Antibacterial mildew-proof high-temperature vulcanized silicone rubber and preparation method thereof

A high-temperature vulcanization, antibacterial and anti-mildew technology, applied in the field of rubber material manufacturing, can solve the problems of short anti-bacterial duration, narrow application area, insufficient mechanical and physical properties of anti-bacterial and anti-mildew room temperature silicone rubber, etc., to achieve long-lasting sterilization effect and high usability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

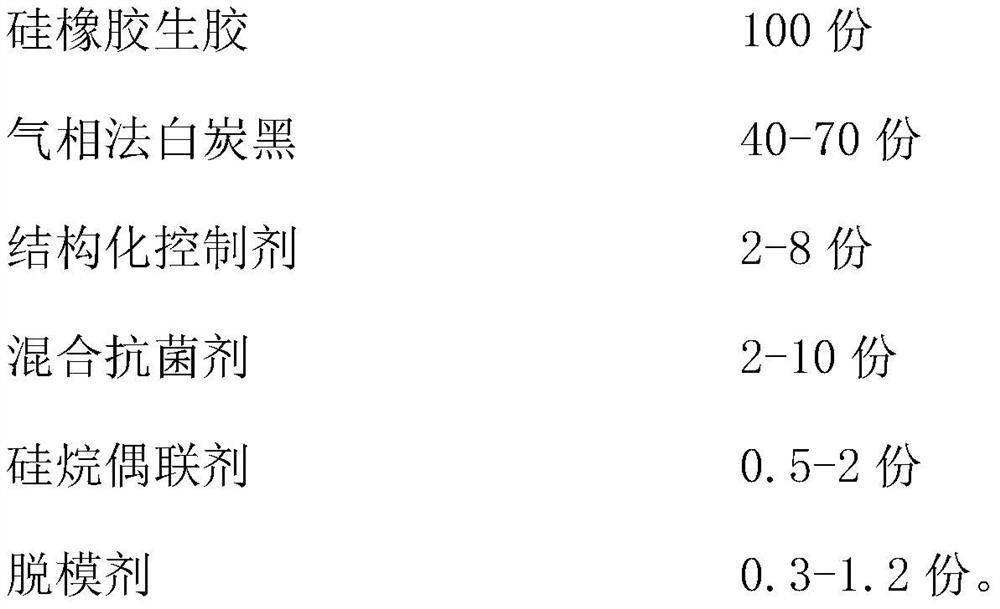

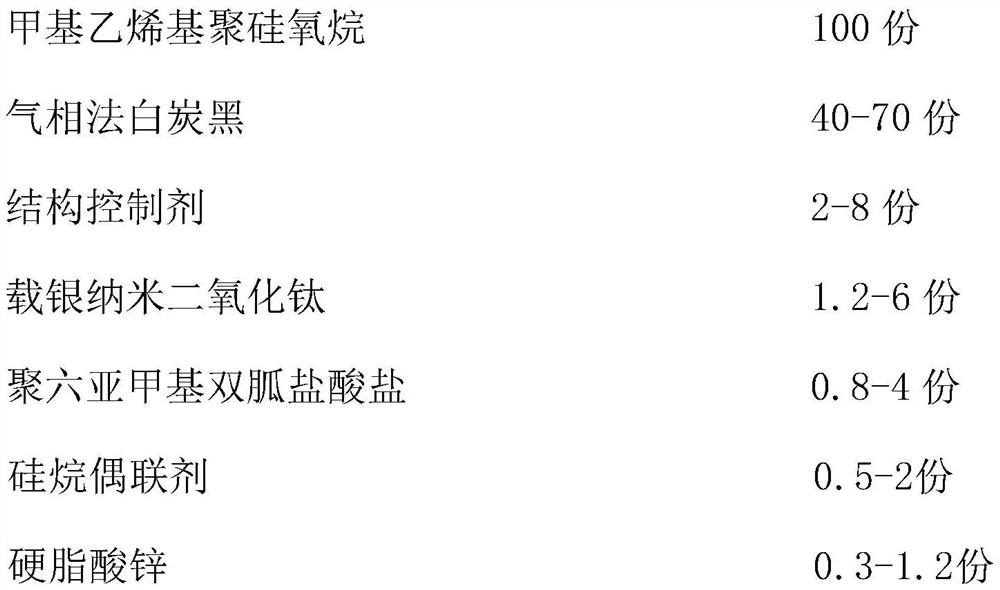

Method used

Image

Examples

Embodiment 1

[0019] In the kneader, add 100 parts of vinyl molar percentages and be 0.10% methyl vinyl polysiloxane and 0.3 part of zinc stearate with a molecular weight of 600,000, stir for 5 minutes; then 40 parts of fumed white carbon black, 2 1 part of hydroxyl silicone oil, added in 4 times, fully stirred after each addition; then 1.2 parts of silver-loaded nano-titanium dioxide, 0.8 parts of polyhexamethylene biguanide hydrochloride and 0.25 parts of KH-151 and KH-560 were mixed The paste, after kneading and molding, is heated to 150°C and kneaded for 1 hour, kept at the temperature and evacuated for 0.5 hours, cooled to below 80°C with cooling water and discharged, cooled to room temperature and filtered to obtain a silicone rubber mix.

[0020] Add 1.5% bis-penta-curing agent evenly into the rubber mixture with an open mill, weigh it, place it in a mold for vulcanization, and vulcanize at 175°C for 5 minutes.

Embodiment 2

[0022] In the kneader, add 100 parts of vinyl molar percentages and be 0.12% methyl vinyl polysiloxane and 0.3 part of zinc stearate with a molecular weight of 600,000, stir for 5 minutes; then 50 parts of fumed white carbon black, 3 1 part of hydroxy silicone oil, added in 5 times, fully stirred after each addition; then added 2.4 parts of silver-loaded nano-titanium dioxide, 1.6 parts of polyhexamethylene biguanide hydrochloride and 0.5 parts of KH-151 and KH-560. The paste, after kneading and molding, is heated to 150°C and kneaded for 1.5 hours, kept at the temperature for 40 minutes under vacuum and heated, cooled to below 80°C with cooling water and discharged, cooled to room temperature and filtered to obtain silicone rubber mix.

[0023] Add 1.5% bis-penta-curing agent evenly into the rubber mixture with an open mill, weigh it, place it in a mold for vulcanization, and vulcanize at 175°C for 5 minutes.

Embodiment 3

[0025] Add 100 parts of vinyl polysiloxane and 0.3 part of zinc stearate with 0.16% molecular weight of 650,000 in molar percentage in the kneader, and stir for 5 minutes; then 70 parts of fumed white carbon black, 5 1 part of hydroxyl silicone oil, added in 6 times, fully stirred after each addition; then 3 parts of silver-loaded nano-titanium dioxide, 2 parts of polyhexamethylene biguanide hydrochloride and 0.5 parts of KH-151 and KH-560 were mixed. After the paste is kneaded and shaped, heat up to 150°C and knead for 1 hour, keep the temperature and heat for 15 minutes under vacuum, pass cooling water to cool down to below 80°C and discharge, cool to room temperature and filter to obtain silicone rubber mix.

[0026] Add 1.2% DCP vulcanizing agent evenly into the mixed rubber with an open mill, place it in a mold for vulcanization after weighing, and vulcanize at 160°C for 5 minutes.

[0027] The mechanical and physical properties and antibacterial effect data of the antiba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com