Device and method for removing carbon dioxide in urea and polyol reaction tail gas

A carbon dioxide and polyol technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of removal, lower liquid ammonia yield, consumption of ammonia gas, etc. Good effect, complete removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

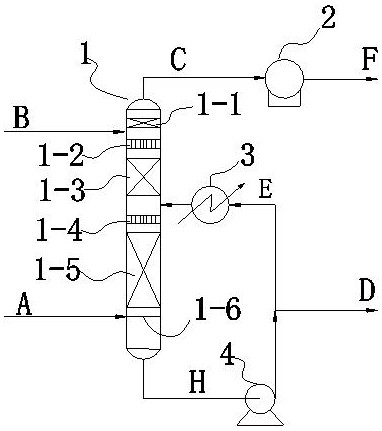

[0044] figure 1 A one-stage circulating caustic scrubbing carbon removal device is shown.

[0045] The one-stage circulating alkali washing carbon removal device includes an alkali washing tower 1 , a vacuum pump 2 , an alkali washing circulating liquid cooler 3 , and an alkali washing liquid circulating pump 4 .

[0046] One-stage circulating alkali cleaning carbon removal device The inside of the alkali washing tower 2 is provided with a demister 1-1, a fresh lye liquid distributor 1-2, a fresh lye alkali washing packing 1-3, and an alkali washing Circulating liquid distributor 1-4, alkali washing circulating liquid alkali washing packing 1-5, gas distributor 1-6.

[0047] The upper part of the alkali washing tower kettle of the one-stage circulating alkali cleaning decarbonization device is adjacent to the alkali washing circulating fluid and the lower part of the alkali washing packing is provided with an inlet for the reaction tail gas A of urea and polyol connected to t...

Embodiment 2

[0051] The pressure of the alkali washing tower 1 is controlled at -30kPaG, B is an aqueous solution of sodium hydroxide with a concentration of 15wt%, C is the tail gas produced by the reaction of urea and 1,2-propylene glycol, the temperature of the alkali washing tower is controlled at 40°C, and the liquid H in the bottom of the tower is The concentration of sodium hydroxide is controlled at 1wt%, and all the other processes are as described in Example 1. Analyze the composition of the gas C at the top of the alkali washing tower 1, which does not contain carbon dioxide.

Embodiment 3

[0053] The pressure of the alkali washing tower 1 is controlled at -70kPaG, B is an aqueous solution of sodium hydroxide with a concentration of 30wt%, C is the tail gas produced by the reaction of urea and glycerin, the temperature of the alkali washing tower is controlled at 10°C, and the sodium hydroxide in the tower still liquid H Concentration is controlled at 2wt%, and all the other processes are as described in Example 1. Analyze the composition of the gas C at the top of the alkali washing tower 1, which does not contain carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com