Protective device installed on rear portion of vehicle

A protection device, a technology for the rear of a vehicle, applied to vehicle components, vehicle safety arrangements, bumpers, etc., can solve the problems of high mortality rate and low mortality rate, achieve low cost, reduce vehicle damage, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

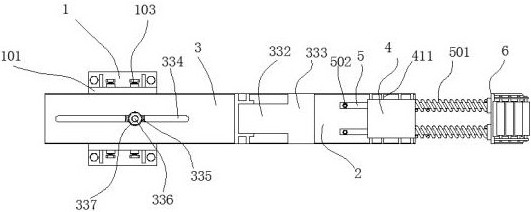

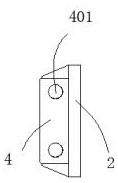

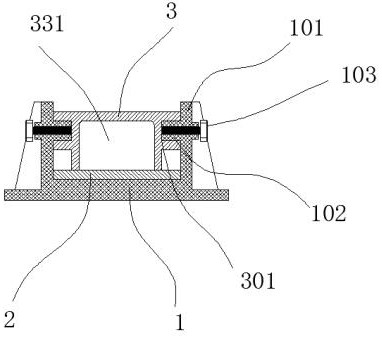

[0033] A protection device installed at the rear of a vehicle, including connectors 1 installed on both sides of the vehicle girder, the connector 1 is made of Q235 ordinary carbon structural steel with a wall thickness of 6mm~12mm; the connection between the connector 1 and the vehicle girder is made of Bolting or welding is fixed; and the steel plate 2 assembled in the connecting piece 1, the surface of the connecting piece 1 is casted with two upper and lower clamping plates 101, the two clamping plates 101 Sliders 102 are arranged on the opposite surfaces, and screw holes passing through the sliders 102 are arranged on the outside of the clamping plate 101, and screws 103 are assembled in the screw holes; the surface of the steel plate 2 is welded There is a shell plate 3, the upper and lower ends of the shell plate 3 are casted to form a chute 301, the slider 102 fits the chute 301, the screw 103 is screwed in and resists the chute 301, at this time the The shell plate 3 ...

Embodiment 2

[0035]A cavity 331 is formed between the shell plate 3 and the steel plate 2, and a rubber insert strip 332 is inserted into the cavity 331, and the right end of the insert strip 332 is injection-molded to form a terminal 333, so that There is a space between the end 333 and the steel pipe 5, and before the spring 501 is compressed to the limit, the steel pipe 5 contacts the end 333; a bar-shaped groove 334 is arranged transversely on the surface of the shell plate 3, A baffle plate 335 is arranged in the cavity 331, and a bolt 336 is screwed into the upper end of the baffle plate 335, and a nut 337 is fitted after the upper end of the bolt 336 passes through the strip groove 334, and the nut 337 After tightening, the baffle plate 335 is fixed; the effect of the above structure is that when the force of the collision is too large, the spring will be compressed rapidly. Damage to the spring. For this reason, we designed the above-mentioned structure. In the above-mentioned str...

Embodiment 3

[0037] An inner hole 338 is arranged in the end head 333, and an inner ring piece 339 is formed by injection molding inside the inner hole 338. The inner hole 338 passes through the end head 333 to the right, and the diameter of the inner hole 338 greater than the outer diameter of the steel pipe 5, the inner diameter of the inner ring piece 339 is smaller than the outer diameter of the steel pipe 5; the inner hole 338 can enter the steel pipe, and the steel pipe squeezes the inner ring piece 339 one by one after insertion to achieve the effect of deceleration If the above-mentioned structure is not set, then the nozzle of the steel pipe 5 has a shear force, which may cause the steel pipe 5 to be inserted into the end, and cause the connection between the steel pipe 5 and the end. bomb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com