Concrete air entraining agent as well as preparation and application thereof

An air-entraining agent and concrete technology, which is applied in the field of concrete air-entraining agents, can solve the problems of weakening the freeze-thaw resistance of concrete, the air-entraining performance of the air-entraining agent being reduced, and the life of the bubbles being shortened, so as to achieve high stability of the bubble structure, High foaming efficiency and improved air entrainment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

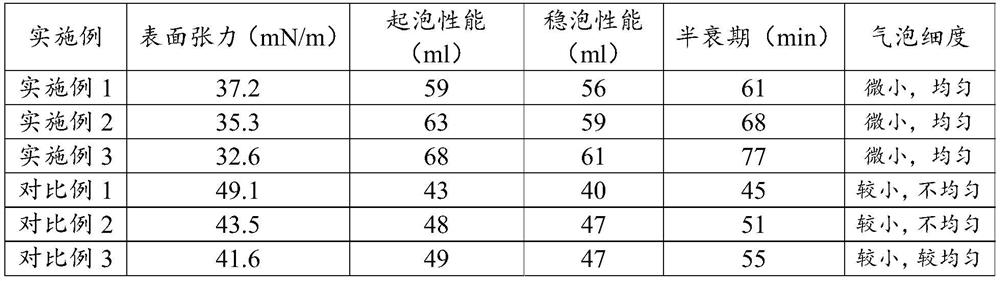

Examples

Embodiment 1

[0026] Weigh 30 parts of triterpene saponins, 40 parts of sodium lauryl sulfate, 5 parts of silicone polyether emulsion, 2 parts of polyethoxy propoxylated alcohol ether, 1 part of polymaleic acid, 10 parts of hydroxyethyl Cellulose, 8 parts of nano silica, 500 parts of deionized water.

[0027] Put triterpene saponin, sodium lauryl sulfate, deionized water and silicone resin polyether emulsion into a 100ml beaker, stir (400 rpm) for 1 minute, then add polymaleic acid, polyethoxypropyl Oxylated alcohol ether, hydroxyethyl cellulose and nano-reinforced particles, and stirred at high speed (400 rpm) for 2 minutes after each addition.

[0028] Pour clean water into the constant temperature digital display water bath, and set the temperature to 45°C with the dial; when the digital display of the water bath reaches the set temperature, place the beaker containing the mixture in the water bath and stir with a glass rod while heating in the water bath.

[0029] After 5 minutes, the ...

Embodiment 2

[0031]Weigh 30 parts of modified rosin thermal polymer, 50 parts of sodium lauryl sulfate, 7 parts of silicone resin polyether emulsion, 4 parts of polyethoxy propoxylated alcohol ether, 15 parts of hydroxyethyl cellulose, 11 parts Parts of nano calcium carbonate, 500 parts of deionized water.

[0032] Put the weighed modified rosin thermal polymer, sodium lauryl sulfate, deionized water and silicone resin polyether emulsion into a 100ml beaker, stir (400 rpm) for 1 minute, and then add polyethylene oxide propoxylated alcohol ether, hydroxyethyl cellulose and nano-reinforced particles, and stirred (400 rpm) for 2 minutes after each addition.

[0033] Pour clean water into the constant temperature digital display water bath, and set the temperature to 45°C with the dial; when the digital display of the water bath reaches the set temperature, place the beaker containing the mixture in the water bath and stir with a glass rod while heating in the water bath.

[0034] After 5 min...

Embodiment 3

[0036] Weigh 20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 30 parts of sodium dodecylbenzenesulfonate, 40 parts of sodium dodecyl sulfate, 5 parts of silicone resin polyether emulsion, 5 parts of polyacrylamide, 5 parts of poly Maleic acid, 20 parts of hydroxyethyl cellulose, 10 parts of nano silicon dioxide, 5 parts of nano calcium carbonate, 500 parts of deionized water.

[0037] Put fatty alcohol polyoxyethylene ether sodium sulfate, sodium dodecylbenzenesulfonate, sodium dodecylsulfate, deionized water and silicone resin polyether emulsion into a 100ml beaker, stir (400 rpm) for 1 minute Finally, polyacrylamide, polymaleic acid, hydroxyethyl cellulose, and nano-reinforced particles were added in sequence, and stirred (400 rpm) for 2 minutes after each addition.

[0038] Pour clean water into the constant temperature digital display water bath, and set the temperature to 45°C with the dial; when the digital display of the water bath reaches the set tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com