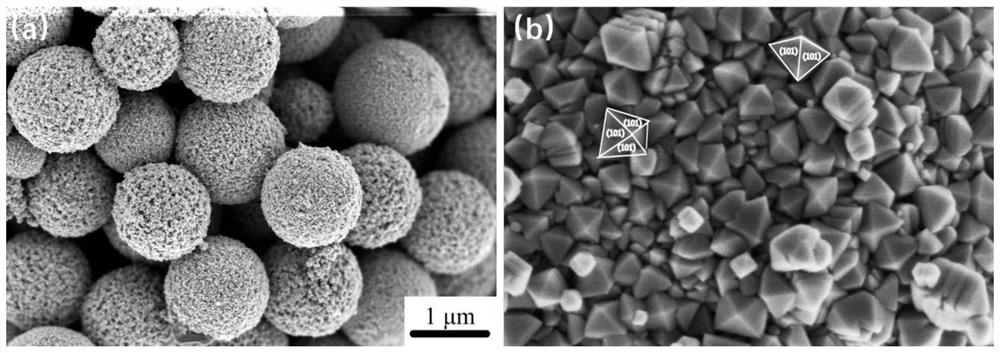

A kind of titanium dioxide mesoporous microsphere with high-energy crystal surface exposure and preparation method thereof

A titanium dioxide and mesoporous technology, applied in the field of photocatalytic materials, can solve the problems of insufficient mesoporous structure, complex preparation system, introduction of impurity environment, etc., to increase impurities and treatment process, simple preparation system, and good monodispersity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Add 0.25 mL of NaCl solution (0.05 mol / L) to 100 mL of ethanol in a cold bath at -40°C, and stir at a speed of 500 r / min for 30 min to mix well to obtain a mixed solution.

[0055] (2) 4 mL of tetrabutyl titanate was added to the above mixed solution and continued to be stirred for 10 h at a speed of 500 r / min in a -40° C. cold bath to obtain suspension A.

[0056] (3) The above-mentioned suspension A was centrifuged at 5000 r / min to collect the precipitated product and washed with alcohol for 3 times and water for 3 times to obtain a white product, and then freeze-dried the white product at -80 °C for 2 h to obtain the precursor of titanium dioxide mesoporous microspheres .

[0057] (4) adding the prepared titanium dioxide mesoporous microsphere precursor to a mixture of 70 mL of ethanol and 10 mL of deionized water and stirring to form suspension B;

[0058] (5) Place the above-mentioned suspension B in a 100 mL stainless steel reaction kettle with a polytetraflu...

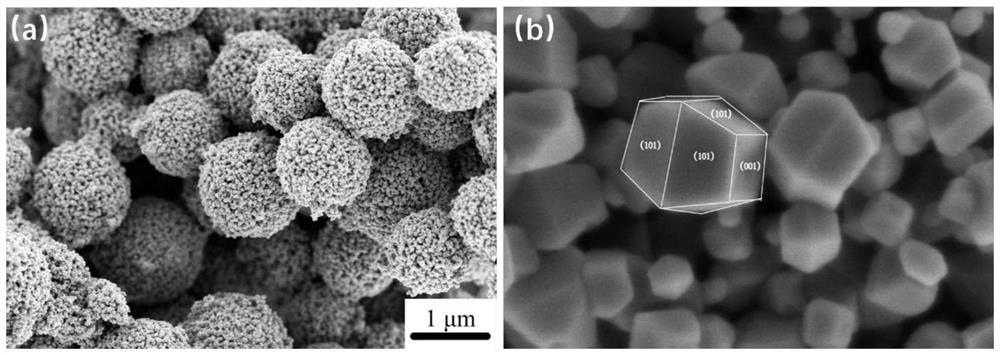

Embodiment 2

[0061] (1) Add 0.5 mL of KCl solution (0.001 mol / L) to 100 mL of butanol in a cold bath at -25°C, and stir at a speed of 100 r / min for 15 min to mix well to obtain a mixed solution.

[0062] (2) 1 mL of titanium isopropoxide was added to the above mixed solution and continued to be stirred at a speed of 100 r / min in a -25° C. cold bath for 4 h to react to obtain suspension A.

[0063] (3) The above-mentioned suspension A was centrifuged at 2000 r / min to collect the precipitated product and washed with alcohol for 3 times and water for 3 times to obtain a white product, and then freeze-dried the white product at -10°C for 12 h to obtain titanium dioxide mesoporous microspheres.

[0064] (4) adding the prepared titanium dioxide mesoporous microsphere precursor to a mixture of 50 mL of isopropanol and 30 mL of deionized water and stirring to form suspension B;

[0065] (5) Place the above-mentioned suspension B in a 100 mL stainless steel reaction kettle with a polytetrafluoroeth...

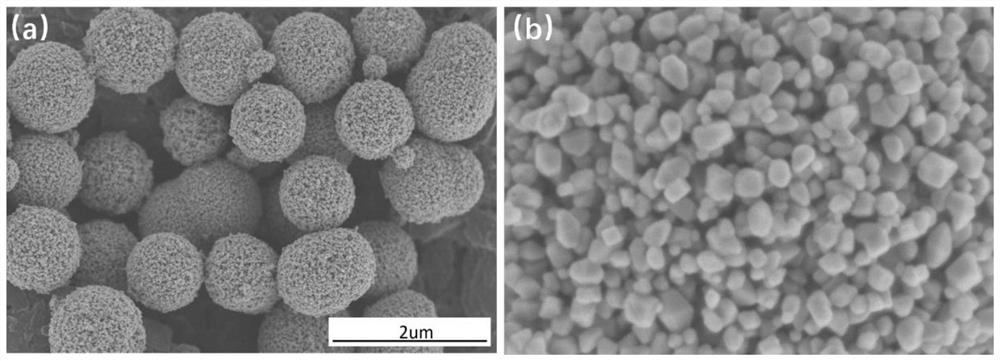

Embodiment 3

[0067] (1) Put 1 mL of KNO in a cold bath at -10°C 3 with Na 2 SO 4 mixed solution (KNO 3 with Na 2 SO 4 The concentration was 0.1 mol / L) into 100 mL of ethanol and propanol mixed solution, and stirred at a rotational speed of 1000 r / min for 240 min to mix uniformly to obtain a mixed solution.

[0068] (2) 10 mL of a mixture of tetrabutyl titanate and titanium isopropoxide was added to the above mixed solution, and the mixture was continued to be stirred at 1000 r / min for 6 h in a -10°C cooling bath to obtain suspension A.

[0069] (3) The above-mentioned suspension A was centrifuged at 4000 r / min to collect the precipitated product and washed with alcohol for 3 times and water for 3 times to obtain a white product, and then freeze-dried the white product at -50°C for 6 h to obtain titanium dioxide mesoporous microspheres.

[0070] (4) adding the prepared titanium dioxide mesoporous microsphere precursor to 80 mL of deionized water and stirring to form suspension B;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com