Polyurethane foam combined explosion-proof device and polyurethane foam material

A technology of polyurethane foam and explosion-proof device, applied in blasting and other directions, can solve the problem that explosion-proof performance needs to be further improved, and achieve the effect of reducing the space required for storage, prolonging the interaction time, and improving the efficiency of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A polyurethane foam material, said material is prepared by the above method:

[0051] (1) Preparation of component A: 100 parts by mass of polyoxypropylene polyol, 15 parts by mass of blowing agent, 1.5 parts by mass of foam stabilizer, 1.2 parts by mass of catalyst, 2 parts by mass of chain extender, 3 parts by mass of surface silanization Carbon black and 1 mass part of multi-walled carbon nanotubes are uniformly mixed to obtain component A; wherein, the blowing agent is H with a mass ratio of 3:1 2 O and fluorotrichloromethane; the catalyst is dibutyltin dilaurate; the chain extender is diethyltoluenediamine, ethylene glycol and 1,4-butanediol in a mass ratio of 5:2:2; multi-wall The carbon nanotubes have a diameter of 20-40nm and a length of 1-2μm;

[0052] (2) Preparation of component B: add 0.01 mass part of polymerization inhibitor to 50 mass parts of diphenylmethane diisocyanate (MDI) and 50 mass parts of polyurethane tetrahydrofuran polyol to obtain B componen...

Embodiment 2

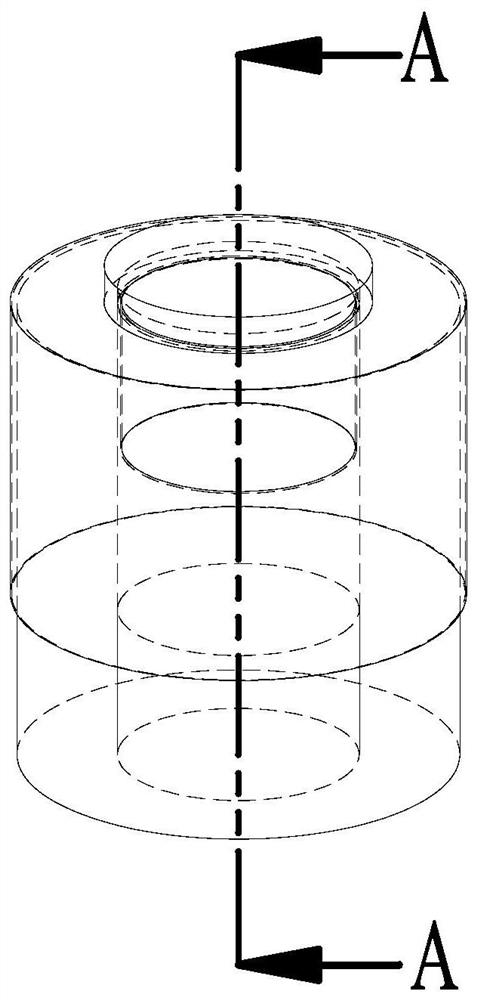

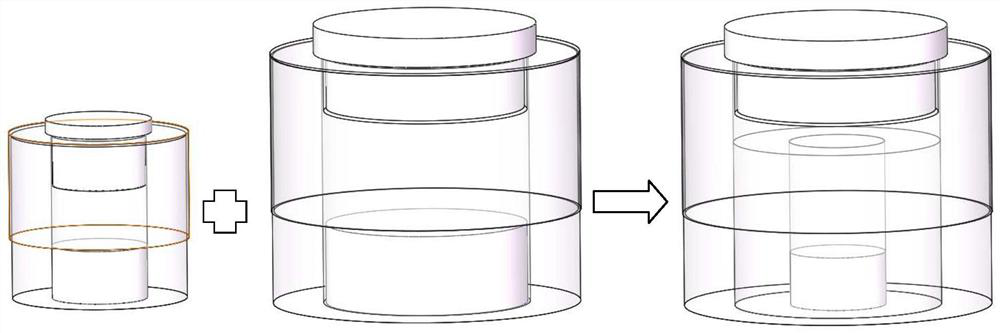

[0059] A polyurethane foam combined explosion-proof device, including a cylinder 4 and a cover, the material of the cylinder 4 is polyurethane foam, and the cover includes a polyurethane foam cover 3 and a liquid cover 1, wherein the polyurethane foam cover 3 is located The upper end of the cylinder body 4 is embedded inside the cylinder body 4. The depth of the polyurethane foam cover 3 embedded in the cylinder body is adjustable. The liquid cover 1 is located above the cylinder body 4 and covers the polyurethane foam cover 3. At the same time, the liquid cover 1 and polyurethane Air gaps 2 are left between the foam covers 3 .

[0060] The liquid in the liquid cover 1 is water. The cylinder body 4 and the polyurethane foam cover 3 both use the polyurethane foam material described in Example 1.

[0061] The explosion-proof device also includes a protective base 5, which is located at the inner bottom of the cylinder 4; the material of the protective base 5 is the polyurethane...

Embodiment 3

[0074] In this embodiment, the explosive is 125g of TNT, with a radius of 25mm and a height of 40mm.

[0075] Adopt the device described in embodiment 2 and comparative example 3 to carry out the numerical simulation test of explosion shock to described explosive respectively, the shock wave pressure contrast cloud picture of different moments after described explosive explodes is as follows Figure 4 As shown, compared with the device described in Comparative Example 3, the development direction of the shock wave at the top of the device described in Example 2 is guided, and the strong shock wave reflected and superimposed inside the protective structure is dispersed to the circumferential direction between the polyurethane foam cover and the cylinder. The gap is leaked, and the liquid layer on the outside has a large wave impedance, which can quickly absorb the shock wave leaked from the polyurethane layer of the cover body; Leakage occurs at the contact interface between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com