Method for processing double-effect-orientated-characteristic-ingredient-enriched instant tea

A technology of directional enrichment and processing method, which is applied in the field of deep processing of tea, can solve the problems of low added value in the market, single processing technology, lack of effective control of the dissolution of functional components and taste substances, etc., so as to improve the comprehensive yield of products and fresh taste Cool, high value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

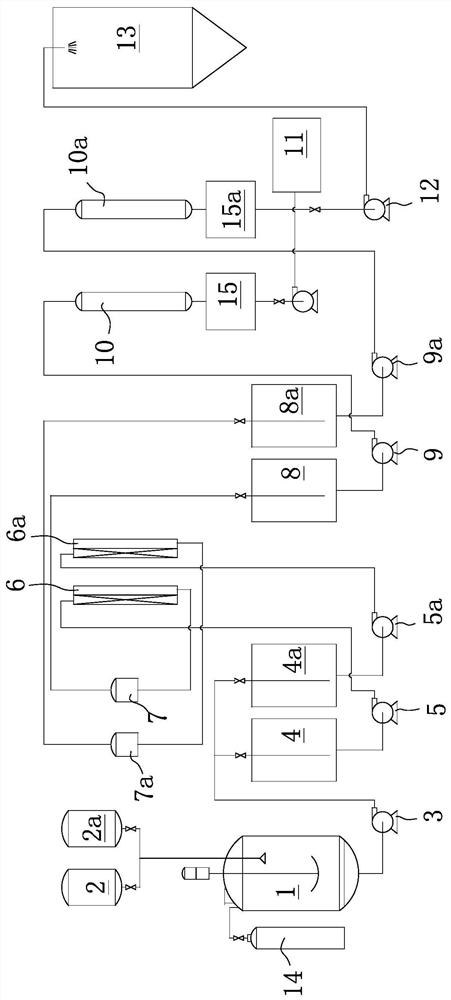

Method used

Image

Examples

Embodiment 2

[0051] An instant tea processing method for double-effect directional enrichment of characteristic components, comprising the following steps:

[0052] 1) Extraction: take green tea, use tea leaves:purified water=1:15 mass ratio, extract at 40°C for 3 hours, obtain extract I and tea dregs after solid-liquid separation, use tea leaves:purified water=1 : Add a solvent to the tea residue at a mass ratio of 6, extract the tea residue for 0.5h at a temperature of 95° C., and obtain extract II after solid-liquid separation;

[0053] 2) Filtration: Cool the extract I and II through a heat exchanger to 10°C and 25°C, respectively, and then filter with a filter membrane with a pore size of 0.3 μm to obtain the filtrate I and II,

[0054] 3) Concentration and drying: Concentrate the filtrate I and filtrate II to concentrations of 15Brix and 15Brix respectively to obtain concentrated liquid I and concentrated liquid II. After the concentrated liquid I is vacuum freeze-dried, instant tea ...

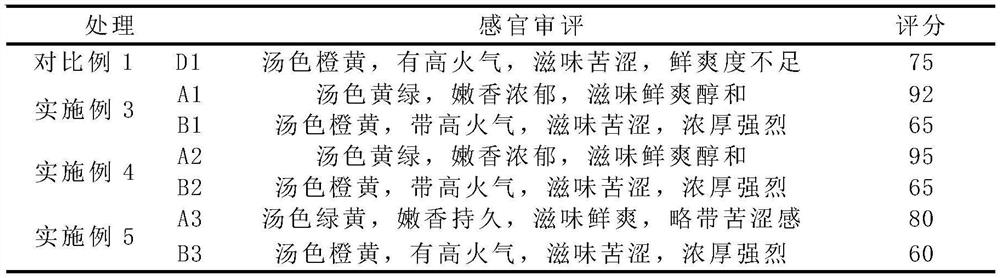

Embodiment 3

[0070] A method for processing instant tea with double-effect directional enrichment of characteristic components. This embodiment adopts the instant tea processing equipment with double-effect directional enrichment of characteristic components provided in Example 2. The specific steps are as follows:

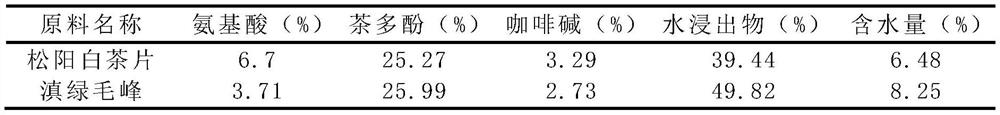

[0071] A. Tea screening: choose Songyang white tea flakes as raw material, which has strong tea aroma, no peculiar smell, and low phenol ammonia ratio.

[0072] B, extraction 1: extraction of tea raw material and purified water for 3 hours at a temperature of 45° C. with a mass ratio of 1: 15, to obtain extraction solution I and tea residue after solid-liquid separation;

[0073] C. Extraction 2: With the mass ratio of tea leaves: purified water = 1:6, the tea dregs are extracted twice for 0.5h at a temperature of 95° C. to obtain extract II; the tea quality here refers to the first extraction The weight of the tea leaves is not the weight of the tea dregs.

[0074] D. Separa...

Embodiment 4

[0078] An instant tea processing method for double-effect directional enrichment of characteristic components, the specific steps are as follows:

[0079] A. Tea screening: choose Songyang white tea flakes as raw material, which has strong tea aroma, no peculiar smell, and low phenol ammonia ratio.

[0080] B, leaching 1: leaching 2.5h at the temperature of 40 ℃ with tea raw material and purified water with the mass ratio of 1: 15, obtain extract I and tea dregs after solid-liquid separation;

[0081] C. Extraction 2: according to the mass ratio of tea leaves: purified water = 1:6, add purified water to the tea residue, and carry out secondary extraction of the tea residue for 0.5h at a temperature of 90° C. to obtain extract II;

[0082] D. Separation and purification: Cool the extract solution I to about 10°C through a plate heat exchanger, cool the extract solution II to about 25°C through a plate heat exchanger, and then filter it with a filter membrane with a pore size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com