Intelligent self-inspection production line for automatic unpacking, stacking, loading and unloading of machining tool head cavity

A production line and cutter head technology, applied in the field of intelligent processing production line, can solve the problems of troublesome detection process, uncompact production line structure, long production line waiting time, etc., to reduce the frequency of manual intervention, reduce manual intervention time, and reduce production line Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

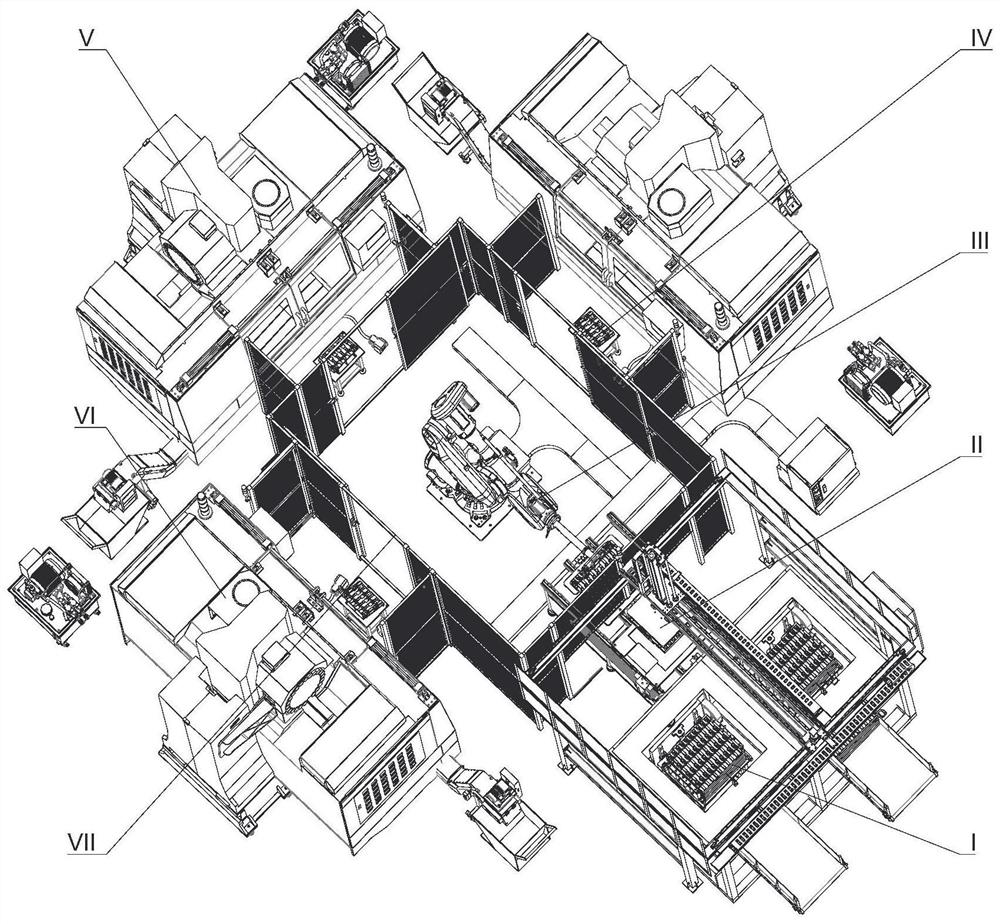

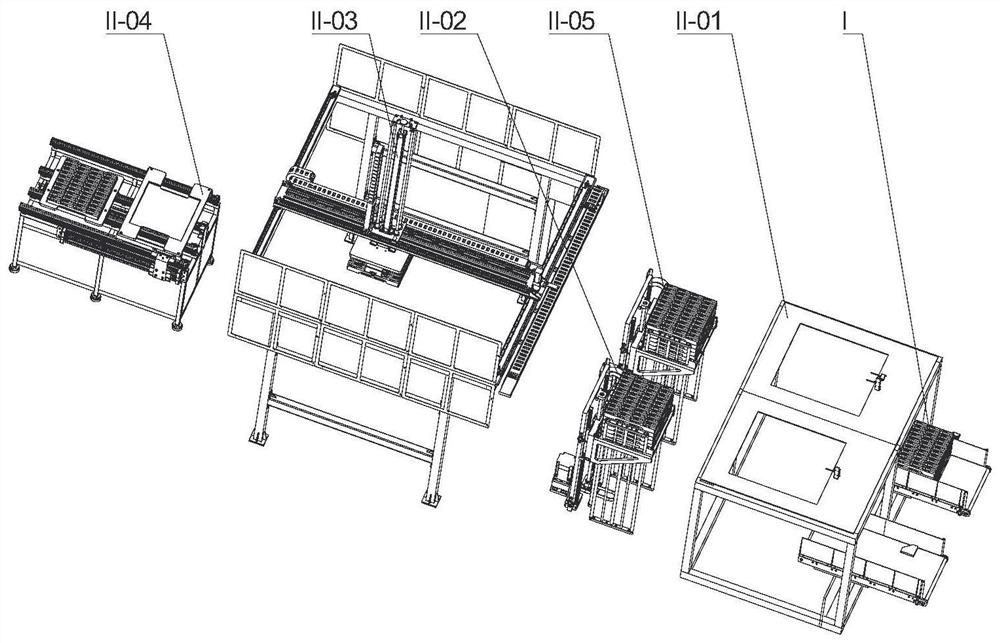

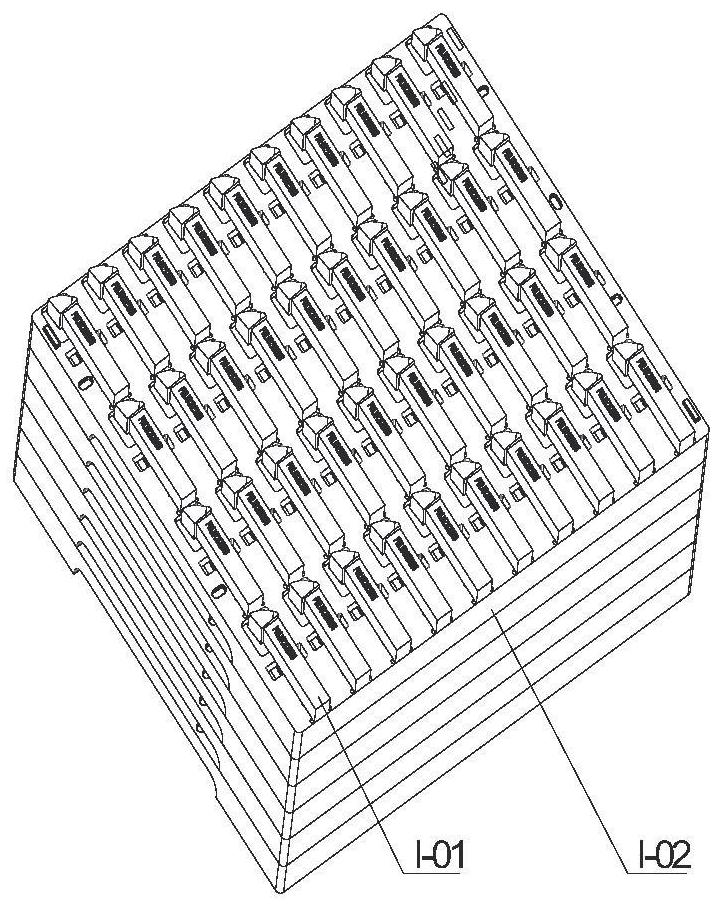

Embodiment 1

[0115] This embodiment provides an intelligent self-inspection production line for automatic unstacking, stacking, and loading and unloading for processing turning tool head cavity, such as figure 1 As shown in the figure, it includes the stacking assembly I of the material tray, the material management system II, the robot III, the transfer station IV, the machining center V, the tool on-machine detection system VI, and the protective fence VII. The protective fence VII is set on the outside of the robot III, and the material management system II and a plurality of machining centers V are evenly arranged in the circumferential direction with the robot III as the center. The tool on-machine inspection system VI is installed on the top of the machining center V. A transfer station IV is set between each machining center V and the protective fence VII. In this embodiment, three machining centers V are provided. The straight-line distances between the robot III and each transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com