A preparation method of activated carbon for treating automobile exhaust in expressway tunnels

A technology for automobile exhaust and highways, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of increased resistance of activated carbon filter devices, failure to meet the ventilation requirements of tunnels, and decreased gas flow, etc., to achieve tar The effect of increasing the content, increasing the effective service life, and maintaining the constant adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Use anthracite Taixi coal with an ash content of 3% as the main material, and pass the washed clean coal through the Raymond milling process to obtain coal powder with a mesh size greater than 200 mesh;

[0027] Step 2: According to the ratio of mass fractions: take 38 parts, 40 parts, 42.5 parts, 45 parts, 48 parts of tar, respectively, and fully mix and stir with 100 parts of coal powder and 4 parts of water prepared in S1 step to obtain five parts of mixture , using a four-axis hydraulic press with a cylinder diameter of 500mm and a mold to press the mixture into five kinds of 9mm diameter carbon bars with different coal tar ratios, and the pressure of the hydraulic press is 11.5MPa;

[0028] Step 3: cutting the charcoal rods prepared in step S2 into cylindrical charcoal rods with a length of 14 mm;

[0029] Step 4: Cool the charcoal rods prepared in step S3 for at least 36 hours, so as to fully eliminate the internal stress;

[0030] Step 5: Gradually hea...

Embodiment 2

[0036] Step 1: Use anthracite Taixi coal with an ash content of 3% as the main material, and pass the washed clean coal through the Raymond milling process to obtain coal powder with a mesh size greater than 200 mesh;

[0037] Step 2: According to the ratio of mass fractions: take 42.5 parts of tar, 100 parts of coal powder prepared in S1 step, and 4 parts of water after fully mixing and stirring to obtain a mixture. Divide the above mixture into 5 equal parts and put them in batches. Put it into the mold, adjust the pressure value of the four-axis hydraulic press with a cylinder diameter of 500mm to 8MPa, 10MPa, 11.5MPa, 13MPa, and 15MPa, and press the mixture into five batches of carbon rods with a diameter of 9mm;

[0038] Step 3: cutting the charcoal rods prepared in step S2 into cylindrical charcoal rods with a length of 14 mm;

[0039] Step 4: Cool the charcoal rods prepared in step S3 for at least 36 hours, so as to fully eliminate the internal stress;

[0040] Step 5:...

Embodiment 3

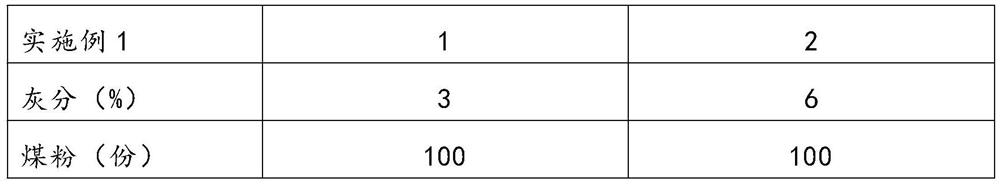

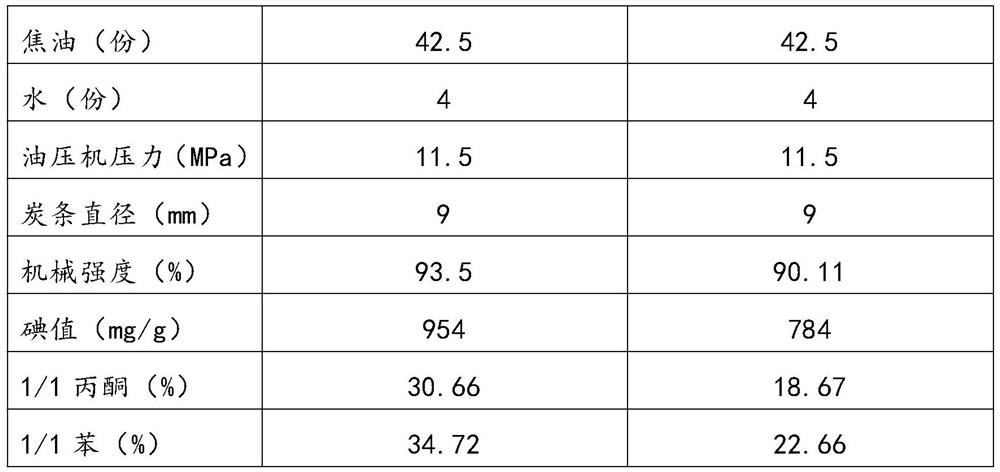

[0046] Step 1: using anthracite Taixi coal with an ash content of 3% and 6% respectively as the main material, and passing the washed clean coal through the Raymond milling process to obtain two types of coal powder with a mesh size greater than 200 mesh;

[0047] According to the ratio of mass fraction: take 100 parts of the ash obtained in the S1 step to be 3% coal powder and 100 parts of the ash obtained in the S1 step to be 6% coal powder, and fully mix and stir with 42.5 parts of tar and 4 parts of water , to obtain two kinds of mixtures, put the above mixtures into the mold in batches, use the cylinder diameter of 500mm four-axis hydraulic press and the mold to press the mixture into two kinds of 9mm diameter carbon strips with different ash content of the main material, and the pressure of the hydraulic press is 11.5MPa ;

[0048] Step 3: cutting the charcoal rods prepared in step S2 into cylindrical charcoal rods with a length of 14 mm;

[0049]Step 4: Cool the charco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com