A multi-degree-of-freedom tie rod attitude adjustment and positioning method

A positioning method and a technology of degrees of freedom, applied in the measurement of positioning in boring machines/drilling machines, drilling/drilling equipment, metal processing equipment, etc., can solve problems such as low operating efficiency and poor drilling accuracy, and avoid drilling Deviation, improve the efficiency of assembly and adjustment, and reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

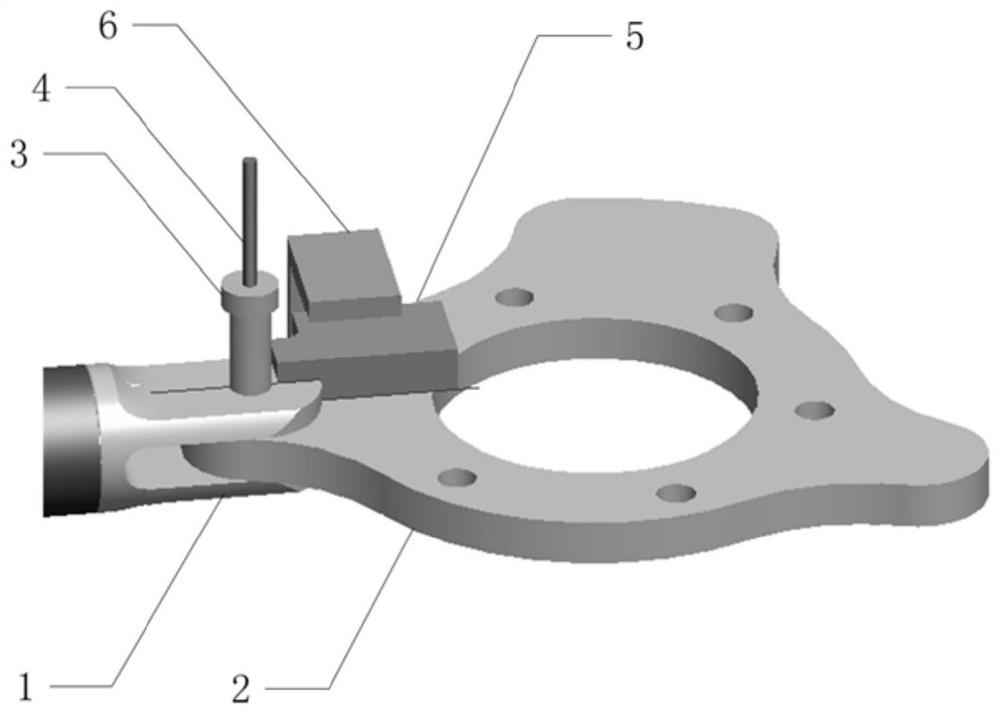

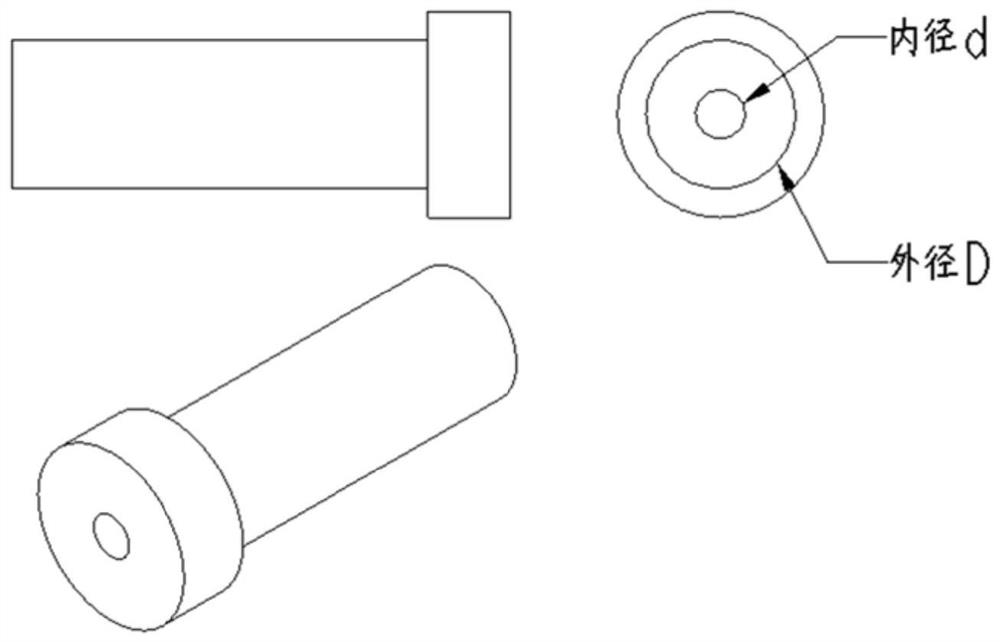

[0032] A multi-degree-of-freedom tie rod attitude measurement and positioning method, which can realize the precise installation of the tie rod joint and the adapter flange, and ensure the dimensional accuracy and shape tolerance of the matching center hole, such as Figure 4 As shown, by establishing the installation datum plane of the satellite storage tank, the transfer flange and the tie rod joint are aligned. Cooperate with the sleeve and the drill bit to continue screwing the center hole to drill and ream the hole. Finally, ream and ream the removed tie rod joint and transfer flange. After the center hole is drilled, complete the transfer flange and tie rod joint positioning. Measure and adjust.

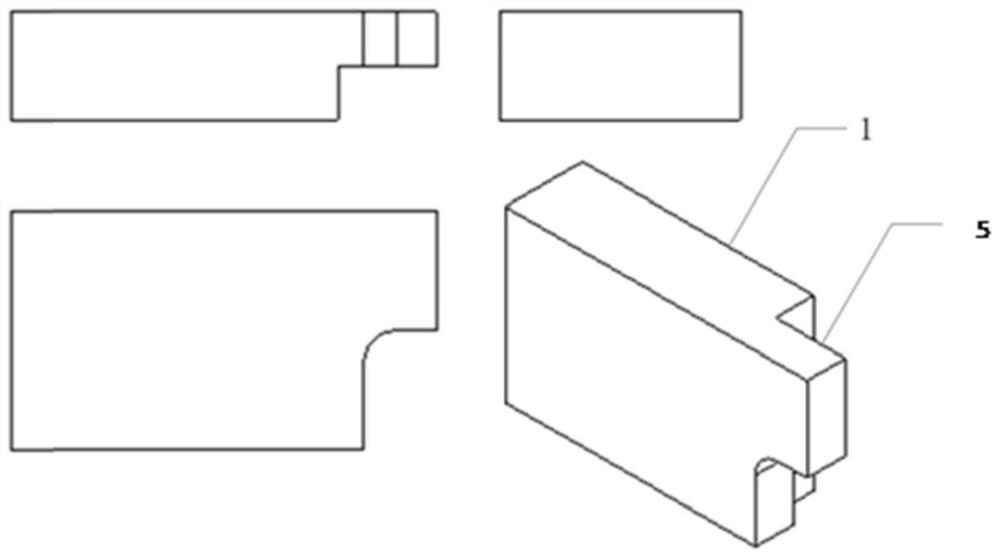

[0033] like figure 1 , figure 2 , Figure 5 As shown, the positioning device includes: 1 is the tie rod joint, 2 is the adapter flange, 3 is the drill sleeve, 4 is the drill bit, 5 is the positioning device, and 6 is the fixed cardan; during the matching process, each tie r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com