Fluorine-containing sulfonate electrolyte additive, electrolyte containing additive and lithium ion battery

An electrolyte additive and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve problems that cannot be generally achieved, and achieve the effects of suppressing side reactions, improving stability, and ensuring excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

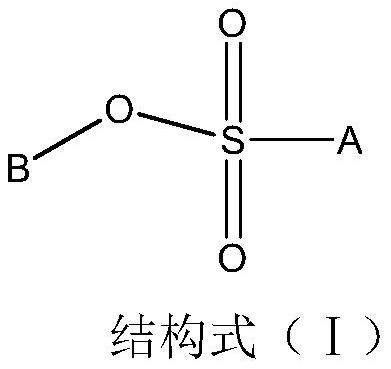

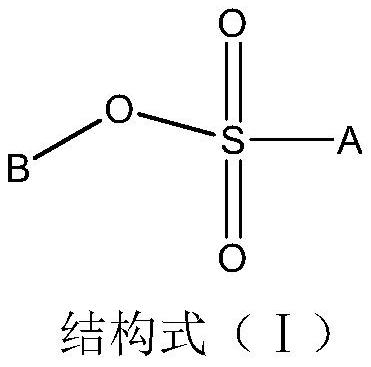

Method used

Image

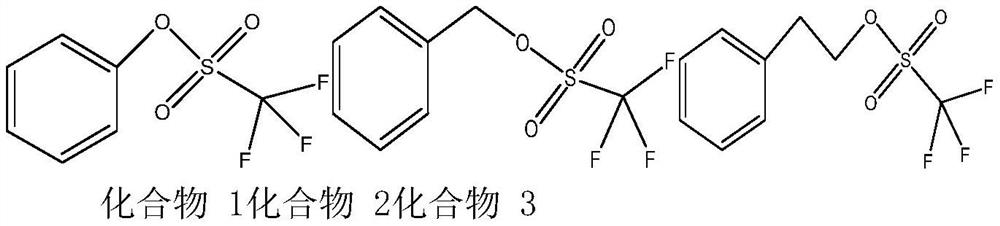

Examples

Embodiment 1

[0028] 1. Preparation of electrolyte: mix ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) according to the mass ratio of EC:DEC:EMC=1:1:1, after mixing Add 1 mol of lithium hexafluorophosphate (LiPF 6 ), after the lithium salt was completely dissolved, 0.5% of compound 1 was added.

[0029] 2. Preparation of the positive electrode sheet: the nickel-cobalt lithium manganate ternary material LiNi 0.6 co 0.2 mn 0.2 o 2 , conductive agent SuperP, binder PVDF, and carbon nanotubes (CNT) are uniformly mixed at a mass ratio of 97.5:1.5:1:1 to make a certain viscosity lithium-ion battery positive electrode slurry, which is coated on the aluminum foil for current collector. The coating weight is 324g / m 2 , after drying at 85°C, cold pressing; then edge trimming, cutting, slitting, and drying at 85°C for 4 hours under vacuum conditions after slitting, and welding the tabs to make a lithium-ion battery positive electrode that meets the requirements ...

Embodiment 10

[0034] 1. Preparation of electrolyte: mix ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) according to the mass ratio of EC:DEC:EMC=1:1:1, after mixing Add 1 mol of lithium hexafluorophosphate (LiPF 6 ), after the lithium salt was completely dissolved, 0.5% of compound 1 was added.

[0035] 2. Preparation of positive electrode sheet: lithium cobalt oxide material LiCoO 2 , conductive agent SuperP, binder PVDF, and carbon nanotubes (CNT) are uniformly mixed at a mass ratio of 97.5:1.5:1:1 to make a certain viscosity lithium-ion battery positive electrode slurry, which is coated on the aluminum foil for current collector. The coating weight is 316g / m 2 , after drying at 85°C, cold pressing; then edge trimming, cutting, slitting, and drying at 85°C for 4 hours under vacuum conditions after slitting, and welding the tabs to make a lithium-ion battery positive electrode that meets the requirements piece.

[0036] 3. Preparation of the negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com