Bolt dismounting and mounting device and dismounting and mounting mode

A bolt disassembly and assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the operator is difficult to reach the bolt, arm length, high operating experience requirements, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

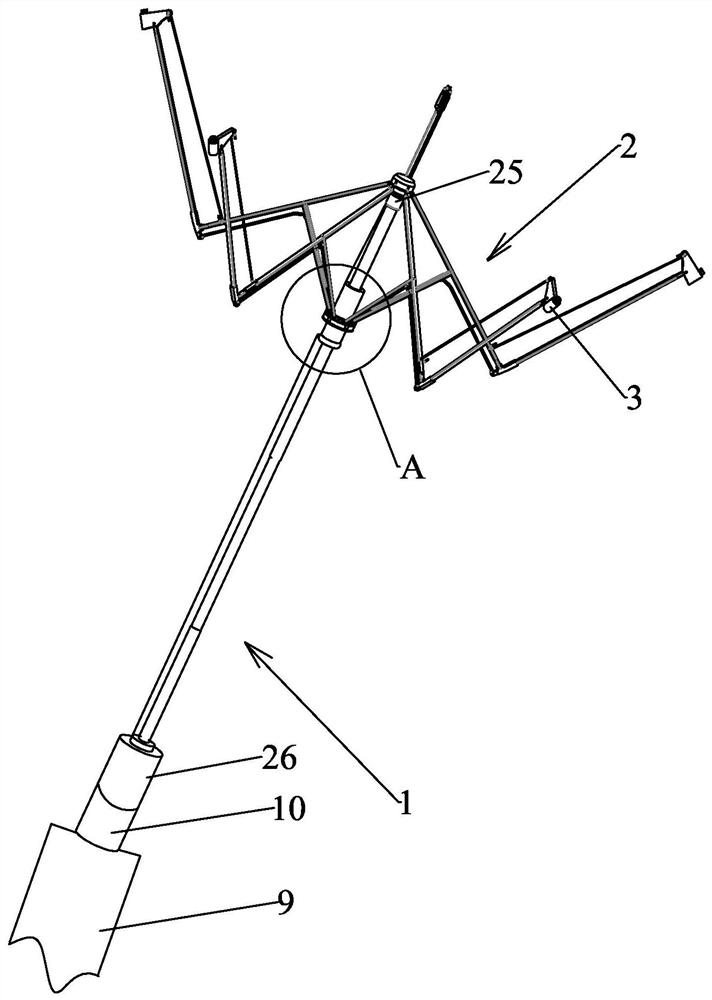

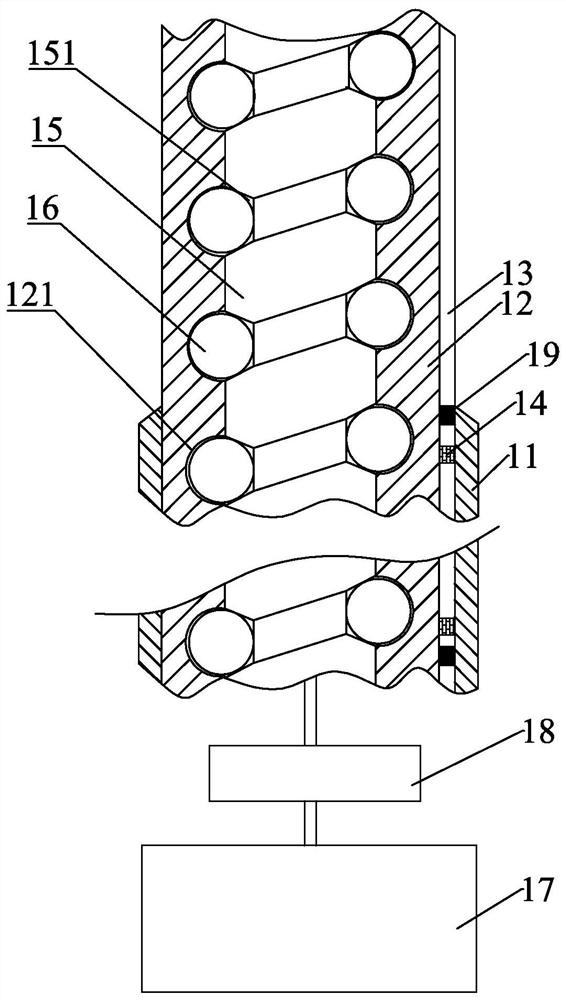

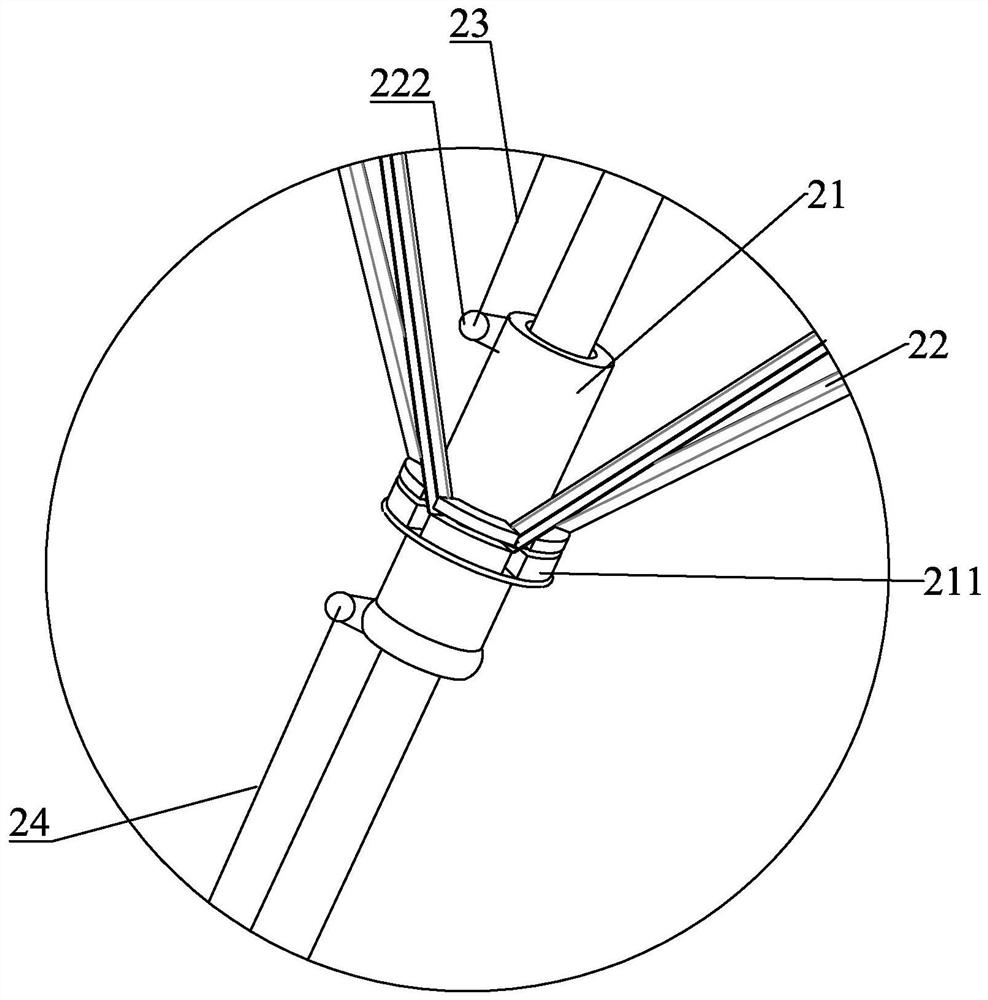

[0032] What the present invention discloses is a kind of bolt dismounting device, such as Figure 1-9 As shown, it is a preferred embodiment of the present invention, such as figure 1 , Figure 7 with Figure 8 As shown, in this embodiment, in order to meet the needs of bolt disassembly and assembly in the narrow and long space 91, a telescopic rod 1 is designed, and in order to meet the disassembly and assembly operations of multiple bolts at the same time, the bolt disassembly device includes a plurality of electric disassembly and assembly rotation Block 3, the electric disassembly and assembly rotating block 3 is a conventional technology in the field of bolt electric locking. It generally drives the disassembly and assembly rotation block that is consistent with the shape of the bolt head by setting a motor to rotate, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com