High-functionality polyether polyol and preparation method thereof

A polyether polyol and high-functionality technology, which is applied in the field of polyether polyol preparation, can solve the problems of difficult direct reaction, low reaction rate, and potential safety hazards, so as to prevent Maillard reaction and avoid solid residues , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

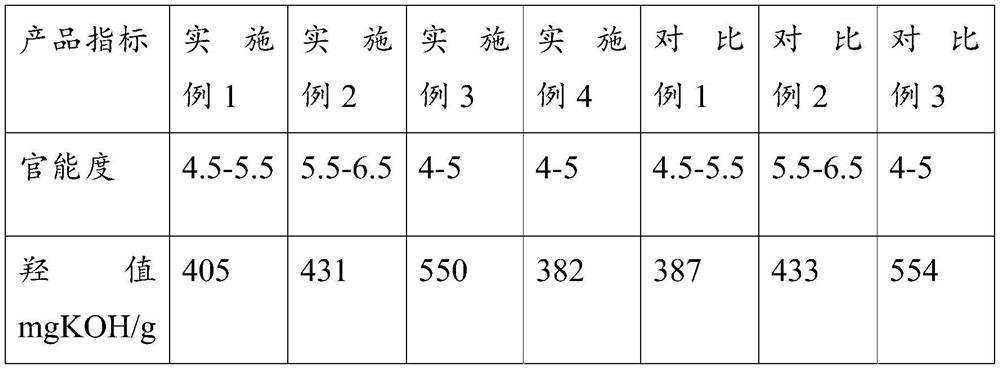

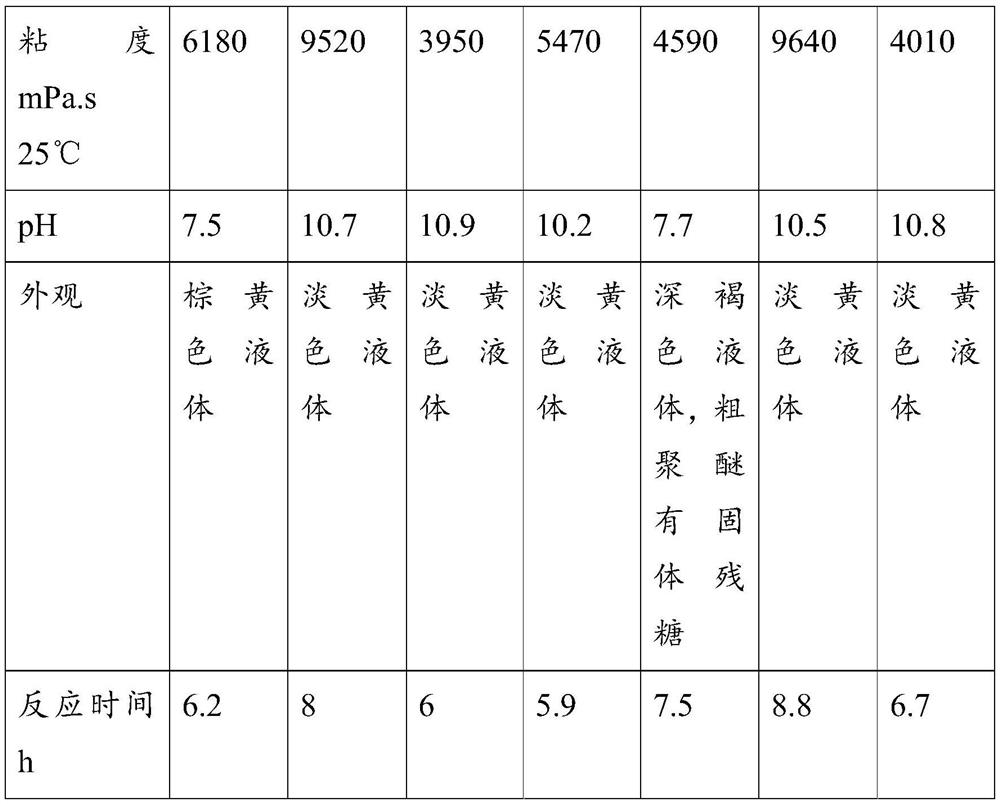

Examples

Embodiment 1

[0047] In a 5L stainless steel autoclave (that is, a reaction kettle) equipped with a stirrer, a heating temperature control device, a cooling device, and a pressure sensor, add 685 g of sucrose, 80 g of glycerin, 20 g of water, 600 g of polyether polyol A, and 6 g of potassium hydroxide 1. N-methylimidazole 1g, start stirring, mix the reaction materials evenly, replace nitrogen 5 times, and vacuumize until the pressure is -0.09MPa;

[0048] Add 4 g of N-methylimidazole into propylene oxide, and mix evenly under nitrogen atmosphere to obtain propylene oxide material, which is set aside;

[0049] When the temperature of the reaction kettle rises to 100°C, start to add propylene oxide material dropwise, control the reaction temperature to 120°C, and control the pressure within 0.4MPa. After adding 2030g of propylene oxide dropwise, the feeding is completed, and it is matured at 120°C. Until the pressure remains constant within 10 minutes, then vacuumize to obtain the crude polye...

Embodiment 2

[0052] In a 5L stainless steel autoclave (that is, a reaction kettle) equipped with a stirrer, a heating temperature control device, a cooling device, and a pressure sensor, add 550 g of sorbitol, 530 g of polyether polyol B, and N,N-dimethylcyclohexane Amine 7.9g, start stirring, mix the reaction materials evenly, nitrogen replacement 5 times, vacuumize until the pressure is -0.09MPa;

[0053] Add 5.7 g of N,N-dimethylcyclohexylamine into propylene oxide, mix evenly under nitrogen atmosphere to obtain propylene oxide material, set aside;

[0054] When the temperature of the reaction kettle rises to 90°C, start to add the propylene oxide material dropwise, control the reaction temperature to 115°C, and control the pressure within 0.4MPa, after adding 1837g of propylene oxide dropwise, the feeding is completed, and it is matured at 120°C. Until the pressure remains constant within 10 minutes, the polyether polyol product is obtained by degassing.

[0055] The synthesized polye...

Embodiment 3

[0057] In a 5L stainless steel autoclave (that is, a reaction kettle) equipped with a stirrer, a heating temperature control device, a cooling device, and a pressure sensor, add 707 g of pentaerythritol, 77 g of polyether polyol C, and 3.5 g of N,N-dimethylcyclohexylamine g, nitrogen replacement 5 times, vacuumize to -0.09MPa, start stirring, and mix the reaction materials evenly;

[0058] Add 5.3 g of triethylamine into propylene oxide, and mix evenly under nitrogen atmosphere to obtain propylene oxide material, which is set aside;

[0059] When the temperature of the reaction kettle rises to 90°C, start to add the propylene oxide material dropwise, control the reaction temperature to 110°C, and control the pressure within 0.35MPa, add 1434g of propylene oxide dropwise and finish feeding, and mature at 115°C. Until the pressure remains constant within 10 minutes, the polyether polyol product is obtained by degassing.

[0060] The synthesized polyether polyol indicators are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com