Air drying line upper and bottom layer flow guide mechanism for processing cured food

A technology for food processing and diversion mechanism, which is used in dryers, non-progressive dryers, and drying solid materials without heating. Diversion discharge, oil solidification and accumulation are difficult to clean, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

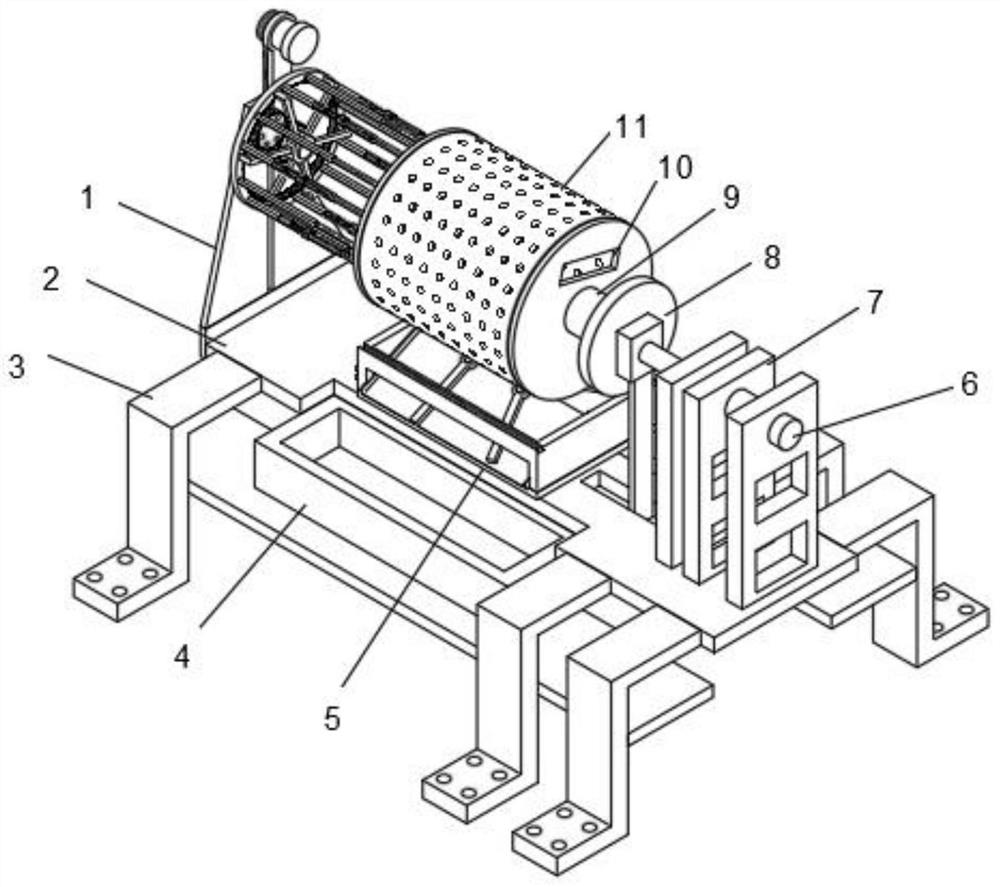

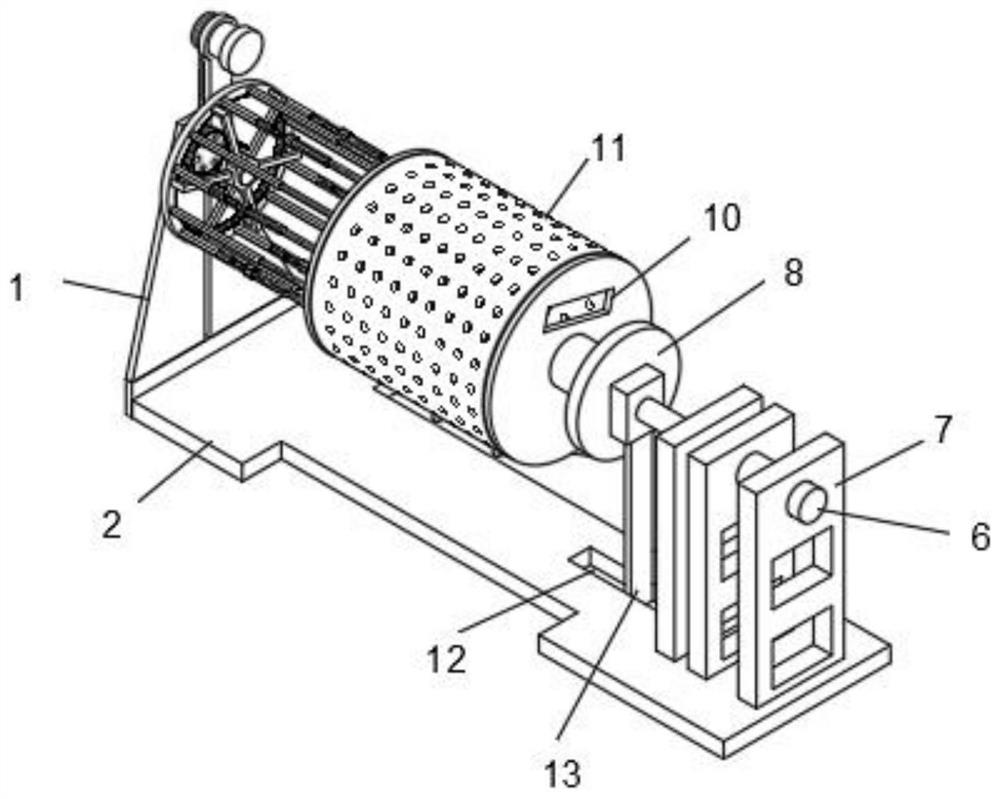

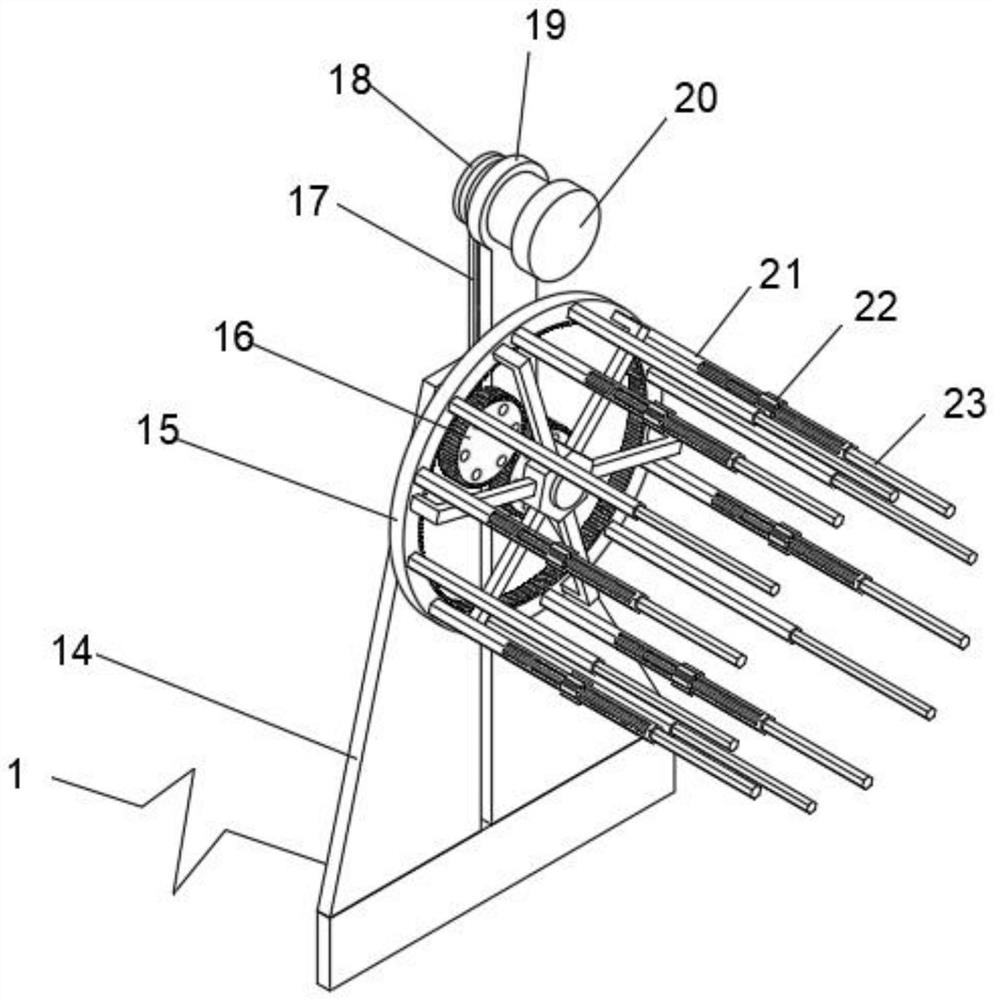

[0040] Such as Figure 1-2 , a bottom diversion mechanism on an air drying line for wax food processing, comprising a rotation control device 1, a support frame 2, a support leg 3, a collection frame 4, a diversion device 5, a rotating connection clamp shaft 9, a pick-and-place opening 10 and Rotate the air-drying cylinder 11, the support legs 3 are symmetrically and fixedly connected to both sides of the support frame 2, the rotation control device 1 is fixedly connected to the upper part of one end of the support frame 2, and the rotating air-drying cylinder 11 is fixedly connected to the rotation control device 1 The front end of the front end, the access opening 10 is opened at one end of the rotating air-drying cylinder 11, the flow guide device 5 is fixedly installed in the middle of the upper end of the support frame 2, and the flow guide device 5 is located directly below the rotating air-drying cylinder 11 , the collection frame 4 is distributed on both sides of the s...

Embodiment 2

[0042] Such as Figure 1-2 , as a further optimization scheme of the above-mentioned embodiment: a bottom flow guide mechanism on an air drying line for wax food processing, including a rotation control device 1, a support frame 2, a support leg 3, a collection frame 4, a flow guide device 5, a rotation connection Clamping shaft 9, pick-and-place port 10 and rotating air-drying cylinder 11, described support legs 3 are symmetrically fixedly connected on both sides of support frame 2, and described rotation control device 1 is fixedly connected on one end upper part of support frame 2, and described rotating air-dried The barrel 11 is fixedly connected to the front end of the rotation control device 1, the pick-and-place opening 10 is opened at one end of the rotating air-drying barrel 11, the flow guiding device 5 is fixedly installed in the upper middle part of the support frame 2, and the flow guiding device 5 is located directly below the rotating air-drying cylinder 11, th...

Embodiment 3

[0044] Such as Figure 1-2 , as a further optimization scheme of the above-mentioned embodiment: a bottom flow guide mechanism on an air drying line for wax food processing, including a rotation control device 1, a support frame 2, a support leg 3, a collection frame 4, a flow guide device 5, a rotation connection Clamping shaft 9, pick-and-place port 10 and rotating air-drying cylinder 11, described support legs 3 are symmetrically fixedly connected on both sides of support frame 2, and described rotation control device 1 is fixedly connected on one end upper part of support frame 2, and described rotating air-dried The barrel 11 is fixedly connected to the front end of the rotation control device 1, the pick-and-place opening 10 is opened at one end of the rotating air-drying barrel 11, the flow guiding device 5 is fixedly installed in the upper middle part of the support frame 2, and the flow guiding device 5 is located directly below the rotating air-drying cylinder 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com