Composite molecular sieve and catalyst for hydroisomerization dewaxing reaction, preparation methods and applications thereof

A technology of hydroisomerization dewaxing and composite molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. problems such as low rate, to achieve the effects of lowering freezing point and cloud point, high activity and selectivity, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

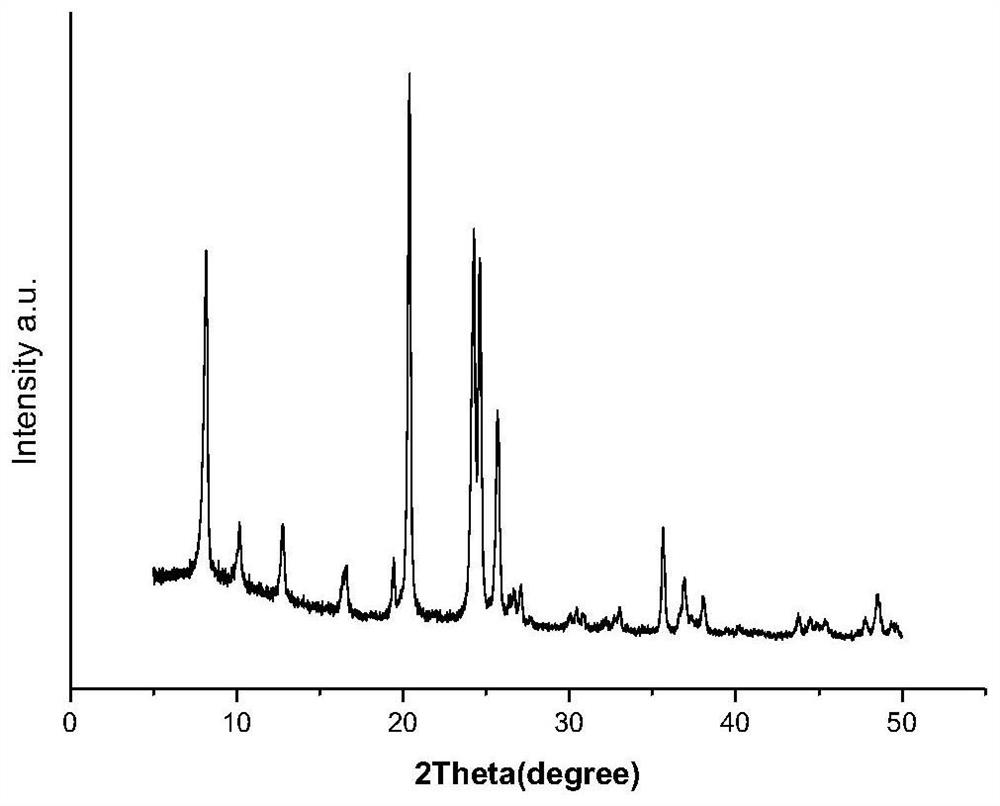

[0059] Mix 5.15g of aluminum sulfate, 284g of deionized water and 4.9g of potassium hydroxide, stir well, then add 21.3g of hexamethylenediamine and continue stirring; add 120.8g of silica sol (30%SiO2, 70%H2O) into the above mixture Continue to stir for 30 minutes, then heat and stir in a high-pressure reactor, and crystallize at 160°C for 34 hours; wash and filter the product until the filtrate is neutral, and dry the filter cake at 120°C for 6 hours to obtain ZSM-22 Original powder. Some samples were taken for X-ray diffraction analysis. figure 1 The wide-angle XRD spectrum of the sample shows that the ZSM-22 molecular sieve was synthesized.

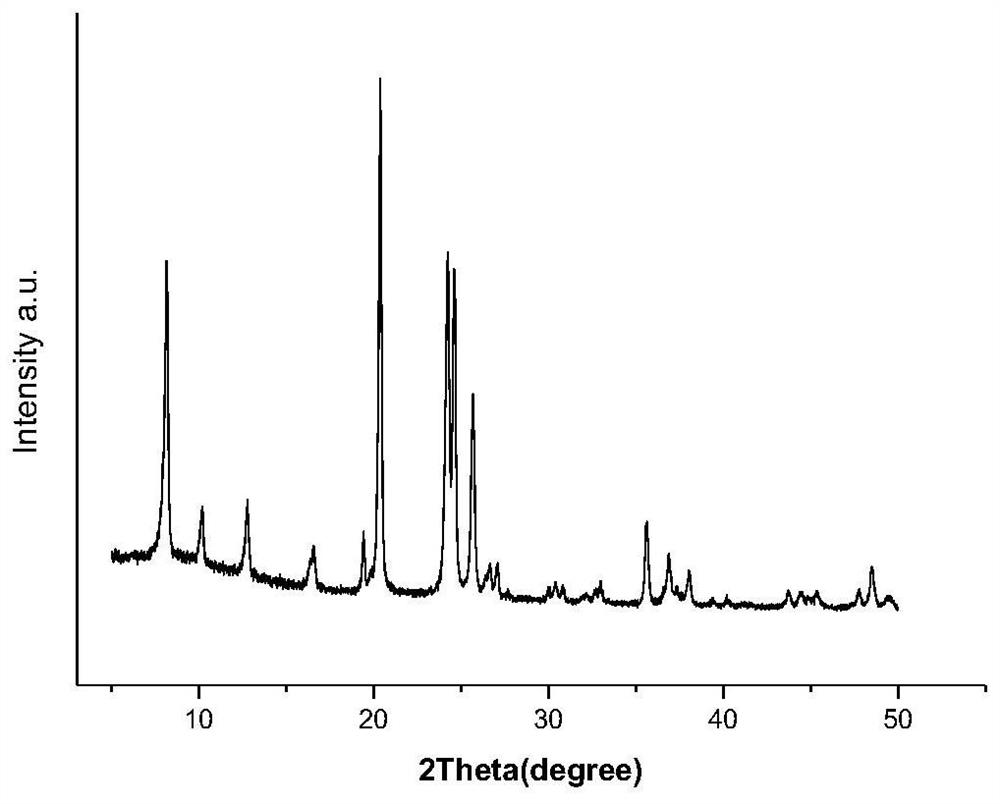

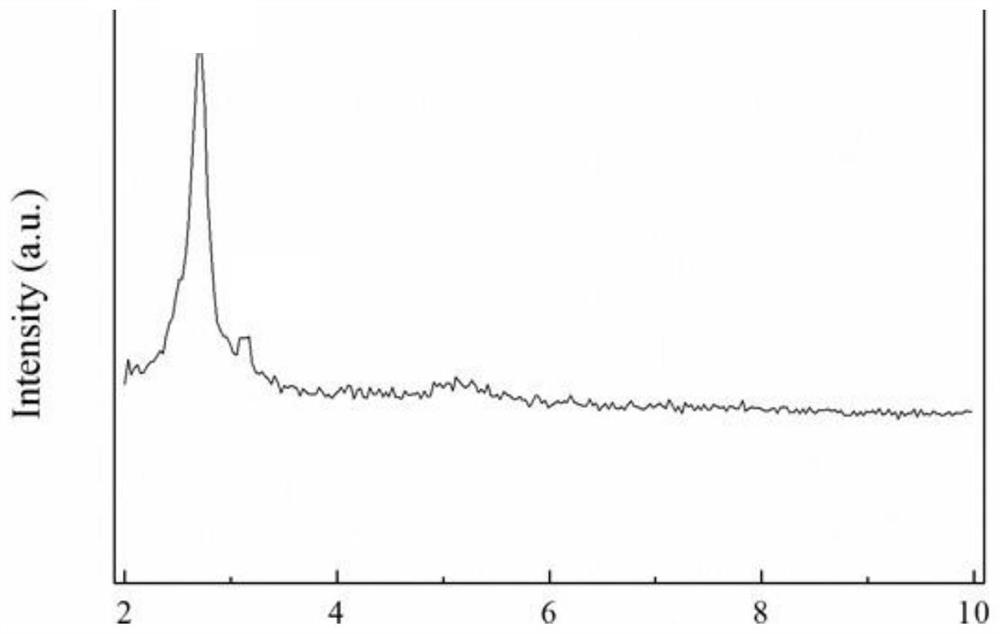

[0060] Then add 10.65g cetyltrimethylammonium bromide, 650g deionized water, 30.05g silica sol, 1.05g aluminum sulfate to the above-mentioned ZSM-22 former powder and continue to stir for 30min, after adding a certain amount of sodium hydroxide Adjust the pH to 10-11, then heat and stir in an autoclave, and crystallize at 160°C for ...

Embodiment 2

[0070] Mix 10.05g of aluminum sulfate, 410g of deionized water and 6.7g of sodium hydroxide, stir evenly, then add 35.8g of hexamethylenediamine and continue stirring; add 200.9g of silica sol (30% SiO2, 70% H2O) into the above mixture Continue to stir for 30 minutes, then heat and stir in a high-pressure reactor, and crystallize at 160°C for 34 hours; wash and filter the product until the filtrate is neutral, and dry the filter cake at 120°C for 6 hours to obtain ZSM-22 Original powder.

[0071] Then add 18.45g cetyltrimethylammonium bromide, 890g deionized water, 35.15g silica sol, 2.67g aluminum sulfate to the above-mentioned ZSM-22 former powder and continue to stir for 30min, after adding a certain amount of sodium hydroxide Adjust the pH to 10-11, then heat and stir in an autoclave, and crystallize at 160°C for 34 hours; wash and filter the product until the filtrate is neutral, and dry the filter cake at 120°C for 6 hours to obtain ZSM-22 / MCM-48 original powder.

[00...

Embodiment 3

[0078] Mix 5.15g of aluminum sulfate, 284g of deionized water and 4.9g of potassium hydroxide, stir well, then add 21.3g of hexamethylenediamine and continue stirring; add 120.8g of silica sol (30%SiO2, 70%H2O) into the above mixture Continue to stir for 30 minutes, then heat and stir in a high-pressure reactor, and crystallize at 160°C for 34 hours; wash and filter the product until the filtrate is neutral, and dry the filter cake at 120°C for 6 hours to obtain ZSM-22 Original powder.

[0079]Then add 12.35g of cetyltrimethylammonium bromide, 750g of deionized water, 25.15g of silica sol, 1.56g of aluminum sulfate and continue stirring for 30min, then add a certain amount of sodium hydroxide to adjust the pH to 10-11, Then put it into a high-pressure reactor to heat and stir, and crystallize at 160°C for 34h; wash and filter the product until the filtrate is neutral, and dry the filter cake at 120°C for 6h to obtain ZSM-22 / MCM-48 Original powder.

[0080] With 0.4mol / L NH4S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com