A flue gas treatment device based on low temperature gas separation

A technology for flue gas treatment and low-temperature gas, which is applied in the direction of gas treatment, use of liquid separation agent, separation method, etc., can solve the problems of easy corrosion of equipment, white smoke pollution, high energy consumption, etc., and achieve the reduction of comprehensive operating costs and chemical Corrosion, the effect of reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

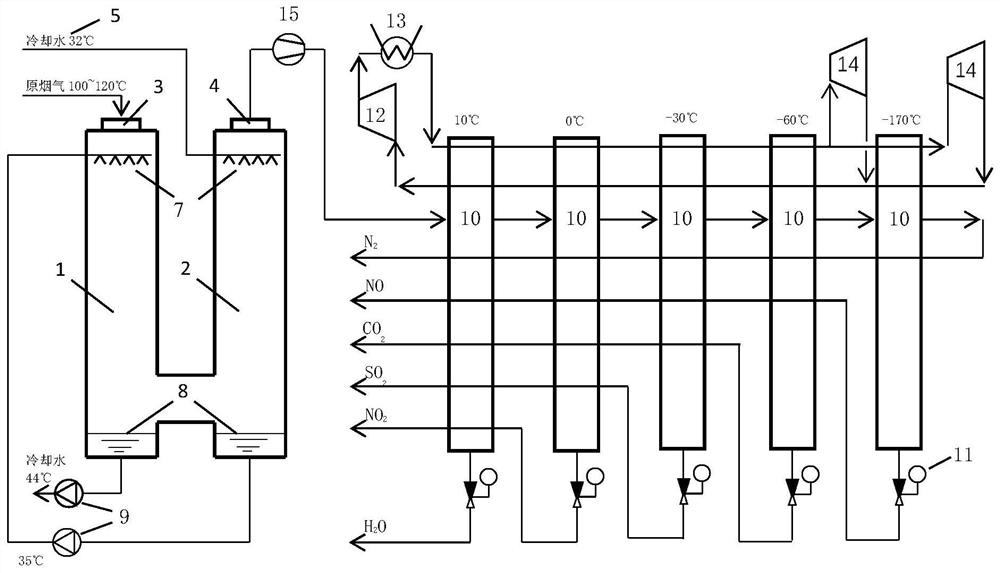

[0016] Taking the flue gas produced by burning coal as an example, the flue gas raw gas contains H 2 O, NO 2 , SO 2 , CO 2 , NO and N 2 , a total of 6 kinds of gas components. The present invention will be further described below with reference to the accompanying drawings for the above-mentioned specific problems.

[0017] like figure 1 As shown, the flue gas treatment device based on low temperature gas separation includes: a flue gas scrubbing device, a gas condensation separation device and a refrigeration cycle device; the flue gas scrubbing device includes: a first cooling tower 1, a second cooling tower 2, Flue gas inlet 3, flue gas outlet 4, cooling water inlet 5, cooling water outlet 6; the gas condensation and separation device includes: a partial condenser 10 and a steam trap 11; the refrigeration cycle device includes: a compressor 12, a cooler 13 and expander 14.

[0018] When processing flue gas, the raw gas enters the first cooling tower 1 through the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com