Novel transmission device and shaver

A transmission device and shaver technology, which is applied to the transmission device, gear transmission device, transmission device parts, etc., can solve the problems of complex assembly, unsightly appearance, and small difference in shape, so as to ensure transmission efficiency and better waterproof effect Excellent effect with great difference in appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

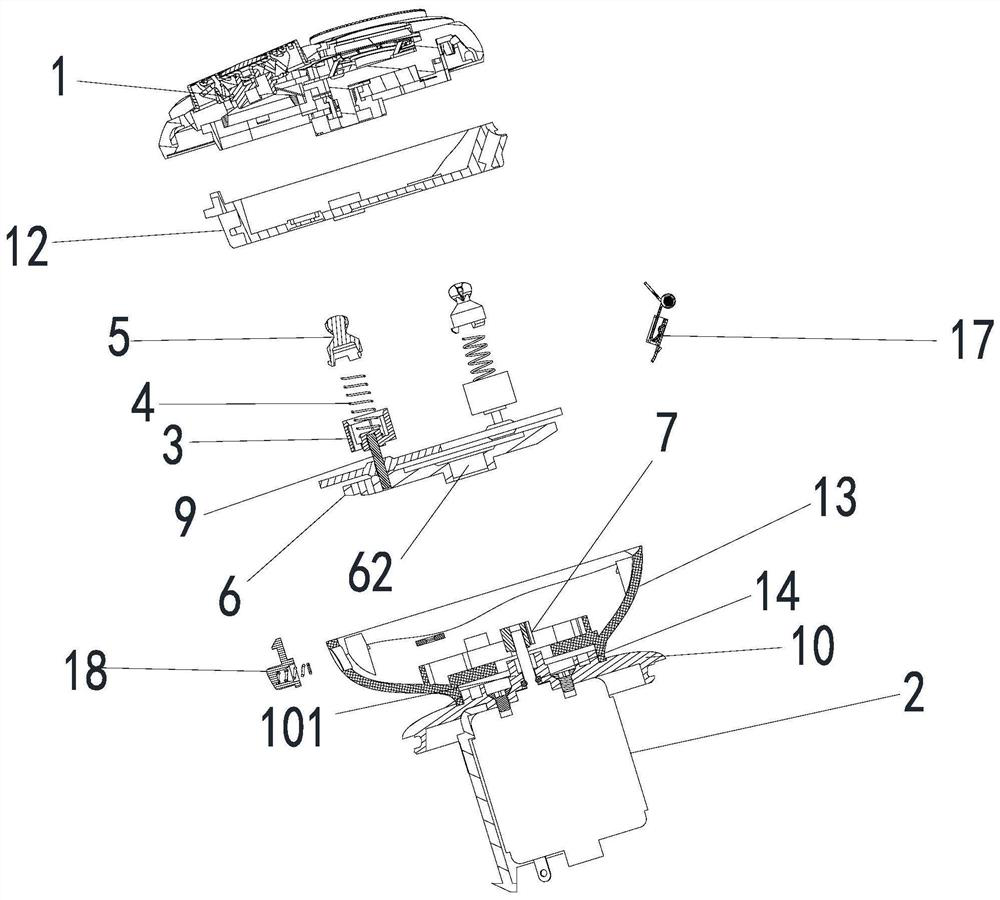

[0030] see Figure 1-7 : A new type of transmission device, related to a shaver, including a cutting assembly 1 installed in the head of the shaver, a single-stage transmission and a drive motor 2 installed in the handle of the shaver, the drive motor 2 directly The single-stage transmission device is driven to rotate, and the single-stage transmission device drives the upper cutting assembly 1 to rotate and cut.

[0031] In this embodiment, the transmission mechanism is canceled inside the handle, and the single-stage transmission device of the shaver head is directly connected with the motor for transmission, which greatly simplifies the transmission device, greatly reduces the cost, and at the same time, the transmission efficiency is obviously improved.

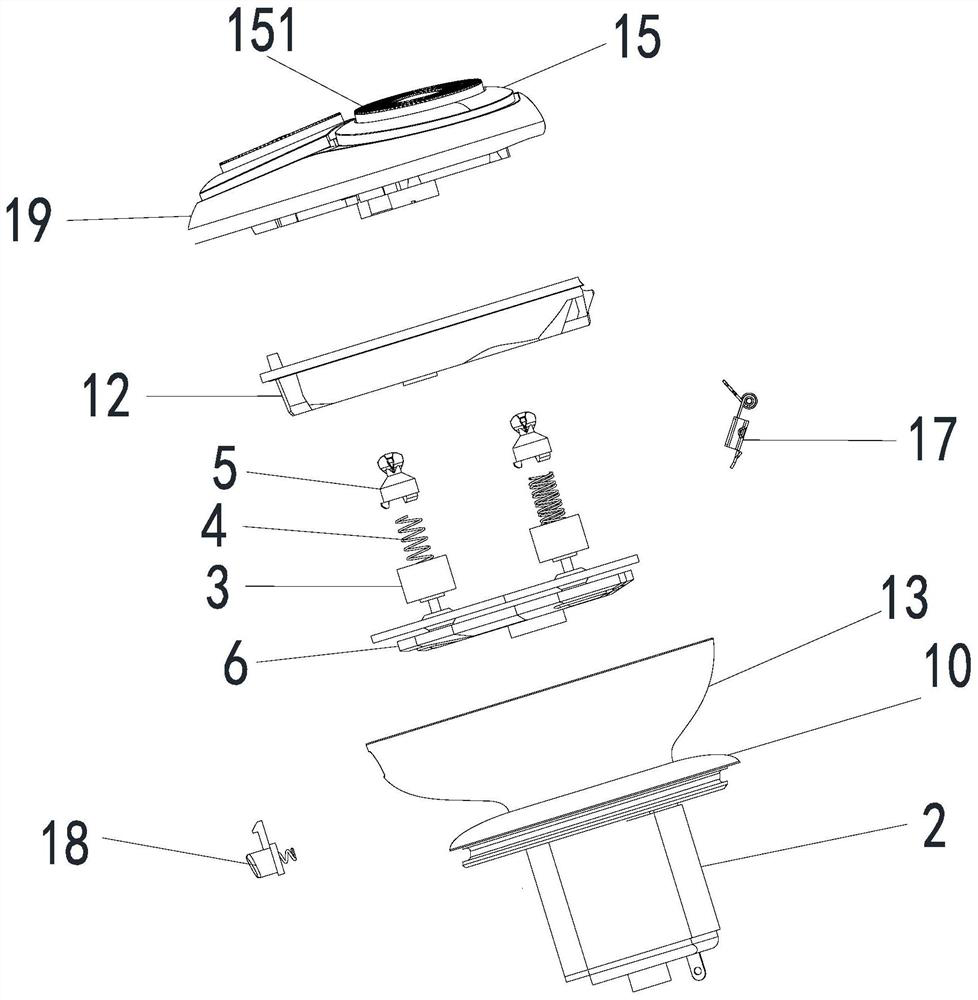

[0032] see figure 1 , Figure 4-5: In a specific example, the single-stage transmission device includes a positioning shaft 3, a rotating shaft spring 4, a rotating head 5, a gear frame 6, a driving gear 7 and at least ...

Embodiment 2

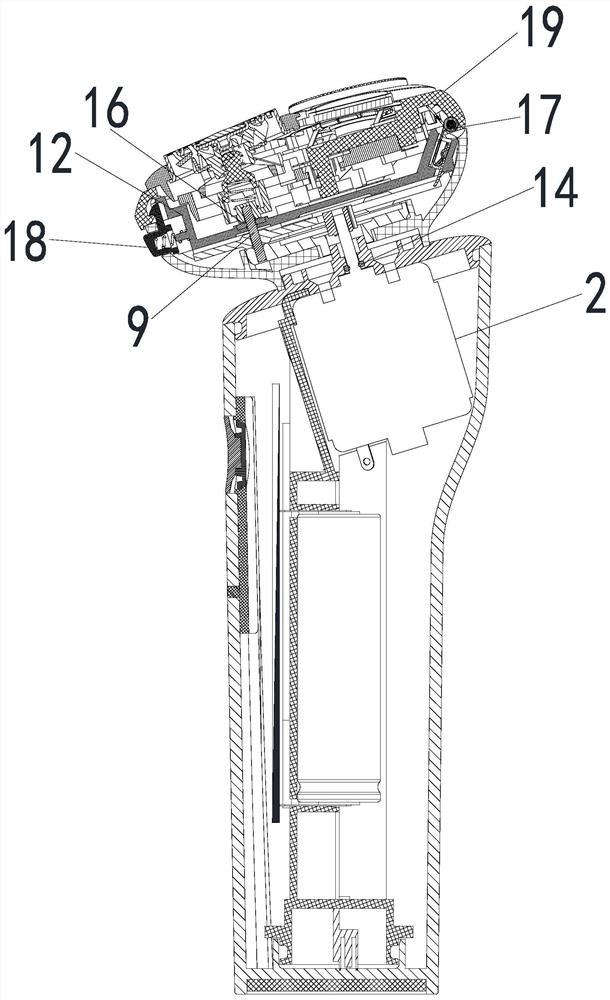

[0040] see Figure 3-4 : present embodiment also discloses a kind of razor, described razor comprises as above-mentioned novel transmission device, is provided with dust-proof soft rubber ring 16 on described frame card 12, dust-proof soft rubber ring 16 and rotating shaft 9 , Frame card 12 interference fit.

[0041] In this embodiment, the dust-proof soft rubber ring is arranged on the frame card, and the dust-proof soft rubber ring is an interference fit with the steel shaft of the rotating shaft and the frame card. Therefore, when the shaver is used, beard residue will not fall into the frame card and the frame card Transmission components between bottom shells. Ensure that the transmission components will not cause abnormal noise and instability due to foreign objects.

[0042] In a specific example, a hinge 17 and a head cover button assembly 18 are also included, the rear end of the frame card 12 is connected to the rear end of the head cover 19 of the shaver head thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com