Novel food processing device

A food processing device, a new type of technology, applied in the fields of food science, dough forming and slitting combination, dough sheeter/roller/rolling pin, etc., can solve the problem of lack of mass production machinery and heavy labor load of workers , large labor costs and other issues, to achieve the effect of easy cutting operation, uniform thickness, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

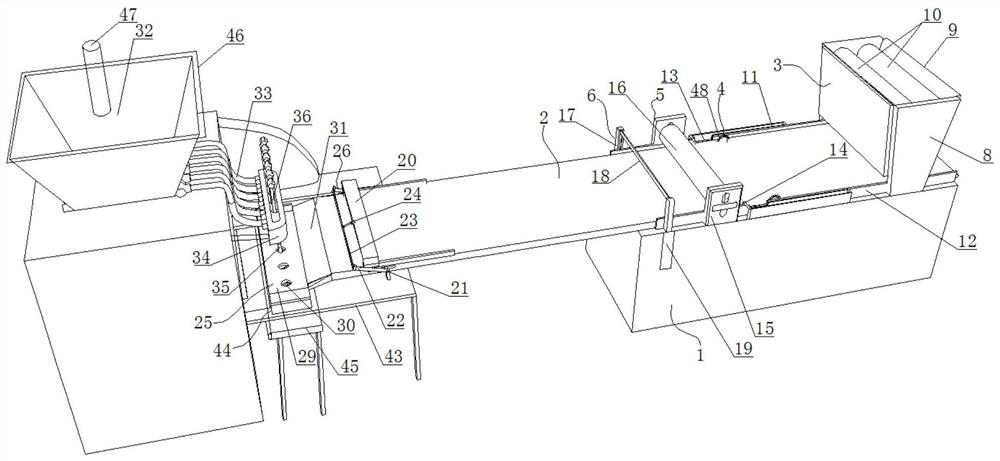

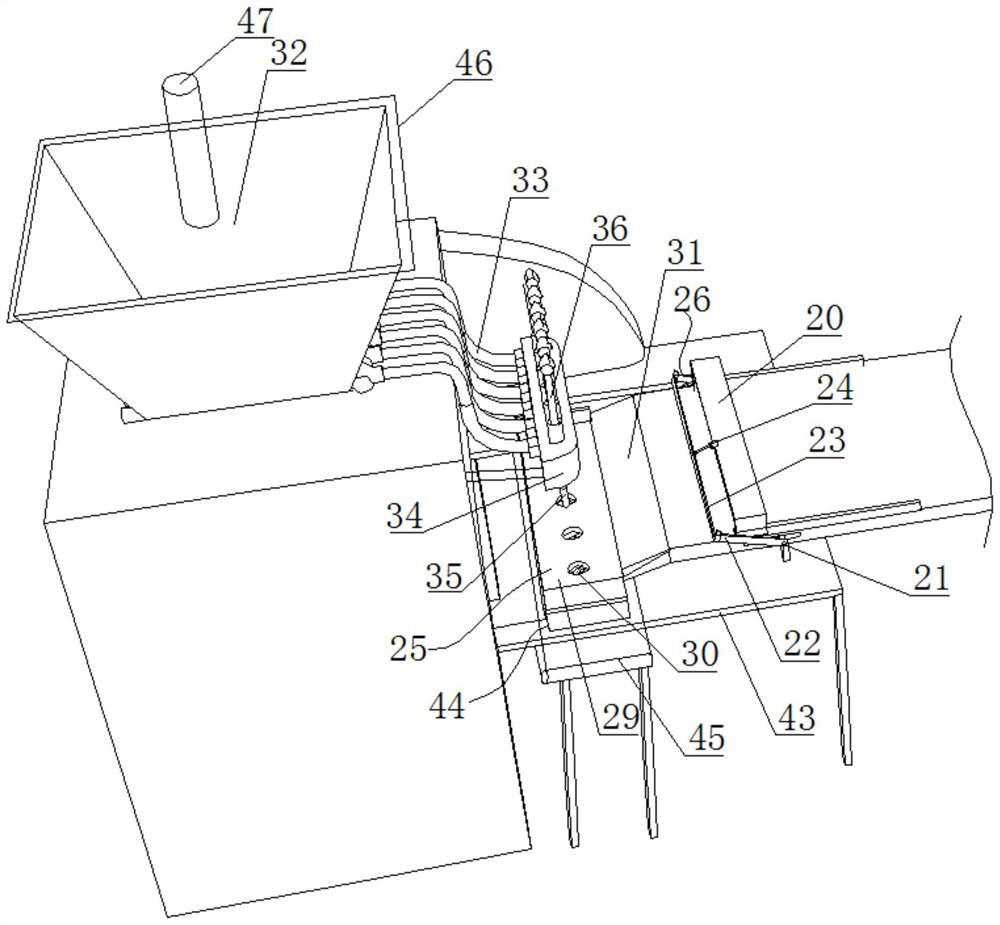

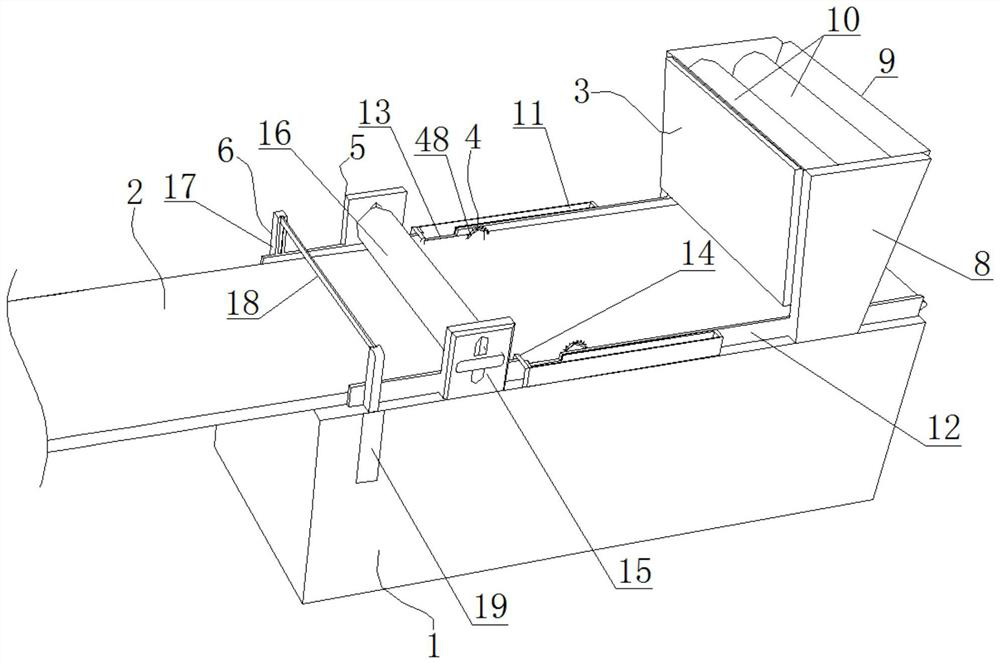

[0028] Such as Figure 1 to Figure 6 As shown, a new type of food processing device includes a frame 1, a belt conveyor A2, a dough pressing mechanism 3, a side cutting mechanism 4, a pressing mechanism 5, a first dividing mechanism 6, a second dividing mechanism 7, a third Split mechanism 26, filling kneading mechanism 25;

[0029] The belt conveyor A2 is installed horizontally on the upper end of the frame 1, and extends in the left and right directions. A pair of side baffles 12 fixedly connected to the upper end of the frame 1 are arranged on the front and rear sides of the belt conveyor A2. The inner surface of the plate 12 is matched with the gap between the front and rear ends of the belt on the belt conveyor A2 to prevent the dough from falling off on the belt conveyor A2;

[0030] Described dough pressing mechanism 3 comprises a pair of support vertical plate A8, lower hopper 9, many pairs of pressing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com