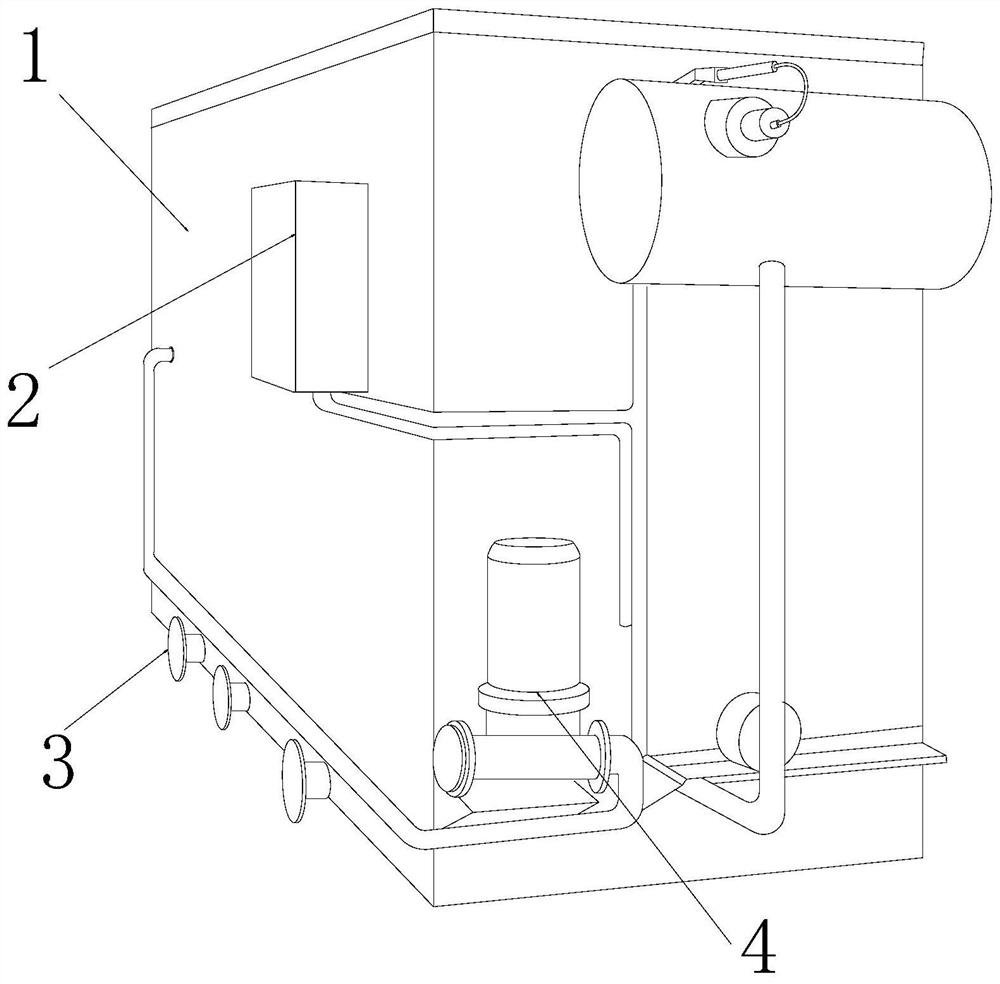

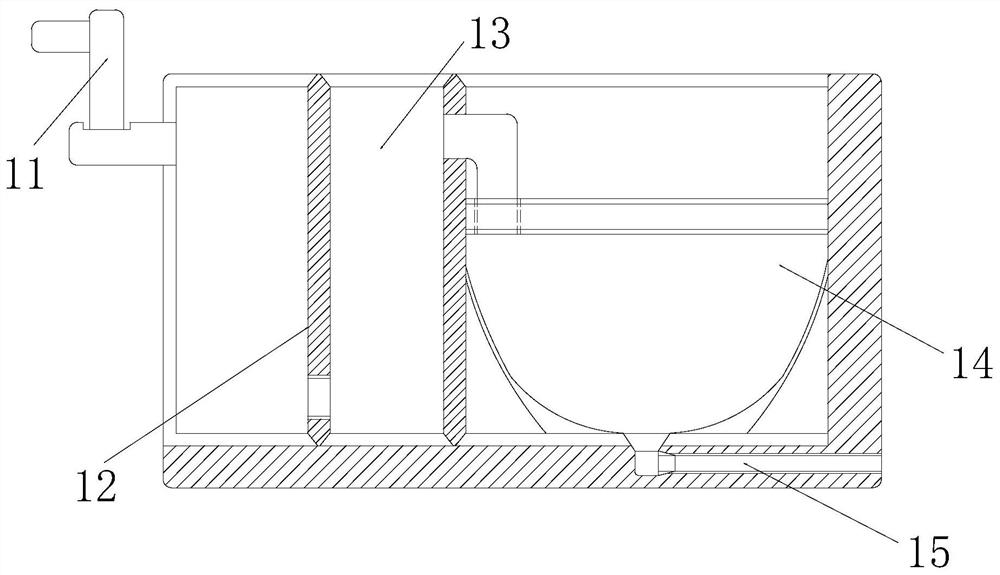

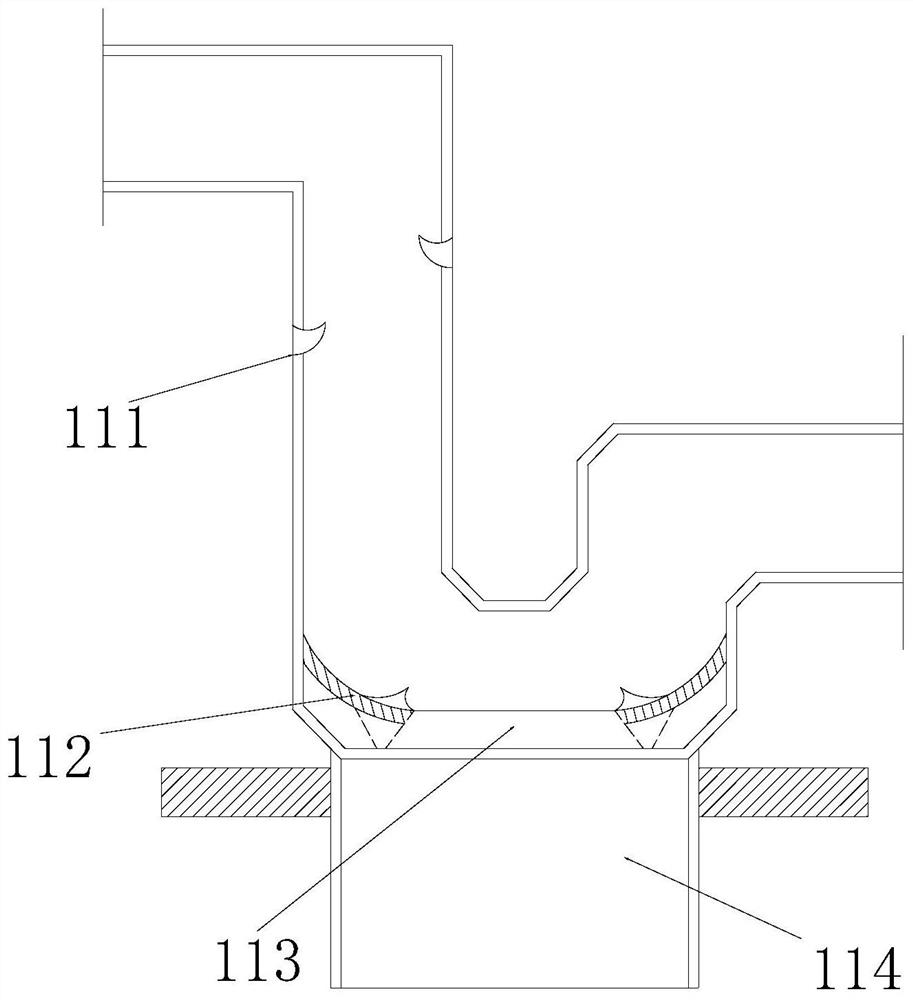

[0026] as attached figure 1 To attach Figure 5 Shown:

[0027] The present invention provides an energy-saving and environment-friendly chemical water pollution treatment equipment, the structure of which includes a treatment bin 1, a control box 2, a water outlet 3, and a motor 4, the control box 2 is fixedly installed on the left end surface of the outer side of the treatment bin 1, and the The control box 2 is located directly above the water outlet 3, the water outlet 3 is embedded and installed on the outer lower end surface of the processing chamber 1, the motor 4 is located under the right side of the control box 2, and the processing chamber 1 includes a sedimentation mechanism 11 , partition 12, oxidation chamber 13, sedimentation tank 14, sewage outlet 15, the sedimentation mechanism 11 is inlaid on the upper left side of the partition 12, and the outer end surface of the partition 12 is inlaid and mounted on the inner side of the processing chamber 1 On the end f...

Embodiment 2

[0033] as attached Figure 6 To attach Figure 8 As shown: the discharge mechanism 114 includes a movable plate 141, a closing mechanism 142, a slide rail 143, and a rotating shaft 144. The movable plate 141 is symmetrically installed on the inner upper end surface of the discharge mechanism 114, and the closing mechanism 142 is mounted on the On the left and right sides of the upper end of the movable plate 141, the slide rail 143 is inlaid on the inner end surface installed on the discharge mechanism 114, and the rotating shaft 144 is movably engaged and installed on the outer surface of the upper end of the slide rail 143, and the groove of the slide rail 143 The rail adopts a ladder-type symmetrical groove, which can effectively avoid the phenomenon of detachment during the sliding process while ensuring sliding.

[0034]Wherein, the closing mechanism 142 includes an inlaid magnetic groove 421, a ball 422, a closing plate 423, an inlaid shaft 424, and an elastic rope 425....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com