Vanadium pentoxide positive electrode material as well as preparation method and application thereof

A technology of vanadium pentoxide and positive electrode materials, which is applied in the direction of positive electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of active material shedding, capacity drop, etc., and achieve less capacity fading, increased stability, and good ion transmission efficiency and the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] An embodiment of the present invention provides a method for preparing a vanadium pentoxide positive electrode material, comprising the following steps:

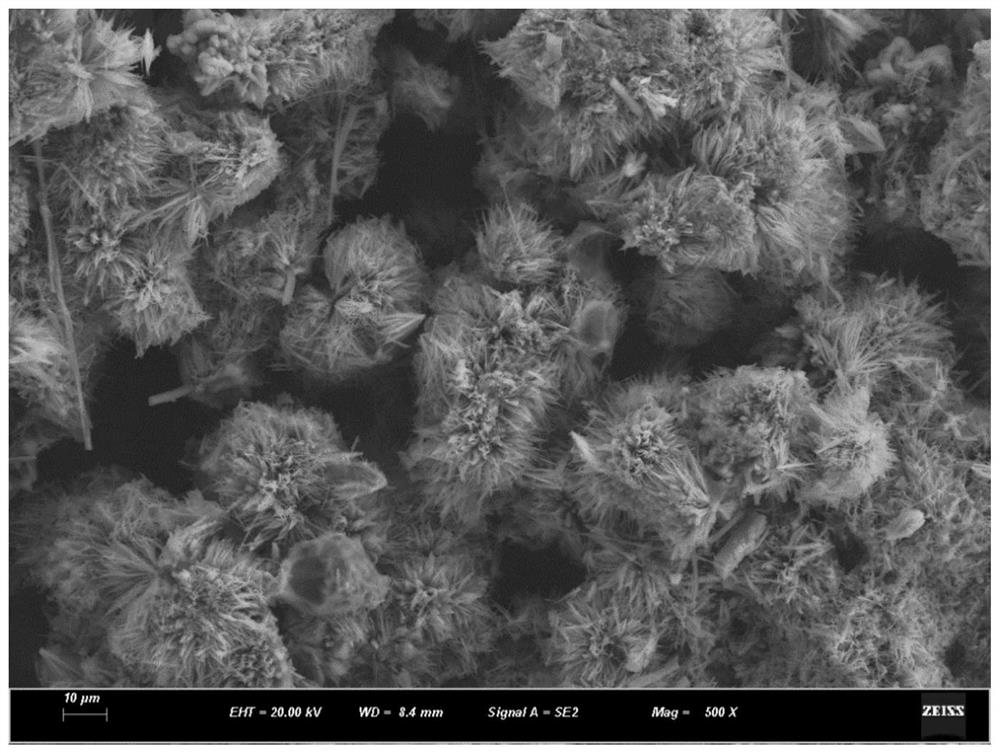

[0036] S1: Add vanadium source and sulfur source to alcohol solvent, heat pretreatment, react, centrifuge, wash and dry to get sea urchin-like VS 4 Precursor;

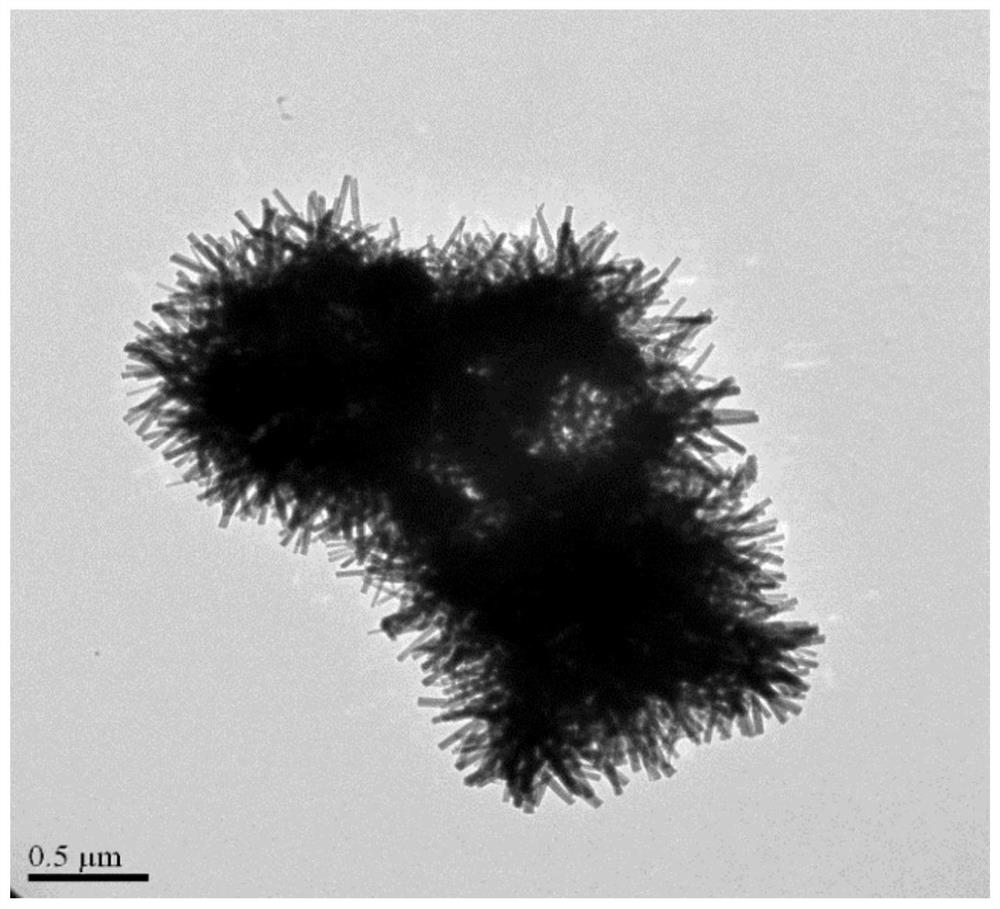

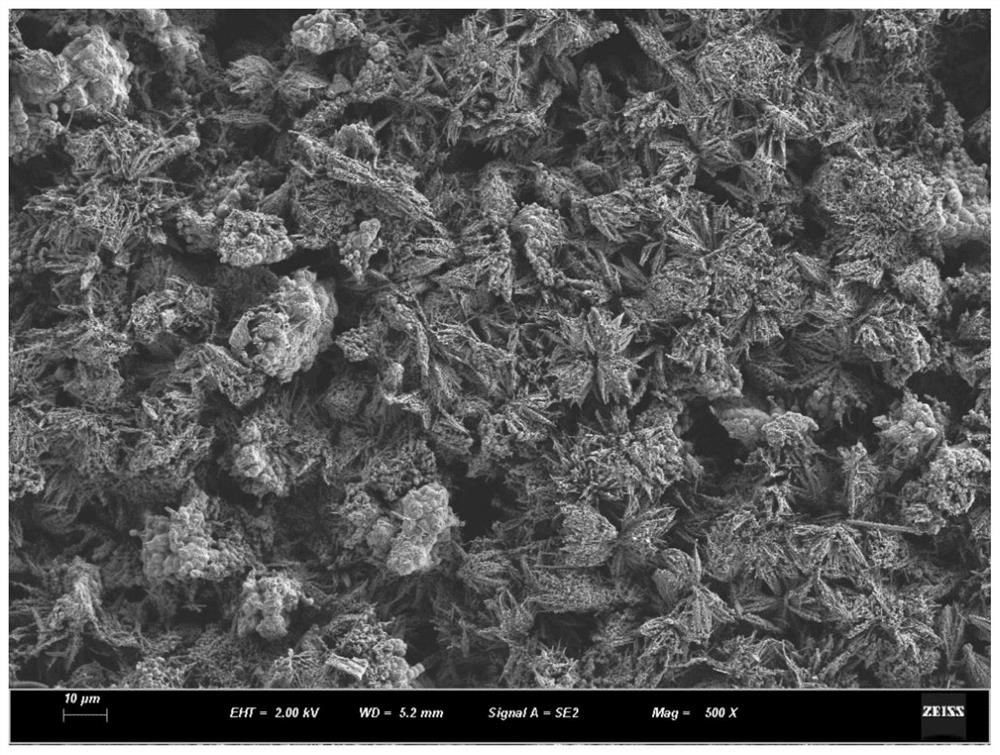

[0037] S2: Put the VS 4 The precursor is sintered to obtain V with a multidimensional hybrid structure 2 o 5 Powder, wherein the multidimensional hybrid structure includes a three-dimensional sea urchin-like structure and a two-dimensional nanosheet structure;

[0038] S3: Set the V 2 o 5 The powder and polypyrrole are dispersed in ethanol, and a block copolymer surfactant is added to obtain a suspension, which is electrospun to obtain V 2 o 5 / polypyrrole fiber, the resulting fiber is calcined under an inert atmosphere to obtain a vanadium pentoxide positive electrode material V 2 o 5 @PPy.

Embodiment 1

[0041] A preparation method of vanadium pentoxide cathode material, comprising the steps of:

[0042] S1: Add ammonium metavanadate and thiourea with a mass ratio of 1:5 to 20 times (mass volume times) methanol, add surfactant P123 (the amount added is the total mass of ammonium metavanadate, thiourea and methanol 3%), carry out preliminary dissolving and mixing, stir and pretreat at 65°C for 30min, the mixed solution turns from light yellow to gray black, then put the pretreated mixed solution into the reaction kettle and react at 155°C for 14h, then centrifuge , and washed with deionized water and ethanol, and the resulting precipitate was dried at 70°C for 12 hours to obtain gray-black sea urchin VS 4 Precursor;

[0043] S2: Apply the above VS 4 The precursor was placed in a box-type sintering furnace and sintered at 200 °C for 2 hours to obtain V with a dual morphology of a three-dimensional nanoflower structure and a two-dimensional nanosheet structure 2 o 5 powder; ...

Embodiment 2

[0046] A preparation method of vanadium pentoxide cathode material, comprising the steps of:

[0047] S1: Add ammonium metavanadate and thioacetamide with a mass ratio of 1:4 to 20 times (mass and volume times) methanol, and add surfactant P123 (addition amount is ammonium metavanadate, thioacetamide 2% of the total mass of methanol) for preliminary dissolution and mixing, stirring and pretreatment at 40°C for 60 minutes, the mixed solution turns from light yellow to gray black, and then put the pretreated mixed solution into the reaction kettle to react at 140°C After 16 hours, centrifuge, wash with deionized water and ethanol, and dry the resulting precipitate at 70°C for 12 hours to obtain gray-black sea urchin VS 4 Precursor;

[0048] S2: Apply the above VS 4 The precursor was placed in a box-type sintering furnace and sintered at 400 °C for 3 hours to obtain V with a dual morphology of a three-dimensional nanoflower structure and a two-dimensional nanosheet structure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com