High-load crystal nucleus solid-liquid separation device and method

A solid-liquid separation, high-load technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the loss of small particles, the reduction of treatment efficiency, and the formation rate of large particles Low and other problems, to achieve the effect of increasing the rising flow rate, improving efficiency, and reducing the moisture content of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

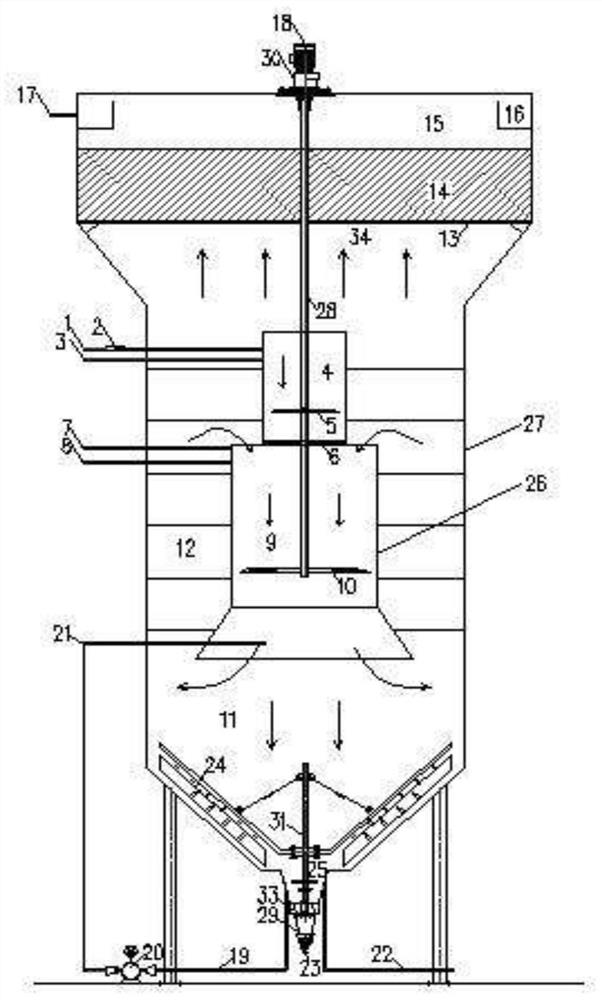

[0038] Such as figure 1As shown, a high-load crystal nucleus solid-liquid separation device includes an inner shell 26 and an outer shell 27, and the inner shell 26 is sequentially provided with a granulation zone 4 and a flocculation zone 9, and the outer shell 27 There are clear water area 15, honeycomb packing 14, honeycomb packing sedimentation area 34, separation area 12, concentration area 11, and mud collection area 25 in sequence.

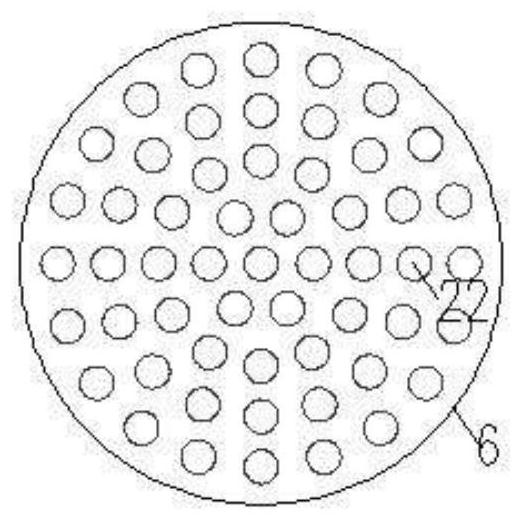

[0039] The granulation zone 4 is provided with a water inlet pipe 1, a pipeline mixer 2, a seeding tube 3, an agitator 5, and a water distributor 6, and crystallizes and granulates the demineralized water. The pipeline mixer 2 is provided with an alkaline medicament dosing port for dosing and mixing the demineralized water. The stirrer 5 is provided with stirring blades. The flocculation zone 9 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com