Wheel edge circular ring type service parking brake

A technology of parking brake and service brake, which is applied in the direction of brake type, axial brake, brake actuator, etc., and can solve the problem that the drum brake is not as good as the disc brake, the control lever occupies a large space, and the ability to stand on a slope Weakness and other problems, to achieve the effect of improving service braking performance, saving layout space, and reliable parking brake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, further describe the present invention.

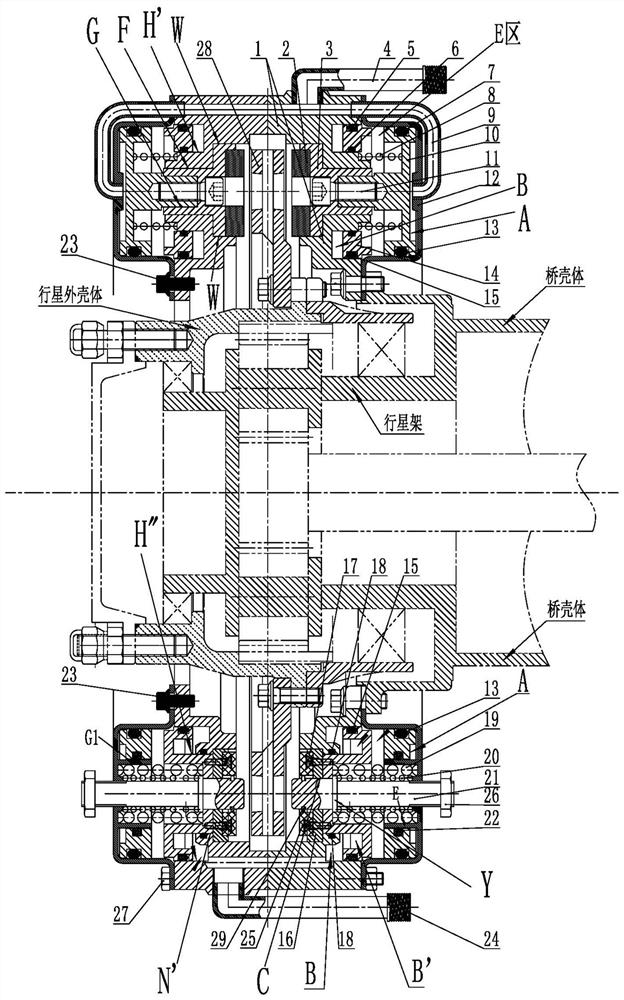

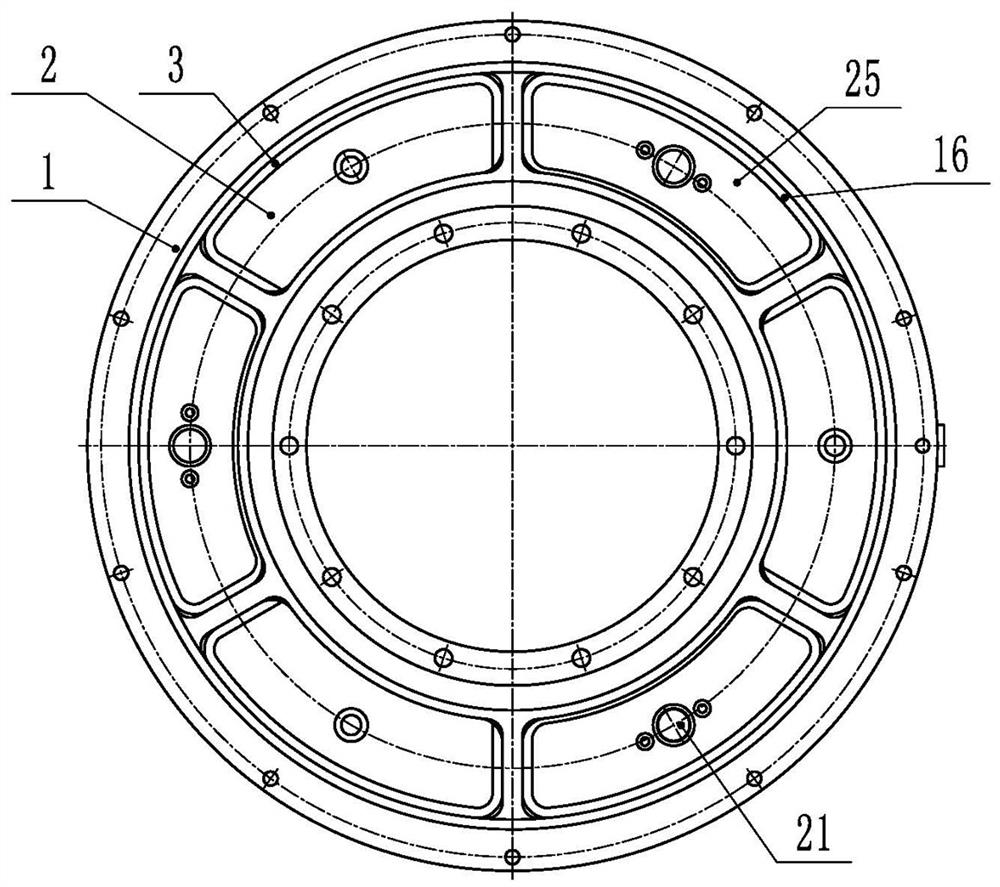

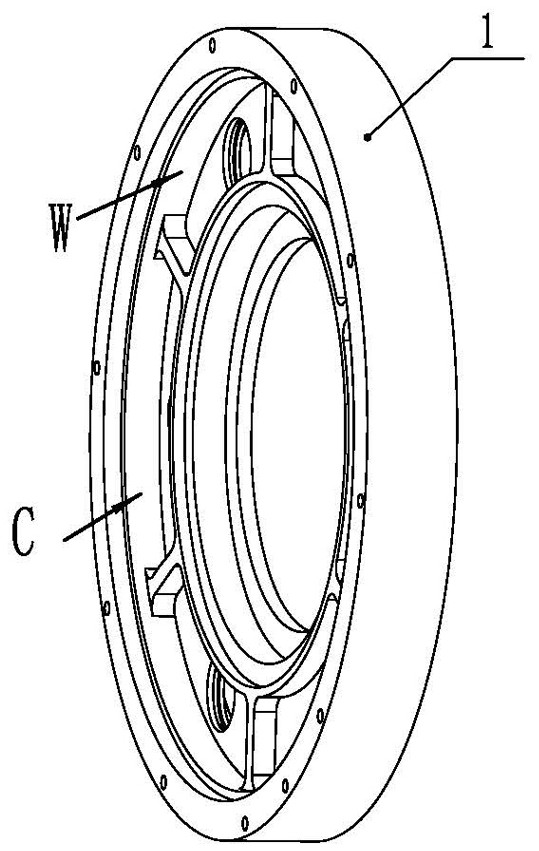

[0025] Such as figure 1 As shown in the present invention, the wheel rim ring type service parking brake, the left brake unit and the right brake unit which are symmetrically arranged on the left and right sides and have the same function and structure, respectively have driving brake units in the left brake unit and the right brake unit. Two systems of brake and parking brake, including housing 1, brake pad 2, service brake base plate 3, service brake main air pipe 4, first outer ring air seal 5, first small air seal ring 6, second Second outer ring air seal 7, service brake return spring 8, service brake bronchus 9, service brake air chamber disc 10, countersunk screw 11, ring cover 12, second inner ring air seal 13, parking brake air Disk 14, first inner ring air seal 15, parking brake bottom plate 16, screw 17, small parking air seal 18, parking brake return spring 19, taper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com