Tram Passive Hydraulic Braking System

A technology for hydraulic braking and trams, which is applied in the direction of brakes, braking transmission devices, vehicle components, etc., and can solve the problems of various braking modes, large braking force, and small installation space that cannot meet the braking force requirements of trams , to achieve the effect of reliable parking brake, easy maintenance, and avoiding frequent start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

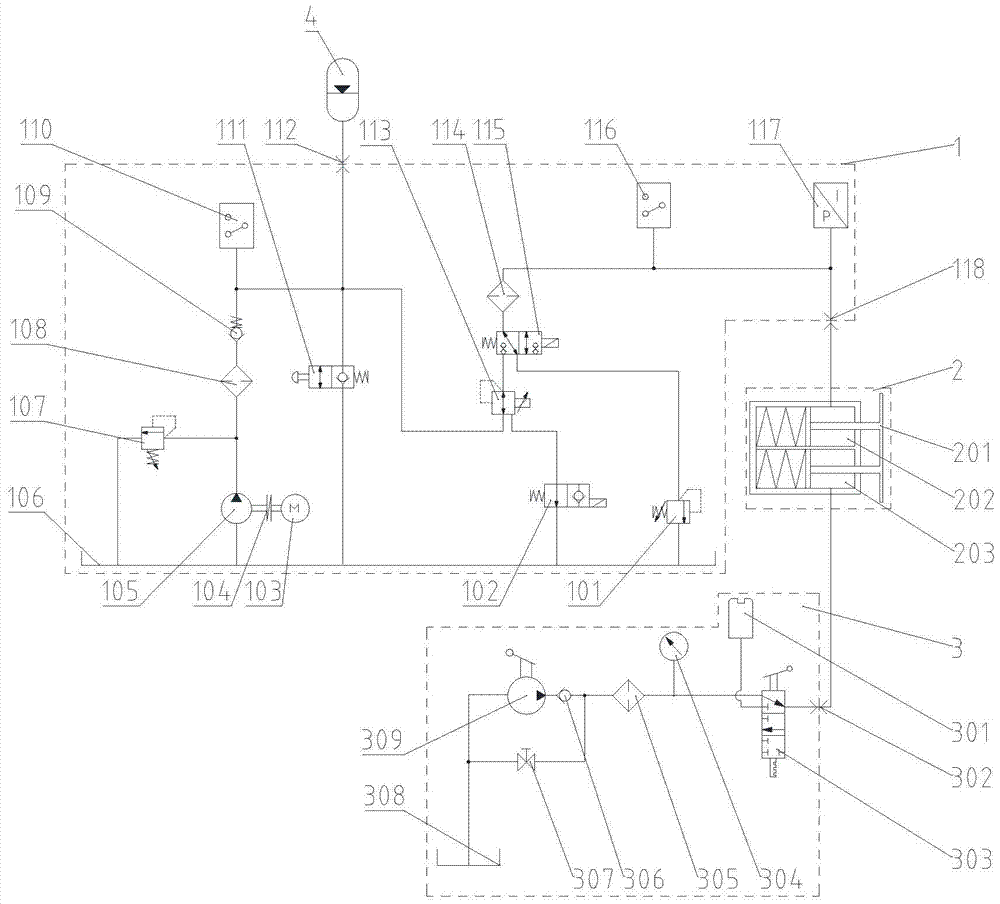

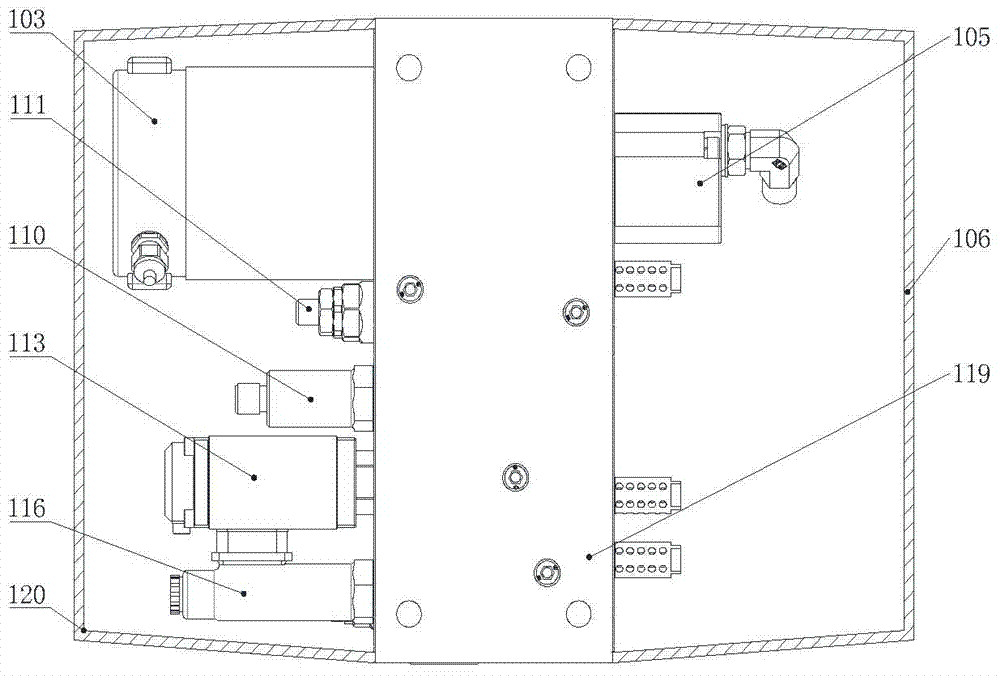

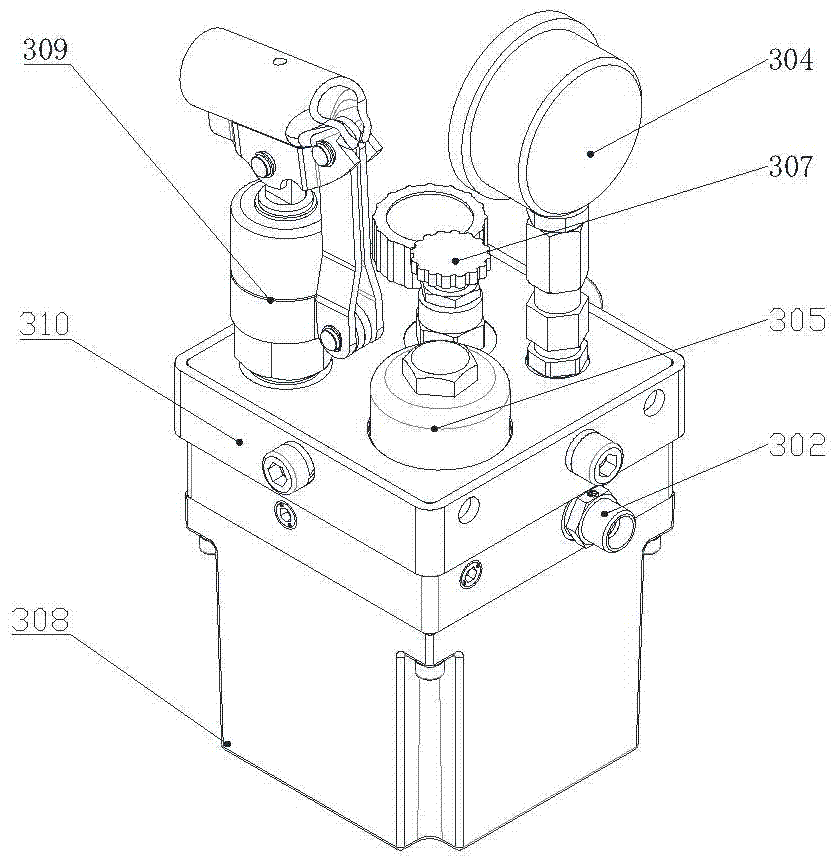

[0016] The tram passive hydraulic braking system includes an automatic braking hydraulic unit 1, an accumulator 4 and a control system. The automatic braking hydraulic unit 1 includes a hydraulic pump 105, a first oil tank 106, a motor 103, a coupling 104, an overflow The flow valve 107, the first one-way valve 109, the manual release valve 111 and the first filter 108; the hydraulic pump 105 is connected with the motor 103 through the shaft coupling 104, and the outlet of the hydraulic pump 105 has two paths, one of which passes through the overflow valve 107 Connect back to the first oil tank 106, and connect to the first one-way valve 109 through the first filter 108; the overflow valve 107 is used to limit the maximum pressure of the system and play a protective role. The accumulator 4 is installed on the automatic brake hydraulic unit 1 through the accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com